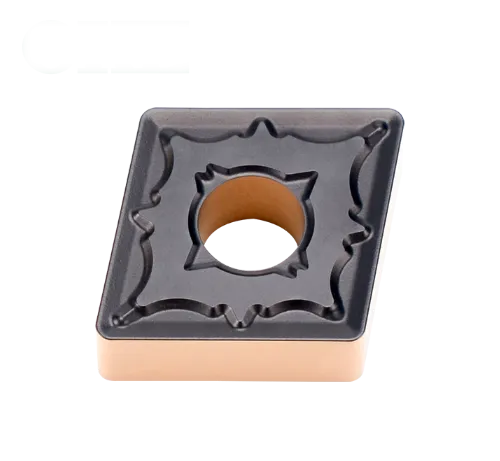

CNMG刀片

CNMG insert angle:0° Negative rake insert with double-sided chipbreaker;

80°菱形车削刀片;

Primary workpiece material: the best cnmg insert for stainless steel, brass, bronze, aluminium and cast iron ;

Breaker application: rough, heavy, semi-finshing;

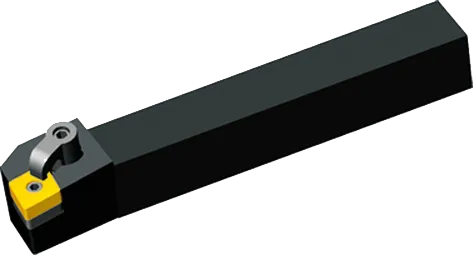

Matching cnmg insert tool holder: PCBNR/L, PCLNR/L, MCLNR/L,MCBNR/L;

牌号:PVD 和 CVD;

Material : Tungsten carbide;

CNMG insert can deal with multiple operations by combining different chip breakers and grades.

CNMG insert specification

The CNMG Insert dimensions have four major categories which are (ISO standard)CNMG120404, CNMG120408, CNMG120412, and CNMG190616;(ANSI standard)CNMG332,CNMG431,CNMG432,CNMG433,CNMG543,CNMG643.

The multiple types of dimensions enable to meet different customer requirements and working conditions.

CNMG insert tool holder

MCLNR/L

CNMG insert Introduction

CNMG Inserts: The Essentials

- 形状: 夹角为 80 度的菱形(菱形)。

- 间隙角: 0 degrees.

- 切削刃: 双面,每个刀片提供两个切削刃,以实现成本效益。

- 断屑槽几何形状: A wide range of chipbreaker styles from various manufacturers, tailored to specific materials and machining operations (roughing, finishing, etc.).

- 主要用途: Ideal for a variety of turning operations, including facing and profiling, on a wide range of workpiece materials.

Common Materials CNMG Inserts are Used For

- 钢材: 各种钢种,包括碳钢和合金钢。

- 不锈钢: CNMG inserts can effectively machine different stainless steel types.

- 铸铁: 适用于许多铸铁应用。

- 一些高温合金: 取决于具体的合金和牌号。

Advantages of CNMG Inserts

- 性价比高: 由于其双面设计和广泛的可用性。

- 多才多艺的: An extensive range of grades and chipbreakers make them suitable for many machining applications.

- 良好的切屑控制: 精心设计的断屑槽可确保有效的切屑流动并保护工件、刀具和机器。

- Strong Geometric Shape: The 80-degree diamond shape provides strength and rigidity for various cutting scenarios.

重要考虑因素

- 将等级与您的材料相匹配: 选择正确的刀片涂层和基体成分对于您所切削的特定材料的最佳刀具寿命和性能至关重要。

- 选择正确的断屑槽: 断屑槽的几何形状显着影响切屑的形成和断屑方式。应根据材料和加工操作类型进行选择。

- 机器刚性: Ensure your machine has enough power and rigidity to handle the cutting forces CNMG inserts can generate.

CNMG Insert Dimensions (ISO)

| ISO 名称 | 内切圆 (IC) | 厚度 | 拐角半径 |

|---|---|---|---|

| CNMG 120404 | 12.7mm (0.5") | 4.76mm (0.187") | 0.4mm (0.016") |

| CNMG 120408 | 12.7mm (0.5") | 4.76mm (0.187") | 0.8mm (0.031") |

| CNMG 120412 | 12.7mm (0.5") | 4.76mm (0.187") | 1.2mm (0.047") |

| CNMG 160608 | 16mm (0.63") | 6.35mm (0.25") | 0.8mm (0.031") |

| CNMG 160612 | 16mm (0.63") | 6.35mm (0.25") | 1.2mm (0.047") |

| CNMG 190612 | 19.05mm (0.75") | 6.35mm (0.25") | 1.2mm (0.047") |

Example: CNMG 120408

- 12: Inscribed Circle (IC) of 12.7mm (approx. 0.5 inches)

- 04: Thickness of 4.76mm (approx. 0.187 inches)

- 08: 圆角半径为 0.8 毫米(约 0.031 英寸)

主要尺寸

内切圆 (IC): 适合插入件的最大圆的直径。常见的 IC 尺寸包括:

- 12.7毫米(0.5″)

- 16毫米(0.63″)

- 19.05mm (0.75″)

厚度: 影响刀片强度和可用切削刃的数量。常见的厚度包括:

- 3.18毫米(0.125″)

- 4.76毫米(0.187″)

- 6.35毫米(0.25″)

拐角半径: 影响切削刃处的表面光洁度和强度。常见尺寸包括:

- 0.4毫米(0.016″)

- 0.8毫米(0.031″)

- 1.2mm (0.047″)

F.A.Q.

