APKT-вставка

APKT insert are versatile cutting tools widely used in industrial milling operations. These inserts play a crucial role in various machining processes, offering efficiency and precision across different materials and applications.

APKT Insert Specification:

- АПКТ is a specific designation for a type of insert shape and geometry.

- А stands for the insert shape, which is typically a parallelogram or rectangular shape with specific relief angles.

- P refers to the tolerance class of the insert.

- K designates the chipbreaker style, which affects how chips are formed and evacuated during the cutting process.

- Т often indicates the insert thickness or a specific feature related to the insert’s design.

Key Features of APKT Inserts

- Geometry: APKT inserts have a triangular shape with a positive rake angle, designed for optimal cutting performance.

- APKT Insert Sizes: The most common sizes include:

- APKT 1604: A versatile size suitable for many applications

- APKT 1003: A smaller option ideal for more precise milling tasks

- Material Compatibility:

- APKT 1604 inserts for steel: Engineered to withstand the rigors of milling ferrous materials

- APKT insert for aluminum: Designed with specific geometries to prevent built-up edge and ensure smooth chip evacuation.

- Versatility: APKT inserts can be used for face milling, shoulder milling, and other cutting operations across various industries.

- Indexability: Each insert typically has three cutting edges, allowing for multiple uses before replacement.

- Material Composition: Usually made from carbide, often with specialized coatings to enhance performance and longevity.

- APKT Insert Sizes and Applications:

- APKT 1604: Commonly used for general-purpose milling in medium to large-scale operations

- APKT 1003: Preferred for smaller milling cutters or when working with tighter tolerances

- Performance Characteristics:

- Positive rake angle reduces cutting forces

- Chip breaker design for improved chip control

- Available in various grades to match specific machining requirements

- Industry Usage: Widely adopted in automotive manufacturing, aerospace, general metalworking, and tool and die making.

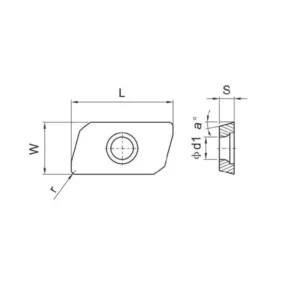

APKT Insert Dimensions (ISO)

Key Dimensional Aspects:

APKT 1604 Dimensions:

- Вписанный круг (IC): 9,525 мм

- Thickness (S): 4.76 mm

- Corner Radius (R): 0.8 mm

- Cutting Edge Length (L): 16.0 mm

APKT 1003 Dimensions:

- Inscribed Circle (IC): 6.0 mm

- Thickness (S): 3.18 mm

- Corner Radius (R): 0.4 mm

- Cutting Edge Length (L): 10.0 mm

- APKT Insert Sizes: The first two digits in the insert designation (e.g., 16 in APKT 1604) represent the cutting edge length in millimeters.

- APKT Insert Specification: The last two digits (e.g., 04 in APKT 1604) indicate the insert thickness in millimeters divided by 10.

- Corner Radius: Available in various options to suit different finishing requirements.

Choosing the Right Insert:

When selecting between APKT 1604, APKT 1003, or other sizes, consider:

- The size of your milling cutter

- The material you’re machining (e.g., steel vs. aluminum)

- The required depth of cut and feed rates

- Требования к отделке поверхности

Our range of APKT insert sizes caters to various industrial milling needs. Whether you require APKT 1604 inserts for steel applications or specialized APKT inserts for aluminum, our wholesale catalog has options to optimize your machining processes.

For detailed specifications or to discuss which APKT insert dimensions best suit your large-scale operations, please contact our technical sales team.

Наши производственные возможности