Your Professional Milling Inserts Manufacturer in China

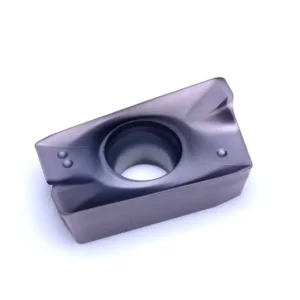

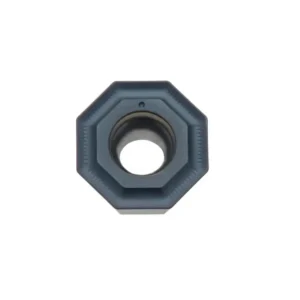

Milling inserts are replaceable and usually indexable cutting tools used in milling machines and machining centers to perform milling operations. They cut away material from a workpiece through movement within the machine or directly from the cutter’s shape. These inserts come in various shapes like square, round, or triangle, allowing for versatility and efficiency in machining a wide range of surfaces and materials. Made typically of materials such as tungsten carbide, milling inserts are known for their hardness and resistance to wear, making them an essential tool in precision metalworking and manufacturing processes.

Check the milling insert Machining Ways

Why us milling inserts?

Milling Insert Variety: Our inventory includes a diverse selection of milling insert types, tailored to meet the specific demands of various machining tasks.

Carbide Insert Milling Cutters Compatibility: Designed to fit a broad range of carbide insert milling cutters, our inserts ensure flexibility and interchangeability across different cutting environments.

Premium Carbide Milling Inserts: Constructed from high-quality materials, our carbide milling inserts are crafted for longevity, maintaining sharpness through extensive use.

Advanced CNC Milling Inserts: Precision-engineered to suit high-tech CNC machining centers, these inserts provide accuracy and speed for complex and detailed milling operations.

Indexable Milling Inserts: We offer easy-to-index milling inserts that minimize downtime by enabling quick and hassle-free replacements on the shop floor.

Milling Carbide Inserts Durability: Every milling carbide insert is treated to resist wear and tear, ensuring consistent performance and reducing the need for frequent replacements.

Cutting Edge Milling Cutter Carbide Inserts: These inserts are made to deliver clean and precise cuts, improving the finish quality and accuracy of machined components.

Round Milling Inserts: Our round milling inserts are perfect for profiling and contouring, providing smooth machining and a perfect finish.

Trusted Milling Inserts Manufacturer: As a reputable manufacturer, we pride ourselves on producing milling inserts that meet strict quality standards and specifications.

Milling Inserts Specification Assurance: We ensure that each insert meets rigorous specification standards for dimensions, tolerances, and material properties, aligning with industry benchmarks.

Carbide Inserts for Milling: Tailored for various milling applications, our carbide inserts offer the hardness and strength needed to cut through materials with ease and precision.

The most cost-efficient and long-lasting milling inserts

Are you still worried about what kind of face milling cutter to choose?

Are you still thinking about exactly what tool to use for better machining of my material?

onmy can recommend the most suitable advice and solutions for any problems you may encounter before and during the machining process. We can vouch for this, as 1000+ customers have proven our reliability.

QUALITY SERVICE, GUARANTEED

In onmy, serving customers well is a cognition that is printed in our bones. Because we believe that serving every customer well can make our business last forever.

We will train our employees’ professional product knowledge from time to time, so that we can face customers more easily, instead of asking three questions.

PROFESSIONAL MACHINES PROVIDE HIGH QUALITY INSERTS

We have 15+ fully automatic grinders, 3 five-axis grinders, and a variety of inspection equipment to provide you with the highest quality milling tools.

In addition, we also have several milling machines. Some people may wonder why we need milling machines. It’s because every new product that comes out of our factory equipment must be tested, not just measured for size and blade data with inspection equipment

This way, we can conduct more comprehensive testing to ensure that the quality and performance of the product meet our requirements.