WNMG 인서트

WNMG insert angle : 0° Negative Rake Insert with double-sided Chipbreaker;

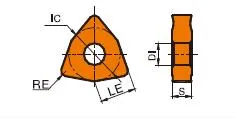

WNMG carbide insert inscribed circle (IC) of 9.525mm/12.7mm, thickness of 3.97mm/4.76mm, and corner (nose) radius of 0.2mm/0.4mm/0.8mm/1.2mm;

Machining Scene:Roughing machining/Semi-finish machining/Finishing machining;

Workpiece materials: Carbon and alloy steel, stainless steel and high temperature alloys, steel and cast iron;

Matching WNMG insert Holder: DWLNR/L, PWLNR/L, PWLNR/L;

WNMG carbide insert sizes:(ISO) WNMG06t304; WNMG06t308; WNMG060404; WNMG060408; WNMG080404; WNMG080408; WNMG080412;

(ANSI) WNMG331/ WNMG332/ WNMG431/ WNMG432;

제품 소개

WNMG Insert can deal with multiple operations by combining different chip breakers and grades.

주요 기능

- 모양: WNMG inserts have a trigon shape (equilateral triangle) with an 80° included angle. This robust shape offers three cutting edges for cost-effectiveness.

- Neutral Rake Angle: The cutting face is neither positive nor negative, but at a 0° angle to the cutting edge. This provides a strong edge suitable for various materials and operations.

- 클리어런스 각도 : Often around 5-7° to prevent the insert rubbing on the workpiece.

- Advanced Chipbreakers: WNMG inserts feature complex chipbreaker geometries on one or both sides, significantly influencing chip formation for specific materials and applications.

- 코팅 : Commonly coated with materials like TiN, TiCN, AlTiN, and others for improved wear resistance and longevity.

WNMG insert Specification

Understanding the WNMG Code

The letters and numbers in the WNMG designation reveal crucial information:

- W: Trigon shape with an 80° included angle

- N: Neutral (0°) rake angle

- 중: Tolerance class (indicates precision of size)

- G: Indicates the specific hole and chipbreaker design (varies by manufacturer)

Numbers:

- Usually the first two numbers represent the inscribed circle (size of the triangle) in sixteenths of an inch (or directly in millimeters for ISO codes).

- The third number represents thickness in sixteenths of an inch.

- The last number often indicates the nose radius (smaller means sharper).

WNMG insert holder

PWLNR/L (KAPR95°)

MWLNR/L (KAPR95°)

Carbide VNMG Insert Dimensions (ISO AND ANSI)

| WNMG INSERT SIZES | ||||

|---|---|---|---|---|

| ISO 지정 | ANSI Designation | 내지 된 원 (IC) | 두께 | 코너 반경 |

| WNMG 060404 | WNMG331 | 6.35mm (0.25") | 3.18mm (0.125") | 0.4mm (0.016") |

| WNMG 060408 | WNMG332 | 6.35mm (0.25") | 3.18mm (0.125") | 0.8mm (0.031") |

| WNMG060412 | WNMG333 | 6.35mm (0.25") | 3.18mm (0.125") | 1.2mm(0.047'') |

| WNMG 080404 | WNMG431 | 8mm (0.315") | 4.76mm (0.187") | 0.4mm (0.016") |

| WNMG 080408 | WNMG432 | 8mm (0.315") | 4.76mm (0.187") | 0.8mm (0.031") |

| WNMG080412 | WNMG433 | 8mm (0.315") | 4.76mm (0.187") | 1.2mm(0.047'') |

Example: WNMG 080408 (ISO)

- Trigon shape, neutral rake insert.

- Inscribed circle of 12.7mm (approx. 1/2″).

- Thickness of 4.76mm (approx. 3/16″).

- Specific chipbreaker/hole design.

자주 묻는 질문

Choose a WNMG insert based on:

- Workpiece Material: Match the insert grade to your material.

- Type of Turning Operation: Roughing needs larger nose radius for strength, finishing needs smaller radius for better surface finish.

- Chip Control: Choosing the perfect chipbreaker geometry is crucial with WNMGs to optimize the cutting process.

중요한 고려 사항

- WNMG inserts are incredibly versatile, but the key to maximizing performance lies in selecting the right chipbreaker for your specific operation and material. Refer to manufacturer documentation for details.

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

카바이드 인서트는 가장 다재다능하고 내구성이 뛰어난 절단 도구 중 하나입니다. 그러나 그들은 어떻게 만들어 졌습니까? 그리고 무엇이 그렇게 강하게 만드는가? 이 비디오에서는 탄산탄의 특성에서 제조 공정에 이르기까지 카바이드 인서트의 과학을 탐구합니다.

우리의 생산 능력

현대식 제조에서 고성능 탄화물 인서트는 필수 도구이며 효율적이고 정확한 금속 가공을위한 기초를 마련합니다. 그러나 이러한 탁월한 인서트는 스스로 존재하지 않습니다. 그들은 고급 기계의 흔들리지 않는 지원으로 지원됩니다.