Bull Nose End Mill vs Ball Nose: Choosing the Right Tool for Your Job

In the world of CNC machining and metalworking, choosing the right cutting tool can make all the difference in the quality, efficiency, and success of your project. Two popular types of end mills that often come up in discussions are bull nose end mills and ball nose end mills. While they may sound similar, these tools have distinct characteristics and applications. In this comprehensive guide, we’ll explore the differences between bull nose end mill vs ball nose, and also touch on how they compare to flat end mills. By the end of this article, you’ll have a clear understanding of which tool is best suited for your specific machining needs.

Understanding End Mills: The Basics

Before diving into the specifics of bull nose and ball nose end mills, let’s briefly review what an end mill is and its importance in machining operations.

An end mill is a type of milling cutter, a rotary cutting tool used in milling machines or machining centers. These versatile tools are designed to remove material from a workpiece by moving along various axes while rotating. End mills come in various shapes, sizes, and configurations, each optimized for specific types of cuts and materials.

Now, let’s focus on our main comparison: bull nose end mill vs ball nose end mill.

Bull Nose End Mills: Features and Applications

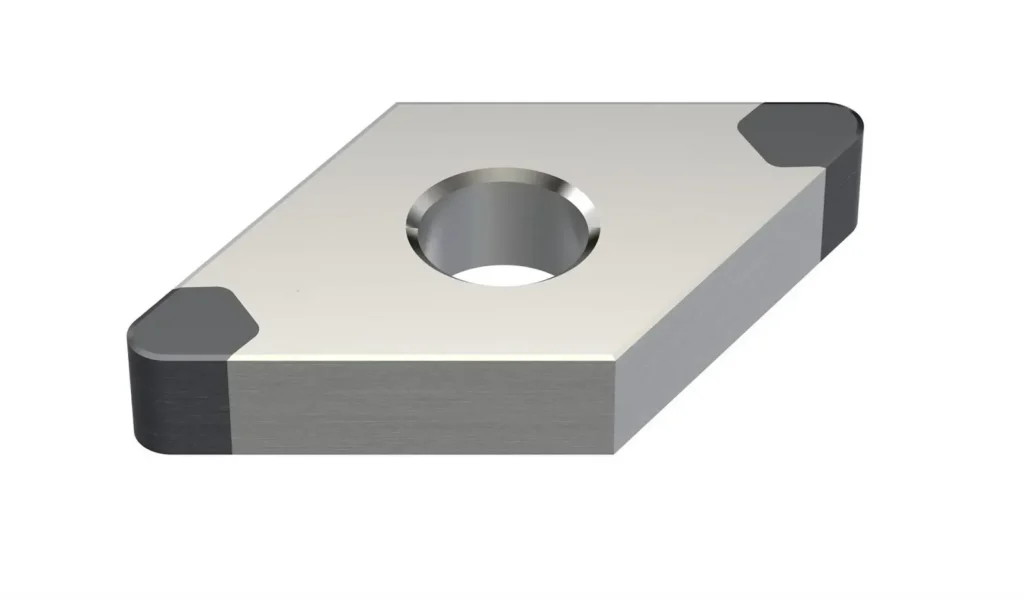

Bull nose end mills, also known as corner radius end mills or radius end mills, are characterized by their unique shape. They feature a flat bottom with rounded corners, effectively combining elements of both flat and ball end mills.

Key features of bull nose end mills:

- Flat cutting surface with rounded corners

- Corner radius smaller than the tool’s radius

- Available in various corner radii sizes

Applications of bull nose end mills:

- Facing operations

- Slotting with rounded internal corners

- Contouring with a flat bottom

- Blending flat and curved surfaces

- Creating fillets and rounded edges

Advantages of bull nose end mills:

- Faster material removal compared to ball nose end mills

- Stronger cutting edge due to more material support

- Leaves a smoother finish on flat surfaces

- Reduces the risk of chipping in brittle materials

- Ideal for roughing and semi-finishing operations

Ball Nose End Mills: Features and Applications

Ball nose end mills, also called spherical end mills or ball end mills, are distinguished by their hemispherical (half-ball) cutting end. The radius of the cutting end is equal to the tool’s radius, creating a continuous curved surface.

Key features of ball nose end mills:

- Hemispherical cutting end

- Radius equal to the tool’s radius

- Continuous curved cutting edge

Applications of ball nose end mills:

- 3D contouring and sculpting

- Finishing curved surfaces

- Creating rounded bottoms in pockets and cavities

- Machining complex geometries

- Producing fine details in molds and dies

Advantages of ball nose end mills:

- Excellent for machining curved and complex surfaces

- Provides a consistent finish on 3D contours

- Allows for smooth tool path transitions

- Ideal for finishing operations

- Reduces the need for secondary finishing processes

Bull Nose End Mill vs Ball Nose: Key Differences

Now that we’ve explored the features and applications of both types, let’s directly compare bull nose end mills vs ball nose end mills:

- Cutting Profile:

- Bull nose: Produces a flat surface with rounded internal corners

- Ball nose: Creates a scalloped or wavy surface

- Material Removal Rate:

- Bull nose: Generally faster due to larger flat cutting area

- Ball nose: Typically slower, especially on flat surfaces

- Surface Finish:

- Bull nose: Smoother finish on flat surfaces

- Ball nose: More consistent finish on curved surfaces

- Strength and Rigidity:

- Bull nose: Generally stronger due to more material at the cutting edge

- Ball nose: More prone to deflection, especially in longer tools

- Versatility:

- Bull nose: Good for both roughing and finishing, especially on flat surfaces

- Ball nose: Excels in finishing curved surfaces but less efficient for roughing

- Tool Path Programming:

- Bull nose: Simpler tool paths for flat surfaces with rounded corners

- Ball nose: More complex tool paths required for optimal surface finish

Ball End Mill vs Flat End Mill: A Quick Comparison

To provide a more comprehensive understanding, let’s briefly compare ball end mills and flat end mills:

Flat end mills:

- Feature a flat cutting end perpendicular to the tool axis

- Ideal for creating square shoulders, slots, and pockets with flat bottoms

- Offer faster material removal rates on flat surfaces

- Provide sharp internal corners

Ball end mills:

- Feature a hemispherical cutting end

- Excel at 3D contouring and curved surfaces

- Leave no sharp internal corners

- Offer more versatility for complex geometries

Choosing the Right End Mill for Your Project

When deciding between a bull nose end mill vs ball nose end mill (or even a flat end mill), consider the following factors:

- Workpiece Geometry:

- Flat surfaces with rounded corners: Bull nose

- Complex curved surfaces: Ball nose

- Flat surfaces with sharp corners: Flat end mill

- Operation Type:

- Roughing: Bull nose or flat end mill

- Finishing on curves: Ball nose

- Finishing on flats: Bull nose or flat end mill

- Material:

- Harder materials may benefit from the stronger cutting edge of a bull nose

- Softer materials can be machined effectively with any type

- Surface Finish Requirements:

- High-quality finish on curves: Ball nose

- Smooth flat surfaces: Bull nose or flat end mill

- Tool Life and Rigidity:

- For longer tool life and reduced deflection: Bull nose or flat end mill

- For complex geometries where some deflection is acceptable: Ball nose

- Machining Time:

- Faster material removal on flats: Bull nose or flat end mill

- Efficient 3D contouring: Ball nose

Conclusion

Understanding the differences between bull nose end mills vs ball nose end mills, as well as how they compare to flat end mills, is crucial for optimizing your machining operations. Each type of end mill has its strengths and ideal applications. Bull nose end mills offer a great balance between material removal rate and surface finish, especially for flat surfaces with rounded corners. Ball nose end mills excel in 3D contouring and complex curved surfaces. Flat end mills remain the go-to choice for creating sharp corners and rapid material removal on flat surfaces.

By carefully considering your project requirements, workpiece geometry, and desired outcomes, you can select the most appropriate end mill type. Remember that in many complex machining projects, a combination of different end mill types may be necessary to achieve the best results. Don’t hesitate to experiment with different tools and consult with experienced machinists or tool manufacturers to fine-tune your selection and machining strategies.

What is the difference between end mills and ball mills?

Key Differences:

Cutting profile:

End mills: Produce flat surfaces or sharp corners

Ball mills: Create curved or scalloped surfaces

Material removal rate:

End mills: Generally faster, especially on flat surfaces

Ball mills: Typically slower, but better for curved surfaces

Precision:

End mills: More precise for flat surfaces and sharp features

Ball mills: Better for smooth, continuous curved surfaces

Programming:

End mills: Simpler toolpaths for flat surfaces

Ball mills: More complex toolpaths for 3D contouring

Strength:

End mills: Generally stronger due to more material support

Ball mills: More prone to deflection, especially in longer tools

Why use a ball end mill?

Ball end mills are essential cutting tools in machining operations, primarily valued for their unique hemispherical shape that excels in 3D contouring and finishing curved surfaces. They are the go-to choice for creating smooth, complex geometries in mold and die making, producing rounded corners and fillets, and achieving consistent finishes on contoured surfaces. Their ability to distribute cutting forces over a larger area often results in reduced tool wear and improved surface quality. While they may not be as efficient as flat or bull nose end mills for material removal on flat surfaces, ball end mills shine in applications requiring intricate detail work, smooth toolpaths, and access to tight spaces or deep cavities. Their versatility in handling complex 3D shapes and providing superior finish on curved surfaces makes them indispensable in modern CNC machining, especially for industries that demand high-precision, aesthetically pleasing components with complex geometries.

What is an end mill used for?

An end mill is a versatile cutting tool used in various machining operations, particularly in milling machines and CNC machining centers. It is designed to remove material from a workpiece by combining rotary cutting with lateral movement. End mills are employed for a wide range of tasks, including face milling, profile milling, slot cutting, plunge cutting, and creating pockets or cavities. They can perform both roughing and finishing operations on flat surfaces, contours, and 3D shapes. End mills come in various types (such as flat, ball nose, and bull nose) and sizes, each optimized for specific applications. They are capable of cutting in multiple directions – axially, radially, and in combined movements – making them indispensable for producing complex parts in industries like aerospace, automotive, mold making, and general manufacturing. The versatility of end mills allows machinists to create precise features, achieve desired surface finishes, and work with a variety of materials, from soft plastics to hardened steels, making them a fundamental tool in modern machining processes.

What are the reasons that you Cannot use end mill as a drill?

End mills are not designed to be used as drill bits due to several critical differences in their design and intended function. Unlike drill bits, end mills lack the specialized point geometry necessary for efficient hole-starting and are not optimized for axial cutting forces or vertical chip evacuation. Their flute design is geared towards lateral cutting rather than plunging, which can lead to chip clogging and overheating when used for drilling. Many end mills are not center-cutting, making it difficult to initiate a hole, and they typically lack the internal coolant channels found in drill bits, crucial for deep hole applications. Furthermore, end mills operate at different cutting speeds than drill bits and may produce less accurate or rougher holes when used for drilling. Using an end mill as a drill can result in poor hole quality, reduced tool life, and potential tool breakage or deflection due to the mismatched cutting forces. While end mills can sometimes be used to enlarge existing holes or create shallow holes in certain situations, they are generally not suitable or efficient as primary drilling tools.