Boring Bars

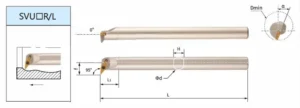

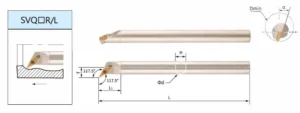

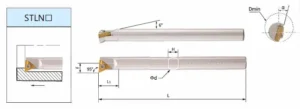

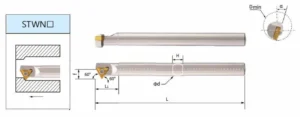

Boring Bars are essential cutting tools used in machining to enlarge or finish existing holes to precise internal diameters. Primarily employed on lathes, milling machines, and boring mills, a lathe boring bar is a common type used for internal turning operations. The fundamental purpose of a boring bar tool is to create or refine the inner surface of a workpiece, ensuring accuracy and a desired finish.

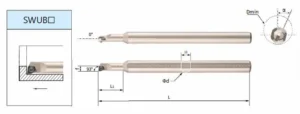

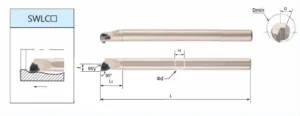

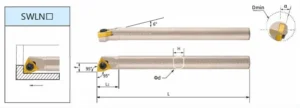

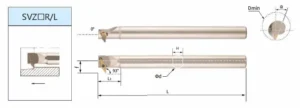

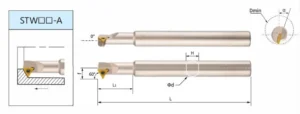

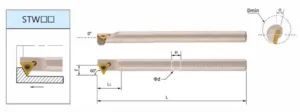

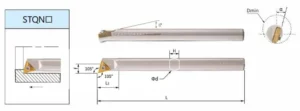

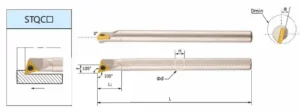

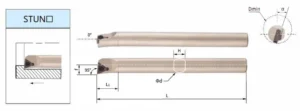

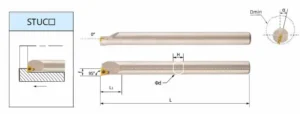

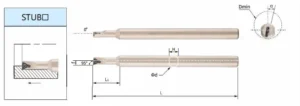

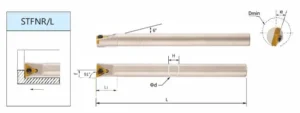

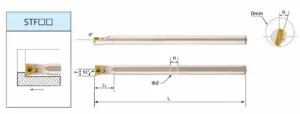

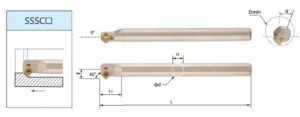

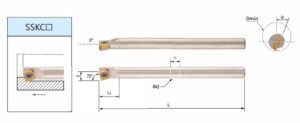

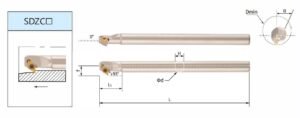

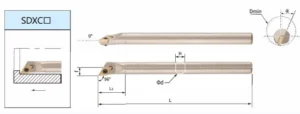

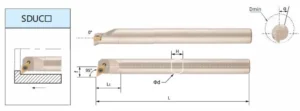

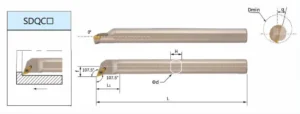

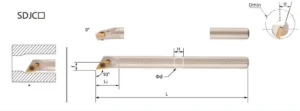

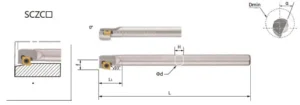

A boring bar holder is crucial for securely mounting the boring bar to the machine, providing the necessary rigidity to prevent vibration and chatter during the cutting process. Various types of boring bars cater to different machining needs. An indexable boring bar utilizes replaceable cutting inserts, offering versatility and ease of tool change. These inserts come in various shapes and materials to suit different workpiece materials and machining requirements. For applications demanding fine adjustments to the bore diameter, an adjustable boring bar allows for precise tuning of the cutting tool position.

When working with smaller holes, a small boring bar is necessary to fit within the limited space while still providing adequate rigidity for accurate machining. In modern manufacturing, cnc boring bar systems are widely used in automated machining processes, ensuring high precision and repeatability. For demanding applications requiring maximum stability and vibration damping, especially when working with long overhangs or challenging materials, heavy metal boring bars, often made from materials like tungsten carbide or heavy alloys, are employed. These materials offer superior stiffness and mass, minimizing deflection and improving machining accuracy. In summary, Boring Bars are critical tools for achieving precise internal dimensions and finishes in a wide range of machining applications.

Frequently Asked Questions

Center the boring bar by adjusting its height in the tool holder using shims or an adjustable tool post so the cutting edge is aligned with the lathe’s spindle centerline.

Generally involves selecting a suitable material (like high-speed steel), grinding the cutting edge to the desired shape and angle, and potentially hardening and tempering for increased durability.

This is a more complex process often involving a long bar with precisely machined mounting points for adjustable cutting heads. It may require welding or fabrication of multiple components.

Mount the boring bar securely in the tool holder with minimal overhang, ensuring it’s properly centered with the lathe’s spindle centerline.

Secure the workpiece, select appropriate spindle speed and feed, and make controlled passes with the boring bar to enlarge the existing hole to the desired diameter and finish.

A rigid cutting tool used to enlarge or finish existing holes to precise internal diameters.

To achieve accurate internal dimensions and surface finishes in holes.

Mount and center the boring bar, secure the workpiece, select appropriate cutting parameters (speed, feed, depth of cut), and make controlled passes, adjusting depth as needed until the desired bore size is reached.

Similar to making a regular boring bar but using smaller diameter stock material and paying close attention to the grinding process to create a precise cutting edge.

Contact Us for Your Tool Holders

Please note: We are a wholesale supplier and have minimum order quantities.