2 刃立铣刀

這是一套 2 支長笛 立铣刀 用於工業端銑應用的切削工具。 雙刃立铣刀用於高速銑削中的優異排屑。這些立铣刀由碳化鎢製成,可耐更多的熱量,同時仍能保持良好的硬度。它們只有兩個切削刃,在加工鋁、中密度纖維板、實木、塑膠和壓克力時具有明顯的優勢。

2 刃立铣刀應用

- 開槽: 在工件上開槽或溝槽。

- 下垂式: 在沒有初步鑽孔操作的情況下切入材料。

- 剖析: 創造複雜的形狀和輪廓

- 加工鋁和其他有色金屬: 由於切屑槽較大,雙刃立铣刀最擅長切削較軟的金屬材料。

- Roughing: 快速移除大量材料,尤其是直徑較小的立铣刀。

2 刃立铣刀特徵

- 兩支長笛 最明顯的特點,提供高效率的排屑並降低切削力。

- 多功能性: 適用於多種材料,尤其是非鐵金屬。

- 強勁的長笛設計: 可有效排出切屑,防止堵塞和熱量堆積。

- 驟降能力: 可直接進入工件,無須預鑽孔

- 良好的表面光潔度: 由於溝槽較少,通常能產生光滑的表面。

- 轉角半徑: 提高工具強度,減少崩角。

- 柄型: 直柄、球鼻或其他選項,適用於特定應用。

- 塗層: AlTiN、TiAlN、TiSiN、TiN、DLC(鑽石塗層)、奈米和鑽石塗層供您選擇,讓您贏得競爭對手。

- 供您控制一切的 HS 編碼參考:8207709000。

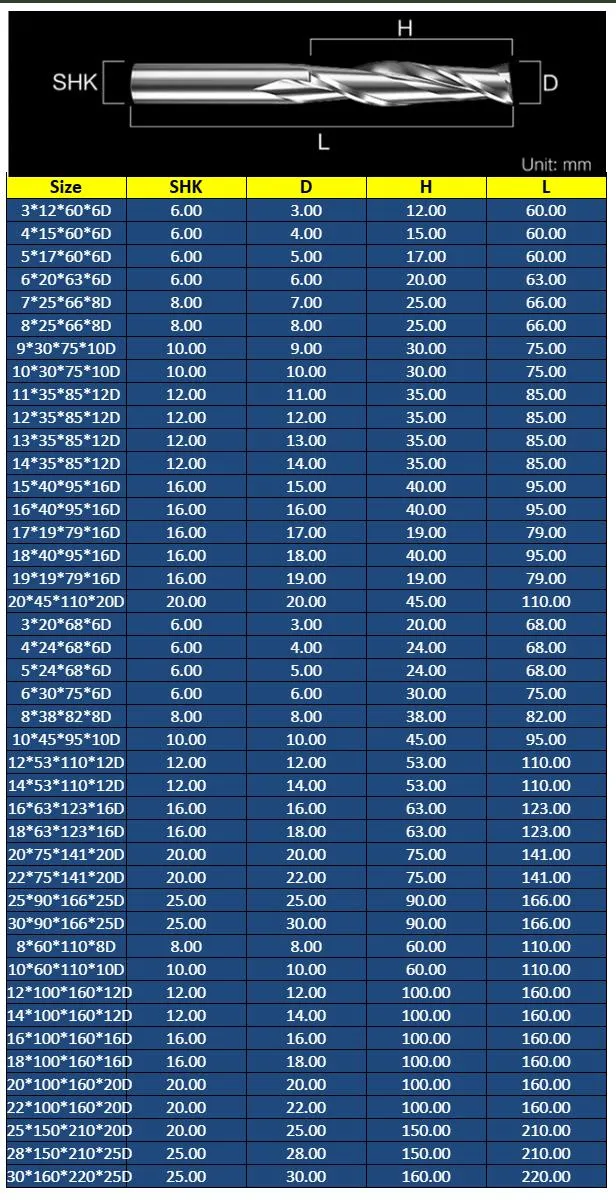

2 刃立铣刀目錄

2 刃立铣刀目錄是為廣泛使用者提供 2 刃立铣刀產品資訊的專業工具。

先進的硬質合金配方

我們使用專有的微粒硬質合金混合物,優化了強度和耐磨性。

創新的幾何圖形

我們已取得專利的刃口設計,可最大限度地排出切屑,並將切削力降至最低。

尖端塗層

我們使用奈米層狀的 PVD 塗層,可增強耐熱性並減少摩擦。

精密研磨

我們的多軸 CNC 研磨機可達到 ±0.0005 英寸的公差。

不要只相信我們的話。以下是我們滿意的客戶所說的話:

我的快樂客戶

我們使用 ONMY TOOLINGS 的單刃立铣刀已經一年多了,效果令人難以置信。我們的刀具壽命增加了 40%,而且表面加工品質無與倫比。我們訂購的客製化單刃滾珠立铣刀改變了我們複雜的 5 軸加工專案。他們工程團隊的支援是一流的"。

莎拉.

精密零件有限公司 CNC 燒錄員

立即取得自訂報價!

P.S. 我們有提供大量訂購折扣嗎?訂購越多,節省越多!

- 無與倫比的原廠直銷價格:省去中間人,與零售價相比,最高可節省 40%。我們高效率的製造過程讓我們能以具競爭力的價格提供優質產品。

- 快速交貨:憑藉精簡的生產流程,我們提供領先業界的交貨時間。您可以在短短 7 天內收到訂製的立銑刀!我們有大量標準尺寸的庫存,可立即出貨。

- 個人化服務:我們的專業工程師團隊隨時準備幫助您找到完美的解決方案,以應對您獨特的加工挑戰。我們提供免費諮詢,分析您的特定需求,並建議理想的刀具規格。

常見問題

- 加工鋁和其他有色金屬: 其較大的切屑槽可有效處理切割這些較軟材料時產生的切屑。

- 開槽: 在工件上開槽或溝槽。

- 下垂式: 在沒有初步鑽孔操作的情況下切入材料。

- 剖析: 創造複雜的形狀和輪廓

- Roughing: 快速移除大量材料,尤其是直徑較小的立铣刀。

雙刃立铣刀是一種具有兩個切削刃或刃口的切削工具。 它是一種多用途工具,用於銑削作業,以移除工件上的材料。

主要特性:

- 兩支長笛 專為高效率排屑和減少熱量堆積而設計。

- 常見應用: 開槽、柱塞和仿形。

是,2 刃立铣刀可以插入

2 刃立铣刀專為處理柱塞加工而設計。 這意味著它們可以直接用於切割工件,而不需要預先鑽孔。

這種能力是它們廣受歡迎的原因之一,特別是在鋁材等材料上,它們的表現更為出色。

雙刃球頭銑刀是一種具有兩個切削刃和球形刀尖的切削工具。 這種獨特的組合使其成為加工曲面、製造弧度和光滑表面的理想選擇。

主要特性:

- 兩支長笛 高效排屑,降低切削力。

- 球形尖端: 可製作圓形輪廓和剖面。

- 應用: 常用於模具製造、原型生產及曲面的一般銑削。

雙刃立铣刀主要用於加工鋁和其他有色金屬。

它的兩個刃口提供了足夠的排屑空間,這對於有效地去除較軟的材料至關重要。

2 刃立铣刀擅長加工較軟的材料和粗加工,4 刃立铣刀則更適合加工較硬的材料和精加工任務。