Shape:

TNMG: Triangular insert with a 60-degree included angle.

CNMG: Diamond-shaped insert with an 80-degree included angle.

Cutting Edge Strength:

TNMG: Triangular inserts with six cutting edges are very stable and are suitable for roughing and semi-finishing operations.

CNMG:Compared with TNMG insert, it has 8 cutting edges, which is more economical; the top angle of 80 degrees has more stability; it is suitable for roughing and semi-finishing.

1. Shape: CNMG inserts are diamond-shaped indexable cutting tool inserts with an included angle of 80 degrees.

2. Material: They are usually made from tungsten carbide, which is very hard and wear-resistant. CNMG inserts can often have coatings added to enhance their performance, like wear resistance or improved chip flow.

3. Usage: CNMG inserts are used in turning operations on lathes to shape and cut materials like steel, stainless steel, cast iron, and non-ferrous metals.

4. Mounting: The inserts are held securely in a toolholder, providing multiple cutting edges.

CNMG insert geometry :

• C: Diamond shape (80-degree included angle)

• N: Negative rake angle (usually provides a stronger cutting edge)

• M: Medium tolerance class (a general purpose tolerance for fit and precision)

• G: Ground finish (indicates the surface of the insert has been ground for accuracy)

Advantages of CNMG Inserts:

• Strength: The diamond shape and 80-degree angle provide four robust cutting edges, making them great for heavier machining.

• Versatility: They can be used for various turning operations like roughing, semi-finishing, and even some finishing work.

• Cost-effective: Multiple cutting edges per insert improve their lifespan and reduce tooling costs.

Yes, a CNMG 543 insert is thicker than a CNMG 433 insert. Here’s why:

In a CNMG designation, the third digit in the size code represents the insert thickness.

- CNMG 433: The “3” indicates a thickness of 3/16″。

- CNMG 543: The “5” indicates a thickness of 5/16″。

Therefore, the CNMG 543 is thicker than the CNMG 433.

Let me know if you’d like to compare any other insert thicknesses!

Choosing the best CNMG insert grade for 4340 steel depends on several factors, including:

操作类型:

- Roughing: Requires an insert grade with high toughness and wear resistance to withstand heavy cutting forces and chip loads.

- Finishing: Prioritizes surface finish, so a harder, finer-grained grade is better. You’ll need to balance this with wear resistance.

Specific 4340 Properties:

- Heat Treatment: Has the 4340 been hardened? Harder 4340 will require even tougher insert grades, possibly with special coatings.

Here are some commonly recommended CNMG insert grades for 4340, along with their strengths:

General-Purpose Grades:

- CVD Coated Grades (e.g., PVD TiAlN): Offer good balance of toughness and wear resistance for roughing and semi-finishing.

- PVD Coated with Alumina (Al2O3) layer: Provides better heat resistance, good for higher speeds in 4340 with moderate hardness.

Finishing-Focused Grades

- Fine-Grained Uncoated Grades: For improved surface finish in softer 4340, but wear faster.

- CBN (Cubic Boron Nitride): Super-hard material for excellent finish on hardened 4340, but more expensive and brittle.

Popular Insert Manufacturers and Grade Examples

- Sandvik Coromant: GC4415, GC4425 (CVD coated grades versatile for 4340)

- Kennametal: KCP25B, KC5010 (good for hardened 4340)

- Walter: WPP10S, WPP20S (general-purpose, good starting point)

- Mitsubishi: UE6110 (uncoated fine grain for finishing)

重要考虑因素

- 断屑槽样式: Match the chipbreaker to your operation and the 4340’s hardness to manage chip formation and avoid cutting edge damage.

- 冷却液: Proper coolant use is essential, especially for harder 4340 workpieces.

Recommendation:

Start with a versatile CVD-coated grade suitable for your 4340 steel’s hardness. Always consult manufacturer data sheets and machining recommendations for your specific insert grade.

Let me know if you have details on the following, and I can give you a more tailored insert grade recommendation:

- Type of turning operation (roughing, finishing)

- Hardness of your 4340 material

- Any specific surface finish requirements

Yes, a CNMG 543 insert does have a defined thickness. Here’s how to understand it:

In the CNMG designation, the third number in the size code represents the insert’s thickness in sixteenths of an inch.

- CNMG 543: The “5” represents a thickness of 5/16″ of an inch.

Let me know if you’d like to know the thickness of other CNMG inserts or have a specific comparison in mind!

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

硬质合金刀片是目前最通用、最耐用的切削工具之一。但它们是如何制作的呢?是什么让他们如此强大?在本视频中,我们将探索硬质合金刀片背后的科学,从碳化钨的特性到制造工艺。

我们的生产能力