Carbide Rods: A Comprehensive Technical Analysis from Material Science to Advanced Applications

Introduction

Cemented carbide is not a single material but a class of composite materials with tunable properties. The core concept involves using a hard refractory metal carbide phase (such as tungsten carbide) as a skeleton, which is then “cemented” together by a more ductile metallic binder (such as cobalt), creating an engineering material that possesses both extremely high hardness and sufficient toughness. Within this material system, carbide rods are the most primary and fundamental semi-finished form, serving as the starting point for manufacturing a wide range of high-performance precision tools.

The history of cemented carbide dates back to 1923 in Germany, where the invention of the first tungsten carbide-cobalt alloy, with a hardness second only to diamond, marked the beginning of a new era. However, this early alloy performed poorly when cutting steel. It was not until 1929 that this problem was solved by adding other carbides, such as titanium carbide, to the composition, which greatly expanded its range of applications. This development revolutionized modern manufacturing, enabling machining speeds to increase by hundreds or even thousands of times and allowing for the efficient cutting of various difficult-to-machine materials. Consequently, it replaced traditional high-speed steel (HSS) and carbon tool steel in many fields.

This report aims to provide an in-depth, interdisciplinary analysis of carbide rods, covering their fundamental material science, core manufacturing processes, classification and standardization systems, key industrial applications, and cutting-edge trends in future technological development. It is intended for engineers, material scientists, and technical personnel in related industries, striving to offer a comprehensive and thorough technical reference.

Section 1: The Material Science of Cemented Carbide

1.1 Core Components: Hard Phase and Binder Phase

The macroscopic properties of cemented carbide are determined by its microscopic two-phase structure: a hard-phase skeleton that provides hardness and a metallic binder-phase matrix that provides toughness.

Tungsten Carbide (WC) Skeleton (α-phase)

Tungsten carbide is the most critical component of cemented carbide, typically accounting for 70% to 97% of the total weight. It imparts the material’s defining physical characteristics: extremely high hardness (Mohs hardness of about 9-9.5, second only to diamond), a high melting point of over 2000°C, and exceptional wear resistance. During the manufacturing process, the grain size of the tungsten carbide powder is a key control variable, with sizes ranging from sub-micron (0.2–0.5 µm) and fine grain (0.5–0.8 µm) to coarser particles (up to 10 µm).

Cobalt (Co) Binder (β-phase)

Cobalt is the most widely used binder metal, with its content typically ranging from 3% to 27%. It acts like cement, tightly binding the hard but brittle tungsten carbide particles together. Cobalt’s primary role is to provide the necessary toughness (resistance to fracture) and transverse rupture strength to the material. During the subsequent sintering process, cobalt melts into a liquid phase, thoroughly wetting and enveloping the tungsten carbide particles. Upon cooling, it forms a continuous metallic matrix, creating a dense composite material structure.

The Hardness-Toughness Paradigm

The relationship between hardness and toughness is the central principle in designing cemented carbide grades. There is a controllable inverse relationship between these two properties. By adjusting two key variables—the tungsten carbide grain size and the cobalt content—engineers can precisely tailor the material’s properties to suit specific working conditions.

- Pursuing Higher Hardness: This is achieved by reducing the cobalt content and decreasing the tungsten carbide grain size. A lower cobalt content means a higher volume fraction of the hard phase, leading to closer contact between tungsten carbide particles and thus maximizing the material’s wear resistance. Finer grains (according to the Hall-Petch effect) also significantly increase hardness. Such materials are suitable for high-wear, high-precision finishing applications.

- Pursuing Higher Toughness: This is achieved by increasing the cobalt content and using coarser tungsten carbide grains. A higher cobalt content forms a thicker, more continuous binder phase network that can more effectively absorb impact energy and inhibit crack propagation. These materials are better suited for interrupted cutting, heavy-load conditions, or roughing and mining applications where vibrations are present.

This ability for precise control explains why there are hundreds of different cemented carbide grades on the market. Each grade represents a specific optimization point on the hardness-toughness spectrum, designed to address particular failure modes, such as abrasive wear in finishing hardened steel or impact fracture in rough milling of stainless steel.

