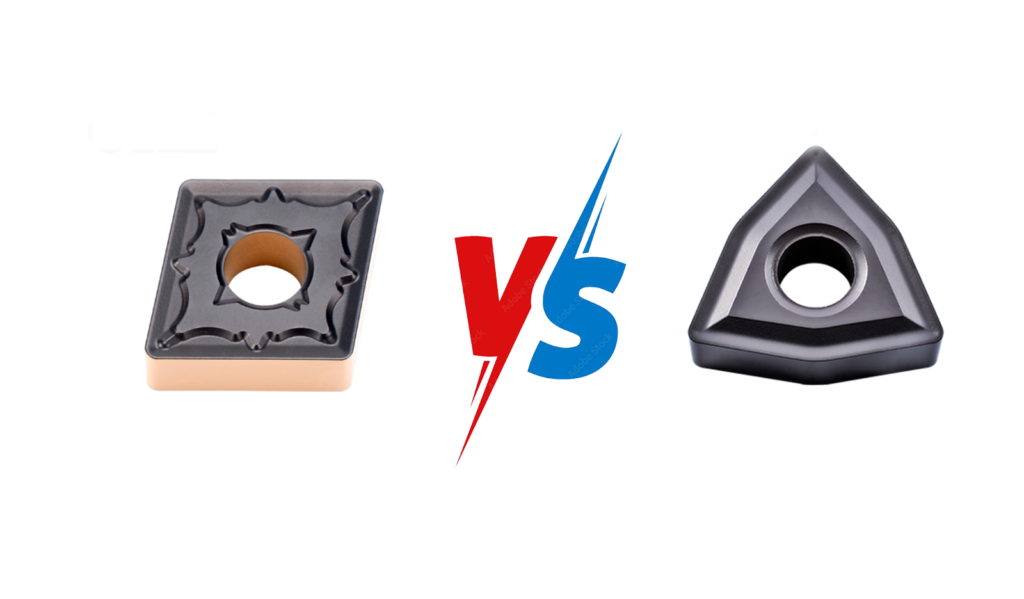

CNMG vs WNMG 是轉向操作中使用的兩種常見類型的插入物。儘管它們具有相似之處,但它們也具有不同的特徵,使其適合不同的應用程序。

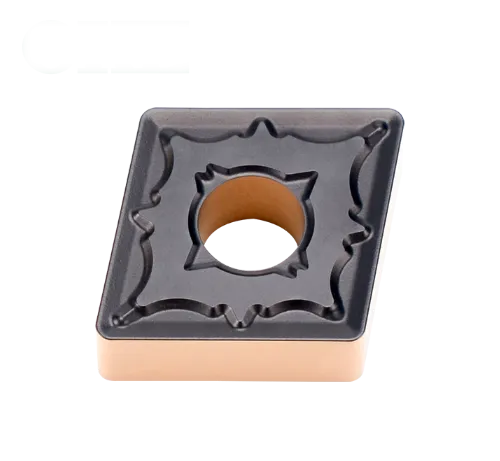

CNMG插入

- 形狀:CNMG插入物具有80°切角的鑽石形狀。

- 多功能性:它們是通用的,可用於轉彎和麵對操作。

- 力量:CNMG插入物以其邊緣強度而聞名,使其適合重型切割和粗糙應用。

- 應用領域:非常適合在同一工具中進行工作店工作或粗暴轉彎和麵對面。

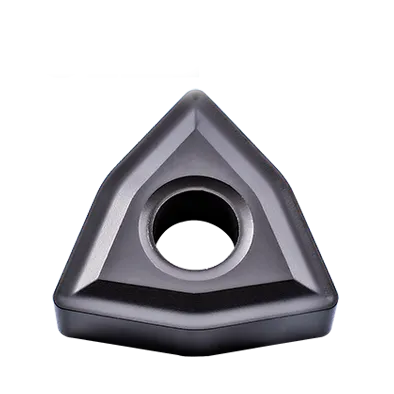

WNMG插入

- 形狀:WNMG插入物具有80°切角的三角形形狀,但它們提供了六個切割邊緣。

- 經濟:與CNMG插入物相比,它們提供了兩個額外的角落,這可能更經濟。

- 力量:與CNMG插入物相比,對於粗糙應用,WNMG插入物通常不太強。

- 應用領域:適用於一般的轉彎和麵對工作,尤其是在不需要大量切割的情況下。

關鍵差異

- 邊緣強度:CNMG插入物具有更好的邊緣強度,使其更適合粗糙。

- 切割邊緣:WNMG插入物提供了更多的切割邊緣,這可能更經濟,但可能缺乏重型切割的力量。

- 工具固定器磨損:WNMG刀具支架對插入物的軸承表面較小,從而使它們更容易隨著時間的流逝而磨損。