Your Trusted Carbide Insert Supplier

Premium China Carbide Inserts for Optimal Performance

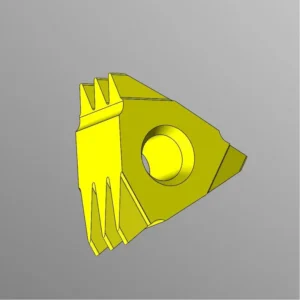

Welcome to ONMY Tools, your go-to source for high-quality carbide inserts. As a leading carbide insert supplier, we specialize in providing premium China carbide inserts that meet the most demanding machining requirements. Our extensive range of products, including top-notch turning inserts, ensures that you’ll find the perfect solution for your manufacturing needs.

Welcome To ONMY Tools

In today’s competitive manufacturing landscape, precision is key to success. Carbide inserts play a crucial role in achieving the highest levels of accuracy and efficiency in machining operations. As an experienced carbide insert supplier, we understand the critical impact these small but mighty components have on your production processes.

Our China carbide inserts are engineered to deliver exceptional performance, durability, and cost-effectiveness. Whether you’re looking for turning inserts, milling inserts, or specialized solutions, we have the expertise and product range to meet your exact specifications.

Why Choose ONMY Carbide Inserts ?

Unparalleled Quality and Precision

At ONMY Tools, we take pride in offering carbide inserts that meet the highest standards of quality and precision. Our inserts are manufactured using advanced techniques and premium materials, ensuring consistent performance and longer tool life. Each insert undergoes rigorous quality control checks to guarantee that it meets our exacting standards before reaching your hands.

Comprehensive Range of Products

As a leading carbide insert supplier, we offer an extensive selection of inserts to cater to various machining applications. From general-purpose turning inserts to specialized milling and drilling inserts, our catalog covers a wide spectrum of shapes, sizes, and grades. This diversity allows you to find the perfect insert for your specific needs, optimizing your machining processes and improving overall productivity.

Cost-Effective Solutions

Our position as a trusted China carbide inserts provider allows us to offer highly competitive pricing without compromising on quality. By choosing us as your turning inserts supplier, you benefit from the cost advantages of Chinese manufacturing combined with stringent quality control measures. This enables you to reduce your tooling costs while maintaining the high standards your production demands.

Industries We Serve

As a trusted carbide insert supplier, we cater to a wide range of industries, including:

Automotive

Providing inserts for engine components, transmission parts, and more

Aerospace

Supplying high-precision inserts for critical aircraft and spacecraft components

Oil and Gas

Offering durable inserts for drilling equipment and pipeline components

General Manufacturing

Supporting diverse machining needs across various sectors

Medical

Delivering precision inserts for the production of medical devices and implants

Die and Mold

Supplying specialized inserts for intricate mold making

The Advantages of Partnering with Us

- Expert Technical Support

Our team of experienced engineers is always ready to assist you in selecting the right carbide inserts for your specific applications. We provide comprehensive technical support, helping you optimize your machining processes and troubleshoot any issues you may encounter.

- Fast and Reliable Delivery

We understand the importance of timely delivery in maintaining your production schedules. As a responsive carbide insert supplier, we maintain a large inventory of standard inserts and offer quick turnaround times for custom orders. Our efficient logistics network ensures that your orders reach you promptly, minimizing downtime and keeping your operations running smoothly.

- Customization Capabilities

Every manufacturing process is unique, and sometimes off-the-shelf solutions aren’t enough. Our in-house research and development team can work with you to design and produce custom carbide inserts that perfectly match your specific requirements. This flexibility allows you to tackle even the most challenging machining tasks with confidence.

- Competitive Pricing

As a China carbide inserts supplier, we leverage the cost advantages of Chinese manufacturing while maintaining strict quality standards. This allows us to offer you highly competitive prices without compromising on the performance and reliability of our products. By choosing us as your turning inserts supplier, you can significantly reduce your tooling costs and improve your bottom line.

Our Commitment to Quality

Quality is at the heart of everything we do at [Company Name]. As a reputable carbide insert supplier, we have implemented rigorous quality control measures throughout our production process. Our manufacturing facilities are equipped with state-of-the-art testing equipment, ensuring that each insert meets our exacting standards before it leaves our premises.

We are proud to hold ISO 9001:2015 certification, demonstrating our commitment to maintaining a robust quality management system. Additionally, our products comply with international standards such as ANSI and DIN, guaranteeing compatibility and performance across various machining systems.