1.2 Alloying and Additives: Tailoring Performance for Specific Applications

While the basic WC-Co system offers excellent performance, other alloying elements are introduced to cope with more severe and complex working conditions.

Cubic Carbides (γ-phase)

Early WC-Co alloys, when used for high-speed cutting of steel, suffered from rapid crater wear on the tool’s rake face due to chemical diffusion reactions with the hot chips, leading to tool failure.To solve this problem, researchers added cubic crystal structure carbides such as titanium carbide (TiC), tantalum carbide (TaC), and niobium carbide (NbC) to the composition.At high temperatures, these carbides form a solid solution with tungsten carbide, known as the γ-phase. The presence of the γ-phase significantly improves the material’s high-temperature hardness (or “hot hardness”) and oxidation resistance, effectively suppressing crater wear. This led to the creation of cemented carbide grades specifically for steel machining.This development was a milestone in the history of cemented carbide. It was not just a performance improvement but a fundamental change in the material’s phase composition that successfully overcame a key application bottleneck, opening up the vast steel machining market for cemented carbide.

Grain Growth Inhibitors

During the high-temperature sintering process, trace amounts of vanadium carbide (VC) and chromium carbide (Cr3C2) are often added to prevent the excessive growth of tungsten carbide grains, which would otherwise lead to a decrease in hardness and strength. These additives effectively pin the grain boundaries of tungsten carbide, hindering grain boundary migration and ensuring that the final material achieves the desired fine and uniform microstructure.

Alternative Binder Systems

Although cobalt is the dominant binder, research into alternative binders has never ceased, driven by factors such as cost, strategic resource security, and occupational health concerns. For example, nickel (Ni), iron (Fe), and their alloys (such as Co-Ni, Fe-Ni) are also used as binder phases to adjust the material’s corrosion resistance, magnetic properties, or other specific characteristics.

1.3 Microstructure and Its Impact on Mechanical Properties

The final performance of cemented carbide is determined by its microstructure. The ideal structure consists of hard α-phase (WC) particles uniformly distributed in a tough β-phase (Co) matrix, with the γ-phase present as needed.The quality of the material depends on the uniformity of the binder phase distribution and the absence of tungsten carbide particle agglomeration.

Process control during production is crucial. Defects such as porosity must be strictly avoided, and the carbon content in the system must be precisely controlled. Too low a carbon content leads to the formation of the brittle η-phase (a W-Co complex carbide), while too high a carbon content results in the precipitation of free graphite. Both conditions severely degrade the material’s mechanical properties.

Key performance indicators for cemented carbide include:

- Hardness: Typically measured using the Rockwell Hardness A-scale (HRA) or Vickers Hardness (HV).

- Strength: Usually characterized by Transverse Rupture Strength (TRS), which reflects the material’s ability to resist fracture under bending loads.

- Fracture Toughness (KIC): A measure of the material’s resistance to crack propagation.

- Thermal Stability: A standout advantage of cemented carbide is its ability to maintain a high degree of hardness at elevated temperatures. Its performance remains largely unchanged even at 500°C, and at 1000°C, it is still far superior to high-speed steel, which is the fundamental reason it can achieve high-speed cutting.

Section 2: The Powder Metallurgy Manufacturing Process

The unique properties of cemented carbide make it impossible to produce through traditional melting and casting methods. Instead, it must be manufactured using powder metallurgy processes. This process route is not just a forming method but a critical stage that determines the final microstructure and performance of the material. The entire process requires extremely high precision and strict control.

2.1 Raw Material Preparation and Mixing

The process begins with high-purity, fine raw material powders, including tungsten carbide, cobalt, and other required carbides and additives. The particle size of the raw powders is typically in the range of 1-2 micrometers or even finer sub-micron levels.The various powders are precisely weighed according to the specific grade’s formula and then added to a wet ball mill. Alcohol or another organic medium is usually added for wet milling to ensure the components are thoroughly mixed and further refined, and to prevent the powders from oxidizing during mixing.

2.2 Milling, Drying, and Granulation

Prolonged milling in the ball mill ensures the microscopic uniformity of the raw materials. The slurry from wet milling is then dried to remove the milling medium, resulting in a uniform composite powder. Subsequently, an organic forming agent, such as paraffin wax or polyethylene glycol (PEG), is added to the powder. The purpose of the forming agent is to provide lubrication for the powder particles during the subsequent pressing stage and to give the pressed “green compact” a certain level of strength (known as “green strength”) for easy handling. The powder mixed with the forming agent is often processed through spray drying to form spherical granules with good flowability, facilitating automatic pressing.

