CNMG vs WNMG Inserts: A Comparison

When evaluating cnmg vs wnmg inserts for CNC turning, the core difference lies in the trade-off between structural stability and operational convenience. The cnmg insert is the industry standard for maximum stability and heavy-duty versatility. Its diamond shape offers a massive contact area with the tool holder, making it superior for roughing and interrupted cuts. The wnmg turning insert, with its trigon shape, is the champion of production efficiency. It offers 6 usable 80° cutting edges on a single holder (compared to the standard 4 on a CNMG), making it ideal for high-volume manufacturing where reducing tool cost is the primary goal.

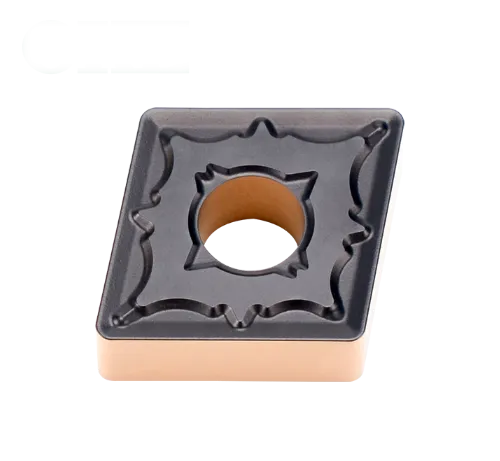

1. What is CNMG Insert? (Geometry & The 8-Edge Secret)

To understand the comparison, we must first answer: what is cnmg insert?

The cnmg insert is a negative-rake, double-sided, rhombic (diamond-shaped) insert. The ISO code “C” denotes its 80° diamond shape. Because it is a “Negative” insert (denoted by the letter ‘N’), the cnmg insert clearance angle is 0°. This geometry requires the insert to be tilted in the holder to create clearance, but it allows the insert to be double-sided, doubling the lifespan compared to positive inserts.

The “4 vs. 8 Edge” Reality

- Standard Use (4 Edges): Using a standard cnmg insert holder (like a PCLNR/L), you use the two 80° corners on the top and two on the bottom.

- Advanced Use (8 Edges): The CNMG geometry actually possesses 8 cutting edges. The four “hidden” edges are the 100° obtuse corners. By switching to a 75° lead angle holder (like an MCKNR), you can utilize these 100° corners for facing operations or heavy scale removal, maximizing the insert’s value.

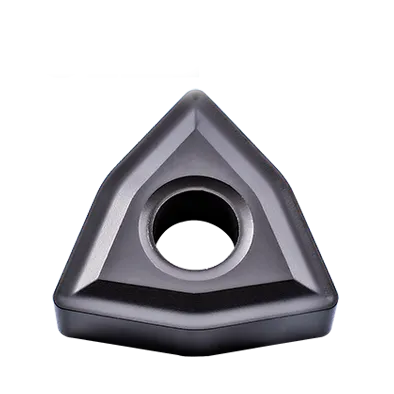

2. What is WNMG? (The High-Volume Specialist)

The wnmg turning insert features a “Trigon” shape (ISO code “W”). Like the CNMG, it utilizes an 80° nose angle, meaning it can perform almost identical turning and facing operations.

The distinct advantage of the WNMG is its six identical 80° corners (3 on top, 3 on bottom). Unlike the CNMG, which requires changing holders to use all 8 corners, the WNMG allows you to use all 6 corners using a single wnmg insert tool holder (typically an MWLNR/L).

For example, a common specification like the lathe insert wnmg 080404 (Size 08, Thickness 04, Radius 04) is a staple in mass production environments because it offers 50% more cutting edges per insert than a CNMG used in a standard setup.

3. Direct Comparison: CNMG vs WNMG

The following table breaks down the technical and economic differences between these two popular inserts.

| Feature | CNMG Insert | WNMG Insert |

| Shape Geometry | Rhombic (Diamond) | Trigon (Distorted Triangle) |

| Nose Angle | 80° | 80° |

| Usable Edges (Standard Holder) | 4 Edges (80° corners only) | 6 Edges (All 80° corners) |

| Max Potential Edges | 8 Edges (Requires standard + special 100° holder) | 6 Edges (All accessible with one holder) |

| Holder Contact Area | High. Long straight edge provides maximum stability. | Medium. Shorter locating edge than CNMG. |

| Rigidity | Excellent. Best for heavy roughing & interrupted cuts. | Good. Sufficient for general turning, but less rigid than CNMG. |

| Tool Holder Management | Complex. Needs PCLNR (turning) + MCKNR (facing) to use all edges. | Simple. One wnmg insert tool holder (MWLNR) uses all edges. |

| Common Application | General purpose, Job Shops, Heavy Duty. | High-volume production lines (Automotive/Aerospace). |

| Typical Sizes | cnmg insert sizes range from 0903xx to massive 1906xx. | Common sizes include 0604xx and lathe insert wnmg 080404. |

4. The Verdict: Which One Should You Choose?

Your choice depends entirely on your production environment and machine rigidity.

Choose CNMG If:

- You are a Job Shop handling diverse materials and uncertain casting conditions.

- You need maximum rigidity for heavy cuts (Depth of Cut > 3-4mm).

- You are willing to invest in a secondary cnmg insert holder (MCKNR/L) to utilize the “hidden” 100° corners for facing operations, achieving the lowest possible cost per edge.

Choose WNMG If:

- You are a Production Facility running thousands of identical steel parts.

- You want “Plug and Play” simplicity: One holder, six edges, no thinking required.

- You are performing continuous cutting where extreme rigidity is not the primary bottleneck.

Pro Tip: If you have a drawer full of used CNMG inserts, buy an MCKNR holder today. You can reuse the “dead” inserts to rough face parts using the unused 100° corners.