30개 이상의 국가에서 온 행복한 고객

제임스 킹

조안나 폭스

펠리시티 트럼프

Frequently Asked Questions

- Turning Operations: In lathes, carbide inserts are used to remove material from a rotating workpiece to shape and size it. This can include both external and internal turning processes.

- Milling Operations: They are employed in milling machines or machining centers to remove material from a stationary workpiece with a rotating cutting tool.

- Drilling Operations: Carbide inserts are used in drill bits for creating holes in workpieces.

- Boring Operations: They’re instrumental in enlarging and finishing holes that have already been drilled.

- Threading and Tapping: Inserts are designed for cutting threads on the inside (tapping) or outside (thread milling) of a workpiece.

- Parting and Grooving: Specialized carbide inserts are used to create narrow grooves in a workpiece or to cut off parts of material.

- Face Milling Operations: They are applied in face milling tools to generate flat surfaces.

- Gear Cutting: Some inserts are specially designed for cutting gears.

- Finishing Operations: Fine-grained carbide inserts are used for finishing operations where high-quality surface finishes are required.

- Heavy Roughing: Carbide inserts with tough substrates and strong edges are used for heavy roughing applications where high material removal rates are necessary.

1. Material Preparation

2. Powder Mixing

3. Compacting

4. Sintering

5. Post-Sintering Processes

- Trimming: To remove any excess material from the sintering process.

- Grinding: To achieve the precise dimensions, fine finishes, and sharp cutting edges necessary for their application. This process uses diamond grinding wheels due to the extreme hardness of tungsten carbide.

- Coating (Optional): To increase wear resistance and reduce friction, inserts may receive thin coatings of materials such as titanium nitride (TiN), titanium carbonitride (TiCN), or aluminum oxide (Al2O3) through chemical vapor deposition (CVD) or physical vapor deposition (PVD) processes.

- Quality Inspection: Ensuring that the inserts meet all specifications for size, shape, and quality. This may involve visual inspections as well as measurements with precision instruments.

결론

- Identification: First, determine whether your insert can be sharpened. Some inserts have coatings that can be damaged or removed by sharpening.

- Equipment: If you decide to proceed, you’ll need the proper grinding machine with a diamond wheel specifically designed to handle the hardness of carbide.

- Setup: Make sure the grinding wheel is correctly mounted and dressed. The grinder should be set at the correct angle to restore the insert’s cutting geometry.

- Coolant: Use ample coolant to reduce heat build-up, which can lead to micro-fractures and compromise the insert’s integrity.

- Grinding: Carefully and lightly pass the insert against the wheel, following the original geometry and angle. Avoid excessive pressure that can cause chipping.

- Inspection: After sharpening, inspect the insert for any signs of cracking or deformation.

- Cleaning: Clean the insert thoroughly to remove any grinding dust or debris before using it.

1. Powder Preparation

2. Milling

3. Compacting or Pressing

4. Pre-Sintering (Optional)

5. Sintering

6. Post-Sintering Processing

- Grinding: To achieve precise dimensions, specific profiles, and sharp edges.

- Polishing: To enhance surface finish.

- Coating: Many carbide inserts receive one or more thin, hard coatings, such as titanium nitride (TiN), to further improve their performance by reducing wear and friction. Techniques like Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD) are commonly used for coating.

7. Quality Control

Essential Tools:

- A precision grinding machine with a very rigid setup.

- A diamond grinding wheel specifically designed to grind tungsten carbide.

- Coolant system to keep the insert and wheel cool during grinding to prevent thermal damage.

Process:

- Safety First: Always wear safety glasses and follow the machine’s safety recommendations.

- Proper Wheel Selection: Use the correct diamond grinding wheel for the carbide material and consider the bond type, grit size, and concentration.

- Wheel Dressing: Dress the wheel appropriately before starting and periodically during the grinding process to maintain the cutting efficiency of the wheel.

- Insert Mounting: Securely mount the insert to be ground. The setup should prevent any movement or vibration during the grinding process.

- Coolant: Use an appropriate coolant to minimize heat buildup that can damage the carbide or the diamond wheel. The coolant also helps remove ground material from the work area.

- Grinding Angle: Set the correct angle and position for the insert to match the desired edge geometry. This may require specific fixtures or jigs.

- Surface Contact: The wheel should contact the insert at the correct angle, lightly touching the part. Avoid excessive pressure as it might chip the carbide.

- Multiple Passes: Use multiple light passes to achieve the final dimensions or sharpness desired. Taking away too much material at once can damage both the insert and the wheel.