2.3 Pressing and Forming

The prepared mixture is placed into a high-precision mold and subjected to high pressure in a press to form a pre-shaped blank, known as a “green compact”. For carbide rods, rigid die pressing or cold isostatic pressing techniques are commonly used. For rods with complex internal coolant holes (such as helical holes), more advanced processes like extrusion or metal injection molding (MIM) may be employed. At this stage, the green compact is porous and has low strength but already has the basic shape of the final product.

2.4 Sintering: The Core of the Process

Sintering is the most critical step in the entire process. The green compacts are placed in a vacuum sintering furnace or a controlled atmosphere furnace and heated to between 1300°C and 1600°C.

- Liquid Phase Sintering: This temperature is well below the melting point of tungsten carbide but above the melting point of the cobalt binder. When the temperature exceeds the eutectic point, the cobalt melts into a liquid phase. Under the action of capillary forces, the liquid cobalt rapidly penetrates the gaps between the tungsten carbide particles, pulling them closer together and filling all the pores.

- Densification and Shrinkage: As the pores are eliminated, the body undergoes a significant and predictable volume shrinkage, typically around 50%. This means that the mold design must precisely account for this shrinkage. During the sintering process, the green compact is transformed into a fully dense, non-porous, solid body.

The temperature, time, heating rate, vacuum level, and atmosphere control throughout the sintering process have a decisive impact on the final product’s performance. Any slight deviation can lead to the aforementioned decarburization or carburization phenomena, or result in defects like porosity. Therefore, the quality of the final product depends less on the raw materials themselves and more on the manufacturer’s ability to precisely control this complex, multi-stage process. This is where the core technical knowledge and competitive advantage in the cemented carbide manufacturing industry lie.

2.5 Post-Sintering Treatment

The sintered rods are extremely hard, and any subsequent dimensional finishing must be done by grinding with diamond wheels. Finally, the products undergo rigorous quality inspection, including dimensional accuracy, visual defects, density, hardness, magnetic saturation, and a series of other performance tests to ensure they meet technical specifications.

Section 3: Classification and Standardization of Carbide Rods

The classification system for carbide rods is complex and precise, designed to meet the diverse needs of downstream tool manufacturers. Classification is primarily based on national standards, manufacturer grades, geometric shapes, and surface finishes.

3.1 Standards and Grades

Although there is no single, universally unified classification system for cemented carbide (except for metal cutting applications) , many countries and regions have developed their own standards. For example, China’s GB/T 18376.1-2008 standard specifies the grades for cemented carbide cutting tools. In practice, however, major manufacturers typically use their proprietary grade systems, such as Hyperion’s K10F grade or GESAC’s GU25UF grade. These grade codes contain detailed information about the material, such as its chemical composition, grain size, performance characteristics, and recommended application areas.

3.2 Classification by Geometry and Function

This is the most practical classification for tool designers, as it directly relates to the design and manufacturing efficiency of the final tool.

- Solid Rods and Rods with Coolant Holes: Solid round rods (code: BR) are the most basic type. Rods with internal coolant channels are crucial for high-performance drilling and milling, as they deliver coolant directly to the cutting edge area. This effectively cools, lubricates, and flushes away chips, significantly extending tool life and improving machining efficiency.

- Coolant Hole Geometry: The design of coolant holes is diverse, including single straight central holes (code: GA), two straight holes (GB), two helical holes (GD), and three helical holes (GE). The helix angle of the helical holes (e.g., 30° or 40°) is also an important parameter. Although more complex to manufacture, helical holes are better for chip evacuation in rotating tools like drills.

- End Geometry: To reduce the subsequent grinding operations for tool manufacturers, rod suppliers can provide products with specific end features. Common examples include chamfered ends (code: 2), ball nose ends (BQ), and tapered ends (BZ).

3.3 Classification by Grade and Finish

- Manufacturer Grades: As mentioned earlier, these proprietary codes are key to distinguishing material performance and application ranges. For example, one grade might be designed for machining hardened steel, while another is suitable for machining aluminum alloys.

