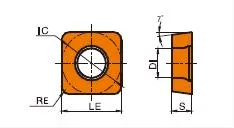

SCMT车刀

SCMT刀片角度:90°方形,7°正前角刀片,带单面断屑槽;

旋入式嵌件;

高抛光方形车削刀片适用于多种材料;

方形硬质合金刀片;

断屑槽应用:半精加工 & 精加工;

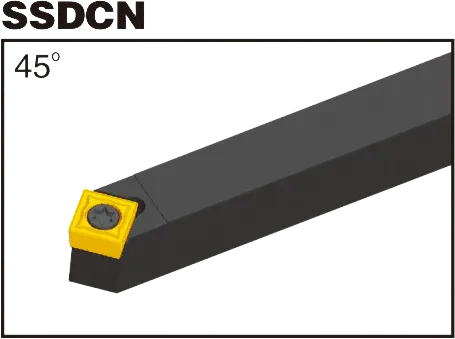

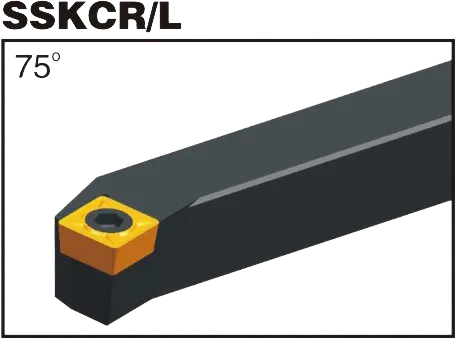

配套车刀刀柄:SSDCN、SSKCR/L;

SCMT刀片可以通过组合不同的断屑槽和牌号来处理多种操作;

材质:碳化钨;

规格

SCMT 在外圆车削方面表现出色。

其集成断屑槽可优化切屑控制并降低切削阻力,从而实现卓越的加工性能。

理想的切屑形成可防止工件损坏、最大限度地减少振动并延长刀具寿命。

降低切削阻力还可以减少负载和热量产生,进一步保护您的刀具投资。

SCMT 插入 含义

了解 SCMT 插入代码

- 小号: 形状: 方形

- C: 间隙角:7度

- 中号: 公差:中等公差为标准,但也可能提供其他精度公差。

- 电话: 断屑槽样式 & 孔配置。该字母表示特定的断屑槽几何形状以及刀片是否有孔。断屑槽种类繁多,且因制造商而异。

- 数字:

- 前两位数字: 内切圆 (IC) 直径(以毫米为单位)。要获得近似的英寸当量,请将此数字除以 25.4。

- 接下来的两位数字: 厚度以毫米为单位。除以 25.4 即可转换为英寸。

- 最后两位数字: 圆角半径(以毫米为单位)。要转换为英寸,请除以 25.4。

SCMT 刀片架

SCMT 刀片尺寸 (ISO)

| ISO 名称 | 内切圆 (IC) | 厚度 | 拐角半径 |

|---|---|---|---|

| SCMT 060204 | 6.35mm (0.25") | 1.58mm (0.062") | 0.4mm (0.016") |

| SCMT 09T302 | 9.52mm (0.375") | 3.18mm (0.125") | 0.2mm (0.008") |

| SCMT 09T304 | 9.52mm (0.375") | 3.18mm (0.125") | 0.4mm (0.016") |

| SCMT 09T308 | 9.52mm (0.375") | 3.18mm (0.125") | 0.8mm (0.031") |

| SCMT 120404 | 12.7mm (0.5") | 4.76mm (0.187") | 0.4mm (0.016") |

| SCMT 120408 | 12.7mm (0.5") | 4.76mm (0.187") | 0.8mm (0.031") |

示例:SCMT 09T308

- 正方形

- 0-度间隙角

- 中等耐受性

- 制造商特定的断屑槽和孔配置

- 9.52mm 内切圆直径(约 0.375″ 以英寸来算)

- 3.18毫米厚(约0.125″ 以英寸来算)

- 0.8mm 圆角半径(约 0.031″ 以英寸来算)。

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

硬质合金刀片是目前最通用、最耐用的切削工具之一。但它们是如何制作的呢?是什么让他们如此强大?在本视频中,我们将探索硬质合金刀片背后的科学,从碳化钨的特性到制造工艺。

我们的生产能力