- Constant Inspection: Frequently inspect the insert for the desired finish and geometry and to ensure there are no signs of overheating or cracking. You may use a magnifying tool or microscope for inspection.

- Final Touches: Finish off with a finer grit wheel if necessary to achieve the desired surface finish on the cutting edges.

- Cleaning: Clean the insert thoroughly after grinding to remove any carbide and diamond dust.

1. Shape and Relief Angle

- C for 80° diamond (rhombic)

- D for 55° diamond

- R for round

- S for square

- T for triangle

2. Tolerance and Size

3. Type of Insert Hole (if any) and Cutting Edge Length

4. Chipbreaker Type

5. Material and Coating

6. Manufacturer-Specific Coding

How to Identify When Unsure:

- Manufacturer’s Catalog: Many manufacturers provide detailed catalogs (often online) that explain their coding systems and allow you to match specific codes to insert types.

- Manufacturer’s Website or Support: Visiting the manufacturer’s website or contacting their support team can provide direct information about an insert.

- Comparison: Visually compare the insert against known samples or images from catalogs. This can help with identifying shape, size, and potentially even material or coating based on color and finish.

- IC (Inscribed Circle Size): This is applicable to inserts that are round, triangular, square, etc. It’s the diameter of the largest circle that can fit within the insert’s edges.

- Thickness (T): The distance from the bottom to the top surface of the insert.

- Nose Radius (R): If the insert has a rounded cutting point, this is the radius of that curve, which affects the finish of the cut.

- Length (L) and Width (W): For rectangular inserts, these are the lengths of the sides. For others, it may refer to the distance from corner to corner.

- Corner Angle: The angle of the cutting corners for inserts that are not round.

How to Measure These Dimensions:

Using Calipers:

- IC: Place the calipers across the insert to measure the inscribed circle.

- Thickness: Close the caliper’s jaws over the thickest part of the insert, which is typically the center.

- Nose Radius: Use the calipers or a radius gauge to measure the curve at the tip of the insert.

- Length & Width: Place the calipers along the edges to measure the length and width.

Using Micrometers:

- Thickness: Use an outside micrometer to measure from the bottom to the top of the insert.

- Length, Width & IC: Measure between appropriate faces to get the length or width. For inscribed circle size, measure across the insert diagonally.

Using Manufacturer’s Specifications:

Specialty Tools:

Optical Comparators and CMMs:

Other Considerations:

- Edge Wear: Measure the dimensions in a few places to account for potential edge wear.

- Safety: Ensure that you handle the inserts carefully, particularly if they have sharp edges.

Carbide inserts are replaceable and usually indexable bits of cemented carbide used in machining steels, cast iron, high-temperature alloys, and nonferrous materials. They serve as one of the most critical components in many types of industrial tools and machinery.

Carbide inserts are used in manufacturing because they can withstand higher temperatures than high speed steel, providing an extended cutting life. They are designed to provide faster machining and withstand interrupted cuts.

Here are some key characteristics and uses of carbide inserts:

Material: They are typically made from tungsten carbide, a very tough material that can withstand high temperatures and is highly resistant to wear. This allows the inserts to maintain a sharp cutting edge even when machining tough materials.

Design: Most carbide inserts are indexable, meaning they have more than one cutting edge. When one edge wears out, the insert can be turned around to use another edge. This design can significantly increase the life of a single insert.

Application: Carbide inserts are widely used in cutting tools for the metalworking industry, in lathes, milling machines, and CNC machines. They can handle a wide range of machining tasks, including turning, boring, threading, and grooving.

Varieties: They come in various shapes (e.g., round, square, triangle) to suit different kinds of cutting tasks. They may also come with various coatings that can further extend their life and improve their performance.

Accessibility: They are replaceable. Once the cutting edges of a carbide insert are worn or damaged, instead of discarding the entire tool, you can just replace the insert.

Production Efficiency: Carbide inserts offer improved production rates, better finishes on parts, and they can hold size with better accuracy.

Note that while carbide is a hard material and can handle various machining tasks effectively, it’s also quite brittle. Therefore, carbide inserts might not be the best choice for applications with high mechanical shock or vibration.

- For Triangle Inserts: The IC is the diameter of the largest circle that fits within the three points (corners) of the triangle.

- For Square or Rhombic Inserts: The IC is determined by the largest circle that fits within the four points of the square or rhombus, effectively touching the midpoints of each side.

- For Round Inserts: The IC corresponds to the diameter of the insert itself since a circle’s boundary fits perfectly around itself.

- Tool Holder Compatibility: It helps in determining which inserts fit into specific tool holders or bore sizes.