- Surface Finish: Rods are graded according to their processing state. This directly affects the machining allowance and precision of subsequent operations. Common codes include H0 (unground), H1 (semi-fine ground), H2 (ground to h6 tolerance), and H7 (ground to h5 tolerance). Tool manufacturers select the appropriate finish level based on the precision of their equipment and the requirements of the final product.

The table below summarizes the common classification codes for carbide rods, providing a practical reference for engineers and purchasing personnel to decode manufacturer product catalogs.

Table 3.1: Carbide Rod Classification Code Reference

| Category | Code | Description |

| Product Form | BR | Solid Rods |

| GA | Rods with Central Coolant Hole | |

| GB | Rods with 2 Straight Coolant Holes | |

| GD | Rods with 2 Helical Coolant Holes | |

| BQ | Ballnose Endmill Blanks | |

| BZ | Rods with Tapered End | |

| Grinding State | H0 | Unground |

| H1 | Semi Fine Ground | |

| H2 | Ground h6 | |

| H7 | Ground h5 | |

| End Feature | 1 | No Chamfer |

| 2 | Chamfer | |

| 3 | Slot | |

| 4 | Tapered End |

Section 4: Performance and Applications in Modern Industry

The exceptional performance of cemented carbide makes it an indispensable key material in modern industry, with its advantages becoming even more apparent when compared to traditional tool materials.

4.1 Performance Comparison: Cemented Carbide vs. High-Speed Steel (HSS)

- Performance Metrics: Compared to high-speed steel, cemented carbide has an overwhelming advantage in several core performance dimensions. It is harder, more wear-resistant, and has excellent heat resistance. This superior hot hardness allows carbide tools to maintain the sharpness and strength of their cutting edges at the high local temperatures (up to 800-1000°C) generated during high-speed cutting, whereas the hardness of HSS drops sharply above 500-600°C. Therefore, in most applications, the cutting speed of carbide tools can be several times that of HSS, leading to a huge leap in production efficiency and longer tool life.

- Cost-Effectiveness and Application Scenarios: Although the initial purchase cost of carbide tools is significantly higher than that of HSS tools, their economic efficiency is actually better under large-scale, stable production conditions. Higher machining parameters mean shorter processing times per piece, and longer life means less downtime for tool changes, which reduces the overall manufacturing cost per unit. However, HSS, with its better toughness and lower cost, remains the more economical choice for small-batch production, situations with insufficient machine tool rigidity or unstable conditions, and specific machining operations that require extremely sharp edges.

4.2 Key Industrial Applications

As a raw material, carbide rods find their ultimate applications across all pillar industries of the national economy.

- Cutting Tools: This is the primary application area for cemented carbide. Rods are processed into solid end mills, drills, reamers, taps, and other types of rotating tools used for cutting almost all engineering materials, from common steels and cast iron to non-ferrous metals, plastics, composites, graphite, and glass.

- Aerospace: This sector extensively uses difficult-to-machine materials like titanium alloys and nickel-based superalloys (e.g., Inconel), which have excellent high-temperature strength and corrosion resistance but also pose significant challenges to machining. Only high-performance carbide tools (often requiring specific grades and advanced coatings) can effectively and economically machine these materials to produce critical components such as turbine disks, blades for aircraft engines, and structural parts for aircraft.16 From this perspective, cemented carbide is not just an improved tool material but an “enabling technology.” Without the development of high-performance cemented carbide, the widespread application of these advanced materials in the modern aerospace industry would be unimaginable; it directly drives technological progress in the entire field.

- Automotive Manufacturing: The automotive industry is a model of high-efficiency, high-precision, large-volume production, which is precisely where carbide tools excel. From the machining of engine blocks, crankshafts, and transmission gears to the cold and hot forging of chassis parts and the stamping of body panels, carbide tools, dies, and fixtures are ubiquitous.

- Mold and Die Manufacturing: The high compressive strength and extreme wear resistance of cemented carbide make it an ideal material for manufacturing various long-life molds and dies. This includes hardware dies for metal drawing, stamping, and cold heading; powder metallurgy dies for powder compaction; and high-precision injection molds for mass-producing plastic products.

