信頼の中国超硬チップメーカー

最適性能のためのプレミアム中国超硬インサート

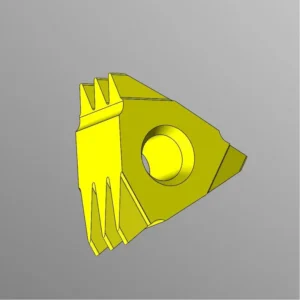

高品質の超硬チップを提供するONMY Toolsへようこそ。超硬チップのリーディングサプライヤーとして、当社は最も要求の厳しい加工要件を満たすプレミアム中国超硬チップの提供を専門としています。一流の旋削チップを含む当社の幅広い製品群により、お客様の製造ニーズに最適なソリューションを確実に見つけることができます。

オンミーツールへようこそ

今日の競争の激しい製造現場では、精度が成功の鍵です。超硬チップは、機械加工において最高レベルの精度と効率を達成するために重要な役割を果たします。経験豊富な中国の超硬チップサプライヤーとして、弊社は、小さいながらも強力なこの部品が、お客様の生産工程に与える重要な影響を理解しています。

当社の中国製超硬チップは、卓越した性能、耐久性、費用対効果を実現するように設計されています。旋削用チップ、フライス用チップ、または特殊なソリューションのいずれをお探しでも、当社はお客様の仕様に正確に対応する専門知識と製品群を取り揃えています。

中国ONMY超硬インサートを選ぶ理由

比類ない品質と精度

ONMY Toolsでは、品質と精度の最高基準を満たす超硬チップを提供することに誇りを持っています。当社のチップは、一貫した性能と長い工具寿命を確保するために、高度な技術と高級材料を使用して製造されています。各チップは、お客様の手に渡る前に、当社の厳格な基準を満たすことを保証するために、厳格な品質管理チェックを受けます。

包括的な製品群

超硬チップのリーディングサプライヤーとして、様々な加工用途に対応する豊富なチップを取り揃えています。汎用の旋削用チップから特殊なフライス加工やドリル加工用チップまで、当社のカタログは形状、サイズ、材種を幅広く網羅しています。この多様性により、お客様の特定のニーズに最適なチップを見つけることができ、加工プロセスを最適化し、全体的な生産性を向上させることができます。

費用対効果の高いソリューション

信頼できる中国超硬チッププロバイダーとしての当社の地位は、品質に妥協することなく、非常に競争力のある価格を提供することを可能にしています。ターニングインサートサプライヤーとして当社をお選びいただくことで、中国製造のコストメリットと厳格な品質管理対策のメリットを享受していただけます。これにより、お客様の生産が要求する高い水準を維持しながら、工具コストを削減することができます。

対象業界

信頼できる中国の超硬チップサプライヤーとして、弊社は以下のような幅広い産業に対応しています:

自動車

エンジン部品、トランスミッション部品などにインサートを提供

航空宇宙

航空機や宇宙船の重要部品に高精度チップを供給

石油・ガス

掘削装置やパイプライン部品に耐久性のあるインサートを提供

一般製造業

さまざまな分野の多様な加工ニーズに対応

メディカル

医療機器やインプラントの製造に精密インサートを提供

金型

複雑な金型製作用の専用インサートを提供

提携のメリット

- 専門技術サポート

当社の経験豊富なエンジニアチームは、お客様の特定の用途に適した超硬チップの選定をいつでもサポートいたします。包括的な技術サポートを提供し、加工プロセスの最適化や、遭遇する可能性のある問題のトラブルシューティングを支援します。

- 迅速で確実な配達

当社は、お客様の生産スケジュールを維持する上で、タイムリーな納品が重要であることを理解しています。超硬インサートサプライヤーとして、当社は標準インサートの豊富な在庫を維持し、カスタムオーダーには迅速な納期を提供します。当社の効率的なロジスティクス・ネットワークは、お客様の注文が迅速に届くことを保証し、ダウンタイムを最小限に抑え、お客様の業務を円滑に維持します。

- カスタマイズ機能

製造工程はそれぞれ異なり、既製のソリューションでは不十分な場合もあります。当社の社内研究開発チームは、お客様と協力して、特定の要件に完全に適合するカスタム超硬チップを設計・製造することができます。この柔軟性により、最も困難な加工タスクにも自信を持って取り組むことができます。

- 競争力のある価格設定

中国の超硬チップサプライヤーとして、当社は厳格な品質基準を維持しながら、中国製造のコスト優位性を活用しています。これにより、製品の性能と信頼性を損なうことなく、非常に競争力のある価格を提供することができます。ターニングインサートサプライヤーとして当社をお選びいただくことで、工具コストを大幅に削減し、収益を改善することができます。

品質へのこだわり

ONMY TOOLINGSでは、品質がすべての中心にあります。評判の高い超硬インサートサプライヤーとして、当社は生産プロセス全体で厳格な品質管理対策を実施しています。当社の製造施設には最先端の試験装置が設置されており、各チップが出荷前に当社の厳しい基準を満たすことを保証しています。

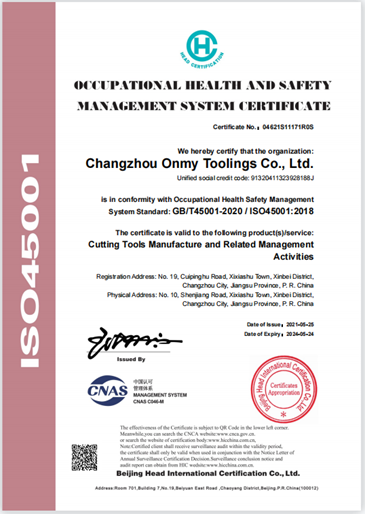

当社はISO9001:2015およびISO45001の認証を取得しており、強固な品質管理システムの維持に努めています。さらに、当社の製品はANSIやDINなどの国際規格に準拠しており、さまざまな加工システムでの互換性と性能を保証しています。

世界30カ国以上のお客様

ジェームズ・キング

ジョアンナ・フォックス

フェリシティ・トランプ

ご注文の流れ

ONMY Toolsへのご注文はシンプルで簡単です:

- 製品情報については、オンラインカタログをご覧いただくか、営業担当までお問い合わせください。

- ご希望の超硬チップをお選びいただくか、カスタム見積もりをご依頼ください。

- 具体的なご要望と必要な数量をお知らせください。

- ご注文内容をご確認ください。

- ご希望のお支払い方法を選択し、お取引を完了してください。

- ご注文の確認とお届け予定日をお受け取りください。

- 貨物を追跡し、到着に備えてください。

大量のご注文や定期的なご注文には、合理化されたプロセスと潜在的なボリュームディスカウントを提供します。お客様の具体的なニーズについては、営業チームにお問い合わせください。