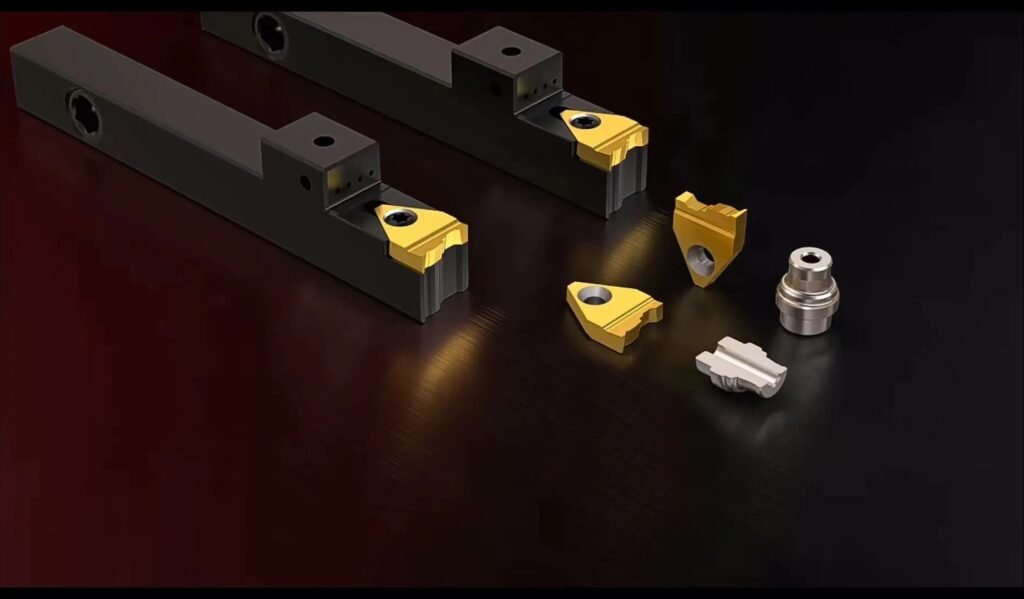

custom carbide inserts

Custom carbide inserts are precision-engineered cutting tools designed for specific machining applications in industries such as automotive, aerospace, and general manufacturing. These inserts are made from tungsten carbide, a highly durable compound known for its exceptional hardness and wear resistance. Manufacturers can tailor the geometry, size, coating, and grade of carbide inserts to meet unique cutting requirements, optimizing performance for particular materials and machining operations. This customization allows for improved cutting efficiency, extended tool life, and enhanced surface finish quality in a wide range of metal cutting processes, including turning, milling, and drilling.

The Power of Precision

Are you ready to take your machining operations to the next level? Discover how custom carbide inserts can transform your productivity, precision, and profitability.

A. The Challenge of Modern Machining

In today's competitive manufacturing landscape, precision, efficiency, and cost-effectiveness are not just goals—they're necessities. As materials become more advanced and tolerances tighter, standard cutting tools often fall short of meeting these demanding requirements.

B. Introducing Custom Carbide Inserts: Your Competitive Edge

Enter the world of custom carbide inserts—a game-changing solution that's revolutionizing the machining industry. These tailored cutting tools are designed to meet your specific needs, offering unparalleled performance and opening new possibilities in manufacturing.

C. Why Standard Tools Fall Short

Off-the-shelf cutting tools are designed for general use, often leading to compromises in performance, tool life, and machining efficiency. In contrast, custom carbide inserts are engineered to excel in your unique applications, providing benefits that standard tools simply can't match.

Unleashing the Potential of Custom Carbide Inserts

A. What Are Custom Carbide Inserts?

Custom carbide inserts are specialized cutting tools tailored to meet specific machining requirements. Unlike standard inserts, these tools are designed with your unique needs in mind, optimizing geometry, material composition, and coating to deliver superior performance in your particular application.

B. The Science Behind Custom Cutting Tools

The power of custom carbide inserts lies in their precisely engineered design:

- Geometry: Cutting edges, chip breakers, and clearance angles are optimized for your specific machining operation.

- Material: Advanced carbide formulations provide the ideal balance of hardness and toughness for your application.

- Coatings: Specialized coatings enhance wear resistance, reduce friction, and improve heat dissipation.

C. Applications Across Industries

Custom carbide inserts are transforming machining operations across various sectors:

- Efficiently machine heat-resistant superalloys

- Achieve tight tolerances on critical components

- Increase productivity in large structural part production

D. Case Study: Productivity Transformed

A leading aerospace manufacturer struggled with tool life and surface finish when machining turbine blades from a nickel-based superalloy. By implementing custom carbide inserts, they achieved:

- 40% increase in tool life

- 25% reduction in cycle time

- Improved surface finish, meeting stringent quality requirements

These results highlight the transformative power of custom cutting tools in addressing specific machining challenges.

