Вставка РПМТ

Вы ищете режущие инструменты, которые обеспечивают непревзойденную точность, долговечность и универсальность? Вставки RPMT разработаны для соответствия самым высоким стандартам в обработке, предлагая исключительные характеристики в различных приложениях. Узнайте, как вставки RPMT могут преобразовать ваши производственные процессы и привести к превосходным результатам.

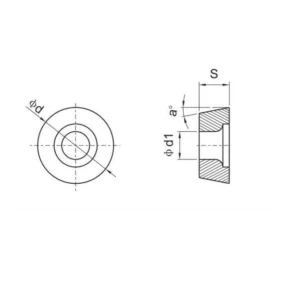

- р: Указывает форму вставки, обычно круглую в случае вставки RPMT.

- П: Определяет класс толерантности вставки.

- М: Относится к методу зажима или стилю Chip Breaker.

- Т: Представляет толщину вставки или конкретные функции, связанные с дизайном.

Почему RPMT - идеальный выбор для вашего бизнеса

Исключительная точность и точность

Вставки RPMT разработаны с расширенной геометрией, чтобы обеспечить точную резку и высокую точность в ваших операциях обработки. Их дизайн гарантирует, что вы достигаете точных спецификаций и жестких допусков, необходимых для высококачественных результатов.

Преимущества:

- Достичь точных сокращений и подробных результатов.

- Уменьшите необходимость в переработке и исправлениях.

Превосходная долговечность и долговечность

Построенные из высококачественного карбида или Cermet и оснащенных передовыми покрытиями, вставки RPMT создаются для выдержания требовательных условий. Их долговечность приводит к более длительному сроку службы инструмента и меньшим количеством изменений вставки.

Преимущества:

- Выдержать высокие силы резки и температуры.

- Минимизировать замену инструмента и связанное время простоя.

Универсальные приложения

Вставки RPMT универсальны и подходят для широкого спектра задач обработки, в том числе:

- Токарные операции: Идеально идеально подходит как для процессов черновой, так и для отделки.

- Фрезерные операции: Эффективно для фрезерования, прорезь и профилирования.

- Канавка и разделение: Подходит для внутреннего и внешнего канавки, а также разделение операций.

Преимущества:

- Адаптируется к различным материалам и условиям резки.

- Опропит инвентаризацию инструмента, обрабатывая несколько приложений.

Расширенные покрытия и материалы

Вставки RPMT поставляются с высококлассными покрытиями, такими как PVD (физическое осаждение пара) и сердечно-сосудистые заболевания (химическое осаждение паров), которые повышают устойчивость к износу и производительность резки. Эти покрытия помогают уменьшить трение и повысить эффективность инструмента.

Преимущества:

- Улучшить долговечность инструмента и производительность.

- Обеспечить постоянные результаты в различных средах обработки.

Выбор правильной вставки RPMT

Чтобы выбрать соответствующую вставку RPMT для вашего приложения, рассмотрите:

- Материал: Тип обработанного материала (например, сталь, нержавеющая сталь, чугун).

- Тип работы: Конкретная операция обработки (например, поворот, фрезерование, канавка).

- Условия резки: Такие факторы, как скорость резки, скорость подачи и глубина разреза.

- Вставьте геометрию и покрытие: Выберите на основе необходимой производительности и потребностей приложения.

Наши производственные возможности