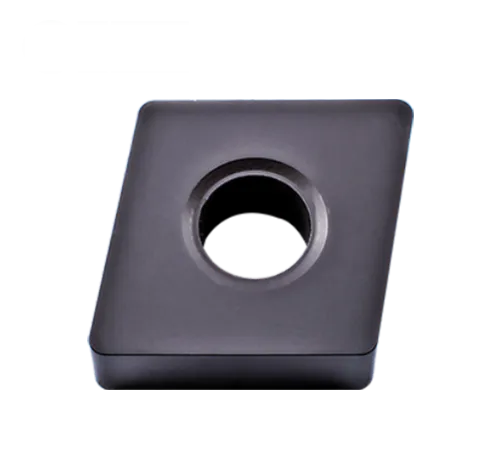

CNMA Torna Ucu

CNMA uç açısı: 0° Negatif eğimli uç ve talaş kırıcı yok;

80° eşkenar dörtgen tornalama ucu;

Birincil iş parçası malzemesi: Sert malzeme; dökme demir; çelik

Birincil iş parçası malzeme kodu: P; H; K

Uç tutma yöntemi: Pim; Kelepçe;

Kırıcı uygulaması: Kaba işleme, yarı ince işleme, ince işleme

Eşleştirme cnma eki alet tutucu: PCBNR/L, PCLNR/L, MCLNR/L, MCBNR/L;

Derece: Hem PVD hem de CVD;

Malzeme: Tungsten Karbür ;

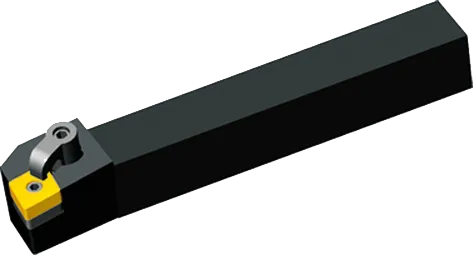

CNMA kesici uç takım tutucu

MCLNR/L

CNMA insert Giriş:

CNMA Karbür Uçlar: Temel Bilgiler

- Şekil: Eşkenar dörtgen (elmas), 80 derecelik bir iç açıya sahiptir.

- Açıklık Açısı: 0 derece

- Kesme Kenarları: Çift taraflı, maliyet etkinliği için kesici uç başına iki kesme kenarı sunar.

- Çip Kırıcı Geometriler: Çeşitli üreticilerin çok çeşitli talaş kırıcı stilleri mevcuttur. Bunlar belirli malzemelere ve işleme operasyonlarına (kaba işleme, ince işleme vb.) göre uyarlanmıştır.

- Anahtar Kullanımlar: Öncelikle genel tornalama işlemleri ve çeşitli malzemeler üzerinde bazı kaplama işleri için kullanılır.

CNMA Uçlarının Kullanıldığı Yaygın Malzemeler

- Dökme Demir: Birçok dökme demir uygulaması için uygundur.

CNMA Uçların Avantajları

- Uygun maliyetli: Çift taraflı tasarımları sayesinde kesici uç başına daha uzun takım ömrü sunar.

- Çok yönlü: Çok çeşitli kaliteler ve talaş kırıcılar, bunları birçok işleme uygulaması için uygun hale getirir.

- Güçlü Geometrik Şekil: 80 derecelik elmas şekli, boyutlarına göre güç ve sağlamlık sağlar.

Önemli Hususlar

- Notu Malzemenizle Eşleştirin: Doğru kesici uç kaplamasını ve alt tabaka bileşimini seçmek, kestiğiniz özel malzemede optimum takım ömrü ve performansı için çok önemlidir.

- Doğru Çip Kırıcıyı Seçin: Talaş kırıcı geometrisi, talaşların nasıl oluştuğunu ve kırıldığını önemli ölçüde etkiler. Malzemeye ve işleme operasyonunun türüne göre seçilmelidir.

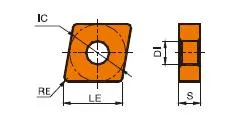

CNMA Kesici Uç Boyutları (ISO)

| TİP | CNMA INSERT DİYAMENTASYONLARI (mm) | ||||

|---|---|---|---|---|---|

| LE | IC | S | DI | RE | |

| CNMA120404 | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 |

| CNMA120408 | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

| CNMA120412 | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 |

| CNMA120416 | 12.9 | 12.7 | 4.76 | 5.16 | 1.6 |

| CNMA160608 | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 |

| CNMA160612 | 16.1 | 15.875 | 6.35 | 6.35 | 1.2 |

| CNMA160616 | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 |

| CNMA190612 | 19.3 | 19.05 | 6.35 | 7.94 | 1.2 |

| CNMA190616 | 19.3 | 19.05 | 6.35 | 7.94 | 1.6 |

Örnek: CNMA 120408

- 12: Yazılı Daire (IC) 12,7 mm (yaklaşık 0,5 inç)

- 04: Kalınlık 4,76 mm (yaklaşık 0,187 inç)

- 08: Köşe yarıçapı 0,8 mm (yaklaşık 0,031 inç)

Anahtar Boyutlar

Yazıtlı Daire (IC): Ek parçanın içine sığan en büyük dairenin çapı. Yaygın IC boyutları şunları içerir:

- 12,7 mm (0,5″)

- 16mm (0,63″)

- 19,05 mm (0,75″)

Kalınlık: Kesici uç mukavemetini ve kullanılabilir kesme kenarı sayısını etkiler. Yaygın kalınlıklar şunları içerir:

- 3,18 mm (0,125″)

- 4,76 mm (0,187″)

- 6,35 mm (0,25″)

Köşe Yarıçapı: Yüzey kalitesini ve kesme kenarındaki mukavemeti etkiler. Yaygın boyutlar şunları içerir:

- 0,4 mm (0,016″)

- 0,8 mm (0,031″)

- 1,2 mm (0,047″)

Karbür Uçların Arkasındaki Bilim: Nasıl Yapıldıkları ve Neden Bu Kadar Güçlü Oldukları

Karbür kesici uçlar, mevcut en çok yönlü ve dayanıklı kesme aletlerinden bazılarıdır. Peki ama nasıl üretiliyorlar? Ve onları bu kadar güçlü yapan nedir? Bu videoda, tungsten karbürün özelliklerinden üretim sürecine kadar karbür kesici uçların arkasındaki bilimi keşfedeceğiz.

Üretim Kapasitemiz