- Optimize high-volume production of engine components

- Improve surface finish on precision parts

- Enhance tool life in cast iron machining

- Achieve mirror finishes on implant components

- Efficiently machine difficult materials like titanium and cobalt-chrome

- Maintain strict tolerances for life-critical parts

- Improve tool life in tough downhole component machining

- Enhance performance in corrosion-resistant alloy cutting

- Optimize large-diameter turning operations

- Achieve superior surface finishes in hardened steel

- Improve efficiency in complex 3D milling operations

- Enhance tool life in abrasive material machining

The Advantages That Set You Apart

A. Precision Redefined

Custom carbide inserts take precision to new heights:

- Tighter Tolerances

- Achieve tolerances as tight as ±0.0001 inches consistently

- Maintain dimensional accuracy over longer production runs

- Reduce scrap rates and rework

- Superior Surface Finish

- Attain mirror-like finishes with Ra values as low as 0.1 μm

- Eliminate the need for secondary finishing operations

- Improve part functionality and aesthetics

- Complex Geometries Made Simple

- Machine intricate features with ease

- Reduce the number of operations required

- Achieve consistent results on challenging part designs

B. Efficiency Unleashed

Custom carbide inserts dramatically improve machining efficiency:

- Faster Machining Times

- Increase cutting speeds by up to 50%

- Optimize chip formation for smoother cutting action

- Reduce cycle times and increase throughput

- Reduced Setup and Changeover

- Minimize the number of tool changes required

- Streamline your tooling inventory

- Decrease machine downtime for tool adjustments

- Longer Tool Life

- Extend insert life by 2-3 times compared to standard tools

- Reduce frequency of tool changes

- Lower overall tooling costs

C. Cost-Effectiveness: The Bottom Line

Investing in custom carbide inserts pays dividends:

- Reduced Material Waste

- Optimize material removal rates

- Decrease instances of scrapped parts

- Improve yield from raw material stock

- Energy Savings

- Lower power consumption through optimized cutting action

- Reduce machine run time for each part

- Decrease overall energy costs in your operation

- Decreased Downtime

- Minimize unplanned stoppages due to tool failure

- Reduce time spent on tool changes and adjustments

- Повышение общей эффективности оборудования (OEE)

D. Customization: Your Unique Edge

Tailor your cutting tools to your exact needs:

- Tailored Geometries

- Design cutting edges optimized for your specific operations

- Create custom chip breakers for ideal chip control

- Develop special profiles for unique part features

- Specialized Coatings

- Select coatings that excel in your particular application

- Combine multiple coating layers for optimum performance

- Enhance wear resistance, heat dissipation, and lubricity

- Material Innovations

- Choose from a wide range of carbide grades

- Explore advanced substrates for extreme applications

- Benefit from ongoing research in cutting tool materials

Partner with Us for Cutting-Edge Solutions

A. Our Expertise in Custom Carbide Inserts

Leverage our decades of experience and cutting-edge capabilities:

- State-of-the-Art Design Process

- Advanced CAD/CAM systems for precise insert modeling

- Finite Element Analysis (FEA) for optimized performance

- Virtual machining simulations to predict real-world results

- Cutting-Edge Manufacturing Capabilities

- Latest CNC grinding technology for complex geometries

- Advanced sintering processes for superior material properties

- State-of-the-art coating equipment for enhanced performance

- Rigorous Quality Control

- 100% inspection of critical dimensions

- Automated optical measurement systems

- Extensive testing under simulated machining conditions

B. Collaborative Approach: Your Success is Our Priority

We work hand-in-hand with you to develop the perfect solution:

- Consultation and Needs Assessment

- In-depth analysis of your machining challenges

- Comprehensive review of your current processes

- Identification of key areas for improvement

- Prototype Development and Testing

- Rapid prototyping of custom insert designs

- In-house testing to validate performance

- On-site trials in your actual production environment

- Continuous Optimization

- Ongoing support to fine-tune insert performance

- Regular check-ins to ensure continued satisfaction

- Proactive suggestions for further improvements

C. Success Stories: Real Results from Real Clients

Don’t just take our word for it. Here’s what our clients have achieved:

- Automotive supplier increased tool life by 300% and reduced cycle time by 20%

- Aerospace manufacturer improved surface finish quality by 50% while reducing tooling costs

- Medical device company achieved consistent 0.0005″ tolerances on complex titanium parts

Часто задаваемые вопросы

Common Questions About Custom Carbide Inserts

Typically, 2-4 weeks from initial consultation to prototype delivery.

While the initial cost may be higher, custom inserts often provide significant ROI through improved productivity and longer tool life.

In many cases, yes. We can design inserts with re-sharpening in mind to extend their usable life even further.

We offer a performance guarantee. If the insert doesn’t meet agreed-upon specifications, we’ll refine the design at no additional cost.

If you’re facing challenges with tool life, surface finish, or machining efficiency, custom inserts could likely help. Contact us for a free assessment.

Take the Next Step: Request a Custom Quote

Our team of application engineers is ready to answer any additional questions you may have. Don’t hesitate to reach out for personalized advice on how custom carbide inserts can benefit your specific operation.

Ready to experience the power of custom carbide inserts? Here’s how to get started:

- What Information We Need

- Details about your machining operation (materials, tolerances, volumes)

- Current challenges or limitations you’re facing

- Specific goals you want to achieve

- Our Response Time Guarantee

- Initial response within 24 hours

- Detailed proposal within 5 business days

- Prototype development timeline provided upfront

- No-Obligation Consultation

- Free initial assessment of your needs

- Transparent pricing and ROI projections

- Flexible engagement options to suit your requirements