- Performance Considerations: The size of the IC can also impact the performance of the insert in terms of cutting forces and stability.

- Standardization: It provides a standardized measure to discuss and compare inserts, facilitating easier identification and selection for specific applications.

- Material to be Machined: The type of material you’re cutting greatly influences the choice of insert. For example, hardened steels may require a harder and more wear-resistant grade of carbide, whereas softer materials could benefit from a tougher insert that can withstand chip deformation without breaking.

- Type of Operation: Different operations such as turning, milling, drilling, boring, or threading each have specific insert requirements. For instance, roughing operations might require an insert with a tougher grade and a larger nose radius, while finishing operations might need a harder grade with a sharp cutting edge and a smaller nose radius.

- Machining Conditions: This includes cutting speed, feed rate, depth of cut, and coolant availability. Higher cutting speeds and deeper cuts often require harder, more wear-resistant carbide grades.

- Insert Shape: The shape of the insert should match the requirements of your specific application. For instance, round inserts provide the strongest cutting edge and are preferred for high-feed milling operations, while square or rhombic inserts provide more edges and are versatile across different operations.

- Insert Size: The size of the insert (usually described by the inscribed circle diameter) needs to be compatible with your tool holder and should match the scale of your operation.

- Insert Grade: The carbide grade should be chosen based on the material and the type of operation. A P-grade is often used for steel, M-grade for stainless steel, and K-grade for cast iron. Harder grades are generally more wear-resistant, while tougher grades can withstand more shock and vibration.

- Coating Material: Coated carbide inserts can provide increased hardness, heat resistance, and longer tool life. However, the choice of coating will depend on the workpiece material and the machining conditions.

- Chipbreaker Style: The style of the chipbreaker will depend on the material and type of operation. A chipbreaker helps in controlling the chip flow and direction. Some are designed for finishing operations while others are designed for roughing operations.

Characteristics:

- Hardness and Wear Resistance: Carbide is significantly harder than the materials it cuts, providing excellent wear resistance and the ability to maintain a sharp cutting edge at high temperatures.

- Material Specificity: Different grades of carbide are formulated to optimize performance across a range of materials, including steel, stainless steel, cast iron, non-ferrous metals, and exotic alloys.

- Shape and Size: Common shapes include triangular, square, rhombic, and round, each offering different angles and numbers of cutting edges. The inscribed circle (IC) diameter is a key dimension that describes the size of the insert.

- Coating: Many carbide inserts are coated with materials like Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Aluminum Oxide (Al2O3) to enhance hardness, wear resistance, and reduce friction.

Uses:

- External Turning: Shaping the external surface of the workpiece, including straight, tapered, and contoured sections.

- Internal Turning (Boring): Enlarging and finishing holes or machining the inner surface of hollow workpieces.

- Facing: Cutting a flat surface perpendicular to the workpiece’s rotational axis.

- Thread Cutting: Producing internal or external threads.

- Grooving and Parting: Cutting narrow grooves or separating a part from the rest of the workpiece.

Selection Factors:

- The material of the workpiece: Different materials require different carbide grades and coatings.

- The type of turning operation: Specific shapes and edge preparations optimize performance in roughing, finishing, and other operations.

- Machining conditions: Cutting speed, feed rate, and depth of cut influence the grade and geometry of the insert.

- Tool holder compatibility: The insert must fit the holder used on the machine.

1. Shape

- C (80° Diamond)

- D (55° Diamond)

- R (Round)

- S (Square)

- T (Triangle)

- V (35° Diamond)

2. Relief Angle

- N (0°)

- A (3°)

- B (5°)

- C (7°)

- D (15°)

- E (20°)

- F (25°)

- G (30°)

3. Tolerance & Insert Type

4. Size

5. Thickness

6. Cutting Edge Length or Shape

7. Nose Radius

8. Chipbreaker Type

9. Insert Grade

Our Ordering Process

Ordering from ONMY Tools is simple and straightforward:

- Browse our online catalog or contact our sales team for product information.

- Select the desired carbide inserts or request a custom quote.

- Provide your specific requirements and quantity needed.

- Review and confirm your order details.

- Choose your preferred payment method and complete the transaction.

- Receive order confirmation and estimated delivery date.

- Track your shipment and prepare for arrival.

For large or recurring orders, we offer streamlined processes and potential volume discounts. Contact our sales team to discuss your specific needs.

Your Reliable Turning Inserts Supplier

Ready to experience the difference of working with a top-tier carbide insert supplier? We’re here to assist you