- Mining, Construction, and Energy: In these fields, the toughness and wear resistance of cemented carbide are fully demonstrated. It is used to make various drill bits and cutting picks for mining, tunneling, rock drilling, and oil and gas exploration.

Section 5: Advanced Surface Engineering: The Role of Coatings

While the cemented carbide substrate provides the fundamental strength and toughness of a tool, a surface coating just a few micrometers thick (1-20 µm) can elevate its performance to a new level. Coating technology is an indispensable part of modern high-performance cutting tools.

5.1 The Necessity of Coatings

A coating forms a powerful functional barrier on the tool’s surface. It can effectively insulate against cutting heat, reduce the coefficient of friction, and provide a working surface that is harder and more chemically stable than the substrate itself, thereby resisting abrasive wear and chemical diffusion at high temperatures. The result is a significant extension of tool life (typically 1.5 to 3 times, or even more) and the ability to use higher cutting speeds and feed rates, further boosting production efficiency.

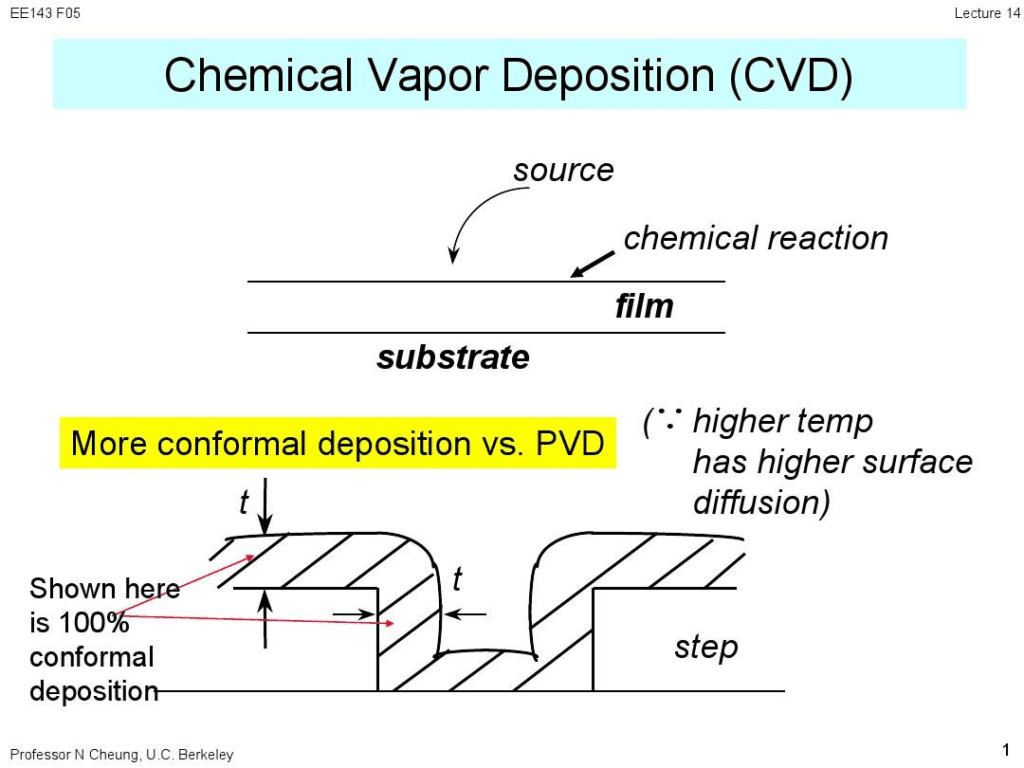

5.2 Chemical Vapor Deposition (CVD)

- Process: This is a high-temperature process (typically 800-1000°C) where gaseous reactants undergo a chemical reaction in a vacuum or specific atmosphere, forming and depositing a dense compound film on the tool’s surface.

- Characteristics: CVD coatings are generally thicker (5-20 µm), have strong adhesion to the substrate, and possess extremely high wear resistance. Common CVD coating materials include titanium carbide (TiC), titanium carbonitride (TiCN), and aluminum oxide (Al2O3).20 The disadvantage is that the high-temperature process can slightly reduce the substrate’s toughness and cause minor dulling of the cutting edge, making it less suitable for tools that require extreme sharpness.

