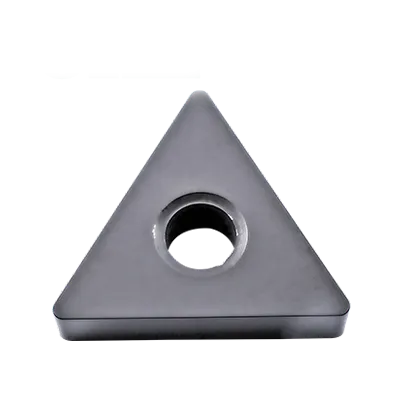

TNMA插入物

TNMA insert angle: 60°Triangle carbide insert; 0° Negative Rake Insert and double-sided no chipbreaker;

Breaker Application: cast iron machining;

TCMA insert inscribed circle (IC) of 9.525mm/12.7mm, thickness of 4.76mm, and corner (nose) radius of 0.4mm/0.8mm/1.2mm/1.6mm;

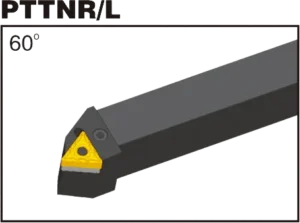

Matching TNMA insert Tool Holder: PTFNR/L,PTTNR/L,PTGNR/L,MTGNR/L,MTJNR/L,MTFNR/L;

TNMA Insert can deal with multiple operations by combining different grades;

材质:碳化钨;

产品介绍

TNMA insert is a triangular 60° angle without chipbreaker specially designed for hard material machining, mainly used in cast iron machining, with good triangular stability, the negative type insert can effectively utilise 6 cutting edges, economical and efficient.

TNMA insert Specification

TNMA Designation

- 电话: Triangular shape.

- N: Negative rake angle (provides stronger cutting edge).

- 中号: Tolerance class (indicates precision of inscribed circle and thickness). Typically +/- 0.13mm.

- A: With cylindrical hole, without chipbreaker.

Common TNMA Dimensions

Similar to TCMT inserts, TNMA inserts use numbers to signify size:

TNMA 33X:

- Inscribed Circle (IC): 0.375″ (3/8″)

- Thickness: 0.125″ (1/8″)

- X represents nose radius in sixteenths of an inch (e.g., 1 = 1/32″)

TNMA 43X:

- Inscribed Circle (IC): 0.5″ (1/2″)

- Thickness: 0.188″ (3/16″)

- X represents nose radius

TNMA insert holder

MTJNR/L

TNMA carbide Insert Dimensions (ISO and ANSI)

| ISO TYPE | ANSI TYPE | 这 | 我知道了 | S | 从 | 关于 |

|---|---|---|---|---|---|---|

| TNMA160404 | TNMA 331 | 16.5 | 9.525 | 4.76 | 3.81 | 0.4 |

| TNMA160408 | TNMG332 | 16.5 | 9.525 | 4.76 | 3.81 | 0.8 |

| TNMA160412 | TNMG 333 | 16.5 | 9.525 | 4.76 | 3.81 | 1.2 |

| TNMA220408 | TNMG432 | 22 | 12.7 | 4.76 | 5.16 | 0.8 |

| TNMA220412 | TNMG433 | 22 | 12.7 | 4.76 | 5.16 | 1.2 |

| TNMA220416 | TNMG434 | 22 | 12.7 | 4.76 | 5.16 | 1.6 |

Example: TNMA 432

- 电话: Triangular

- N: Negative rake angle

- 中号: Tolerance class

- A: 60° included angle

- 4: Inscribed circle of 0.5″ (1/2″)

- 3: Thickness of 0.188″ (3/16″)

- 2: Nose radius of 0.0625″ (1/16″) – good for general purpose work

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

硬质合金刀片是目前最通用、最耐用的切削工具之一。但它们是如何制作的呢?是什么让他们如此强大?在本视频中,我们将探索硬质合金刀片背后的科学,从碳化钨的特性到制造工艺。

我们的生产能力