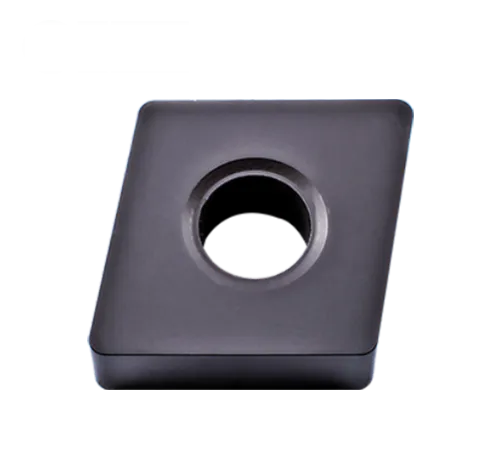

CNMA 인서트

CNMA insert angle:0° Negative rake insert and no chipbreaker;

80° rhombic turning insert;

Primary workpiece material: Hard material; cast Iron; steel;

Primary workpiece material code: P; H; K

Insert holding method: Pin; Clamp;

Breaker application: Roughing, semi-finishing, finishing;

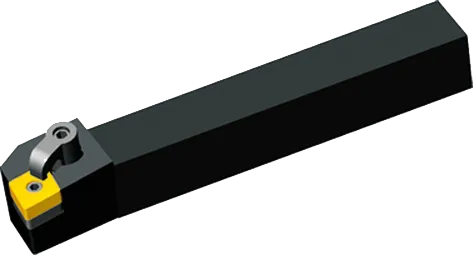

Matching cnma insert tool holder: PCBNR/L, PCLNR/L, MCLNR/L,MCBNR/L;

Grade: Both PVD and CVD;

Material : Tungsten Carbide;

CNMA insert tool holder

MCLNR/L

CNMA insert Introduction:

CNMA Carbide Inserts: The Essentials

- 모양: Rhombic (diamond) with an 80-degree included angle.

- 클리어런스 각도 : 0 degrees

- Cutting Edges: Double-sided, offering two cutting edges per insert for cost-effectiveness.

- Chipbreaker Geometries: Diverse range of chipbreaker styles from various manufacturers are available. These are tailored to specific materials and machining operations (roughing, finishing, etc.).

- Key Uses: Primarily used for general turning operations and some facing work on a range of materials.

Common Materials CNMA Inserts are Used For

- Cast Iron: Suitable for many cast iron applications.

Advantages of CNMA Inserts

- Cost-effective: Due to their double-sided design, offering longer tool life per insert.

- Versatile: The range of grades and chipbreakers make them suitable for many machining applications.

- Strong Geometric Shape: The 80-degree diamond shape provides strength and rigidity for their size.

Important Considerations

- Match the Grade to Your Material: Choosing the right insert coating and substrate composition is crucial for optimal tool life and performance in the specific material you’re cutting.

- Select the Right Chipbreaker: The chipbreaker geometry significantly influences how chips are formed and broken. It should be chosen based on the material and type of machining operation.

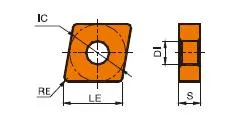

CNMA Insert Dimensions (ISO)

| TYPE | CNMA INSERT DIAMENTIONS(mm) | ||||

|---|---|---|---|---|---|

| LE | IC | 에스 | DI | 답장 | |

| CNMA120404 | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 |

| CNMA120408 | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

| CNMA120412 | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 |

| CNMA120416 | 12.9 | 12.7 | 4.76 | 5.16 | 1.6 |

| CNMA160608 | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 |

| CNMA160612 | 16.1 | 15.875 | 6.35 | 6.35 | 1.2 |

| CNMA160616 | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 |

| CNMA190612 | 19.3 | 19.05 | 6.35 | 7.94 | 1.2 |

| CNMA190616 | 19.3 | 19.05 | 6.35 | 7.94 | 1.6 |

Example: CNMA 120408

- 12: Inscribed Circle (IC) of 12.7mm (approx. 0.5 inches)

- 04: Thickness of 4.76mm (approx. 0.187 inches)

- 08: Corner radius of 0.8mm (approx. 0.031 inches)

Key Dimensions

Inscribed Circle (IC): The diameter of the largest circle that fits within the insert. Common IC sizes include:

- 12.7mm (0.5″)

- 16mm (0.63″)

- 19.05mm (0.75″)

두께: Impacts insert strength and the number of usable cutting edges. Common thicknesses include:

- 3.18mm (0.125″)

- 4.76mm (0.187″)

- 6.35mm (0.25″)

Corner Radius: Affects surface finish and strength at the cutting edge. Common sizes include:

- 0.4mm (0.016″)

- 0.8mm (0.031″)

- 1.2mm (0.047″)

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

카바이드 인서트는 가장 다재다능하고 내구성이 뛰어난 절단 도구 중 하나입니다. 그러나 그들은 어떻게 만들어 졌습니까? 그리고 무엇이 그렇게 강하게 만드는가? 이 비디오에서는 탄산탄의 특성에서 제조 공정에 이르기까지 카바이드 인서트의 과학을 탐구합니다.

우리의 생산 능력