- Applications: CVD coatings are the first choice for applications where wear resistance is the dominant requirement, such as roughing and semi-finishing turning and drilling of steel and cast iron.

5.3 Physical Vapor Deposition (PVD)

- Process: This is a low-temperature vacuum process (typically 200-600°C) where a target material is vaporized by physical means (such as sputtering or arc evaporation) and then condensed onto the tool’s surface to form a film.

- Characteristics: PVD coatings are thinner (1-5 µm), have a smooth surface, and lower internal stress. Due to the low process temperature, it preserves the toughness of the carbide substrate and the original sharpness of the cutting edge. PVD technology is applicable to a wider range of substrates, including high-speed steel.

- Applications: PVD coatings are ideal for applications requiring sharp edges and high toughness, such as milling, drilling, threading, and finishing. They perform particularly well when machining materials that are prone to adhesion, like stainless steel and aluminum alloys, effectively inhibiting the formation of built-up edge.

5.4 Modern Coating Materials and Structures

- Advanced Nitride Coatings: Modern coating technology has advanced far beyond the early titanium nitride (TiN). The new generation of coatings, represented by titanium aluminum nitride (TiAlN), aluminum titanium nitride (AlTiN), and aluminum chromium nitride (AlCrN), have become mainstream due to their excellent hot hardness and high-temperature oxidation resistance. The aluminum in these coatings forms a dense protective layer of aluminum oxide (Al2O3) on the tool surface at high temperatures, effectively preventing further oxidation of the tool. This is key to achieving high-speed dry cutting.

- Advanced Structural Designs: Modern coatings are no longer simple single-layer structures but have evolved into complex structures such as multilayer, nanolayer, gradient, and nanocomposite designs. These sophisticated structural designs can effectively deflect crack propagation, manage internal stress in the coating, and combine the advantages of different materials. For example, a high-hardness wear-resistant layer can be placed on top of a high-toughness bonding layer to achieve optimal overall performance.

- Diamond Coatings: This is a special type of CVD coating with unparalleled hardness. It is specifically used for machining highly abrasive non-metallic and non-ferrous materials, such as graphite, carbon fiber reinforced plastics (CFRP), high-silicon aluminum alloys, and ceramics.

The design philosophy for modern high-performance cutting tools has evolved into a “surface system engineering” concept. It is no longer a single material but a precision system composed of three parts: the cemented carbide substrate that provides core strength and toughness, the coating that provides wear resistance, lubrication, and a thermal barrier, and the specific edge preparation (such as honing, polishing, or brushing) achieved through micro-processing. These three elements must be designed in synergy and perfectly matched to achieve ultimate performance in a specific application. This explains why tool manufacturers invest heavily in R&D for substrate materials, coating technologies, and edge preparation processes. It is a holistic design philosophy that reflects the complexity and high added value of modern tool technology.

Table 5.1: Comparative Analysis of PVD and CVD Coating Technologies

| Feature | CVD (Chemical Vapor Deposition) | PVD (Physical Vapor Deposition) |

| Process Temperature | High (800 – 1000°C) | Low (200 – 600°C) |

| Coating Thickness | Thicker (5 – 20 µm) | Thinner (1 – 5 µm) |

| Hardness | Extremely high, strong wear resistance | High, smooth surface |

| Substrate Toughness Retention | Some impact | Minimal impact, mostly retained |

| Edge Sharpness | Slight dulling | Retains original sharpness |

| Typical Coating Materials | TiC, TiCN, Al2O3 | TiN, TiCN, TiAlN, AlTiN, AlCrN |

| Primary Applications | Turning and drilling of steel, cast iron (especially roughing) | Milling, drilling, threading, finishing; machining of stainless steel, superalloys, aluminum alloys |

| Advantages | Excellent wear resistance, strong adhesion, thick coating | Sharp edges, good substrate property retention, high surface finish, low friction coefficient |

| Disadvantages | High process temperature, edge dulling, not suitable for heat-sensitive substrates | Relatively thin coating, may have shorter life than CVD in extreme wear conditions |

Section 6: Future Outlook for Cemented Carbide Technology

As a mature industry with a century-long history, cemented carbide technology is facing a series of disruptive pressures and opportunities. Its future development will no longer be a slow, linear evolution but a profound transformation driven by multiple forces.

