SCGX 인서트

SCGX insert angle: 90° Square ,7° Positive Rake Insert with single-sided Chipbreaker;

스크류 온 삽입물;

High Polish Square Turning Insert for Aluminum Applications;

사각형 탄화물 삽입;

차단기 응용 프로그램 : 반제품 & 마무리 가공;

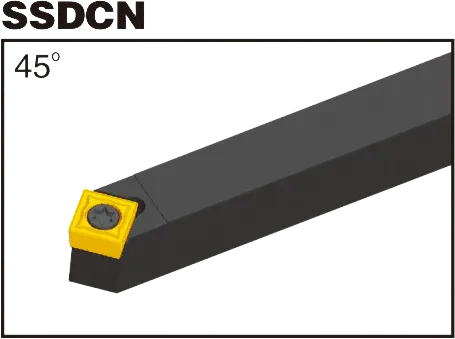

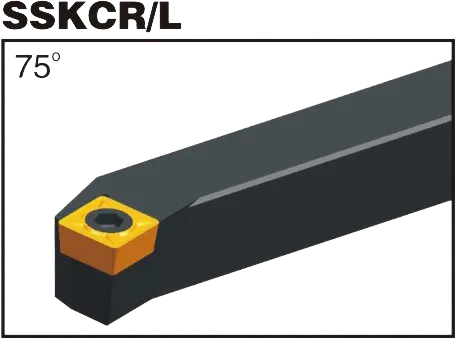

일치하는 TurningTool Holder : SSDCN, SSKCR/L;

SCGX Insert can deal with multiple operations by combining different chip breakers and grades;

재료 : 텅스텐 카바이드;

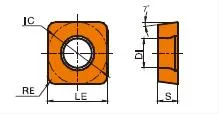

SCGX insert specification

SCGX insert is the specialist in external turning. The function of a chip breaker is to improve chip control and to reduce cutting resistance.

A better balance between the two will increase the machining performance.

If chips can be broken into suitable lengths by the chip breaker, they will not wrap around the workpiece, vibration will decrease and tools will not be so easily damaged.

Chip breakers also affect cutting resistance.

Reduced cutting resistance can avoid chipping and fracturing of the cutting edge caused by vibration.

Additionally, lower cutting resistance can decrease the load and heat, and can delay the development of tool wear.

SCGX insert Meaning

Understanding the SCGX Insert Code

- 에스: 모양 : 사각형

- 기음: Clearance Angle: 7 degrees (positive)

- G: 공차 : 중간 공차는 표준이지만 다른 정밀 공차를 사용할 수 있습니다.

- X: 칩 브레이커 스타일 & Hole Configuration. This letter designates the specific chipbreaker geometry and whether the insert has a hole or not.

- 숫자 숫자 :

- 처음 두 자리 : 밀리미터로 된 원형 (IC) 직경. 대략적인 인치 등가를 얻으려면이 숫자를 25.4로 나눕니다.

- 다음 두 자리 : 밀리미터의 두께. 인치로 전환하려면 25.4로 나눕니다.

- 마지막 두 자리 : 밀리미터의 코너 반경. 인치로 변환하려면 25.4로 나눕니다.

SCGX insert holder

SCGX Insert Dimensions (ISO)

| ISO 지정 | 내지 된 원 (IC) | 두께 | 코너 반경 |

|---|---|---|---|

| SCGX 09T302 | 9.52mm (0.375") | 3.18mm (0.125") | 0.2mm (0.008") |

| SCGX 09T304 | 9.52mm (0.375") | 3.18mm (0.125") | 0.4mm (0.016") |

| SCGX 09T308 | 9.52mm (0.375") | 3.18mm (0.125") | 0.8mm (0.031") |

| SCGX 120404 | 12.7mm (0.5") | 4.76mm (0.187") | 0.4mm (0.016") |

| SCGX 120408 | 12.7mm (0.5") | 4.76mm (0.187") | 0.8mm (0.031") |

Example: SCGX 09T308

- 정사각형 모양

- 7도 양의 클리어런스 각도

- 중간 공차

- 제조업체 별 칩 브레이커 및 홀 구성

- 9.52mm 내장 직경 (약 0.375)″ 인치)

- 두께 3.18mm (약 0.125″ 인치)

- 0.8mm 코너 반경 (약 0.031″ 인치).

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

카바이드 인서트는 가장 다재다능하고 내구성이 뛰어난 절단 도구 중 하나입니다. 그러나 그들은 어떻게 만들어 졌습니까? 그리고 무엇이 그렇게 강하게 만드는가? 이 비디오에서는 탄산탄의 특성에서 제조 공정에 이르기까지 카바이드 인서트의 과학을 탐구합니다.

우리의 생산 능력