6.1 Expanding the Frontiers of Material Science: Nanocrystalline Cemented Carbides

The pursuit of finer grain sizes is pushing cemented carbide into the nanoscale (grain size <100 nm). According to the Hall-Petch relationship, smaller grains mean more grain boundaries, which can more effectively impede dislocation movement, thereby giving the material higher hardness and wear resistance than traditional micro-grained materials. Nanocrystalline cemented carbides are expected to show excellent performance in cutting-edge fields such as ultra-precision machining, micro-machining, and cutting of hardened materials.

6.2 Innovation in Binder Technology: The Quest for Cobalt Alternatives

Several factors are driving the research and development of cobalt alternatives: the price volatility and supply chain risks of cobalt as a strategic resource, and increasingly strict international regulations regarding the occupational health and environmental impacts of cobalt dust.

- Alternative Binders: Current research focuses mainly on binder systems based on nickel (Ni), iron (Fe), and their alloys (such as Fe-Ni, Co-Ni-Fe). Additionally, to meet the demands of extreme high-temperature applications, some studies are exploring the possibility of using special metals like rhenium (Re) as binders.

- High-Entropy Alloys (HEAs): This is a disruptive new approach that uses multi-component alloys containing five or more principal elements (such as AlFeCoNiCrTi) as the binder phase. HEAs themselves possess excellent high-temperature strength, corrosion resistance, and wear resistance. During sintering, they can also inhibit the growth of tungsten carbide grains, promising the development of a new generation of cemented carbides with both higher hardness and toughness.

6.3 The Rise of Additive Manufacturing (3D Printing)

Additive manufacturing technology brings unprecedented freedom to the design and manufacturing of cemented carbide tools. It has the potential to create complex geometries that are impossible with traditional press-and-sinter processes, such as topologically optimized internal cooling channels, integrally formed special-shaped tools, and even functionally graded materials where the composition varies within the tool. Although the application of this technology in the cemented carbide field is still in its early stages, it opens up a new path for developing highly customized, ultra-high-performance tools.

6.4 Sustainability and the Circular Economy: Recycling

Tungsten is a rare and non-renewable resource, which makes the recycling of cemented carbide crucial from both economic and environmental perspectives. The high value of tungsten and cobalt in used cemented carbide provides a strong incentive for building a circular economy.

- Recycling Processes: There are currently two main mature recycling methods:

- Zinc Process: This is a physico-chemical method where molten zinc penetrates the scrap material and reacts with the cobalt binder, causing it to swell and break down the cemented carbide structure into powder. The recovered powder can be reprocessed and used directly in production.

- Chemical Process: This is a hydrometallurgical process where the scrap material is completely dissolved in chemical solvents, returning it to its atomic components. Through a series of chemical steps such as purification and extraction, “reclaimed” raw material powder with a quality identical to virgin powder is produced.

Practice has shown that powder recovered through advanced processes has the same quality and performance as virgin powder, making recycling a stable, reliable, and environmentally friendly source of key raw materials in the cemented carbide industry chain.

Conclusion

Carbide rod is a highly engineered composite material whose exceptional performance stems from the ability to tailor its properties through precise control of chemical composition and microstructure. Since its inception, the development of cemented carbide has been closely linked to the progress of modern manufacturing, becoming an important indicator of a country’s industrial level.

The success of cemented carbide is the result of the synergistic effect of multiple technologies: fundamental material science (which determines the intrinsic potential of a grade), precision powder metallurgy processes (which transform material potential into a real product), and advanced surface engineering technologies (which elevate product performance to its limits). These three areas are interdependent and have co-evolved, always with the ultimate goal of meeting the stringent demands of industrial applications.

Although cemented carbide is a technology with a century-long history, it remains vibrant and critically important. Looking to the future, driven by cutting-edge technologies such as nanomaterials, cobalt-free binders, and additive manufacturing, combined with a growing emphasis on sustainable development and the circular economy, cemented carbide is set to play a key role in an even broader range of fields. It will continue to serve as the cornerstone of advanced manufacturing, driving the continuous progress of human industrial civilization.