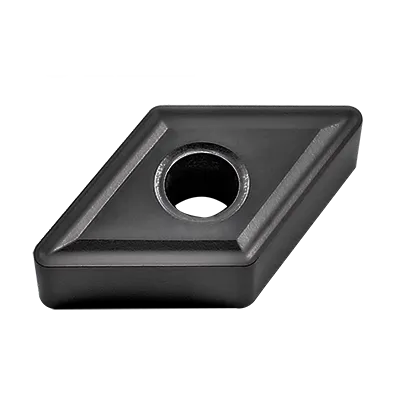

DNMG insert

DNMG insert angle: 0° Negative Rake Insert with double-sided Chipbreaker;

55° rhombic turning insert;

Recommended for steel, stainless steel, and cast iron and etc;

Breaker Application: Rough, Semi-finishing, Finishing machining;

Matching DNMG insert holder: PDJNR/L, PDNN, MDJNR, MDPNN;

Application industry: DNMG Insert is widely applied in automobile, aerospace, 3C and other industries;

Range of DNMG insert types:DNMG150404/DNMG150408/DNMG331/DNMG332/DNMG431/DNMG432/DNMG/433;

Grade: Both PVD and CVD;

Material : Tungsten Carbide;

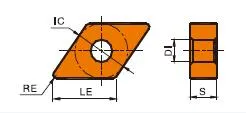

DNMG insert specification

Our premium DNMG inserts are crafted from high-quality cemented carbide for exceptional performance.

Advanced quenching techniques and specialized surface coatings make them incredibly durable, resisting wear, heat, impact, and corrosion.

Plus, we’ll customize them to perfectly match your equipment and working conditions.

Expect unmatched accuracy, long service life, and outstanding cost-effectiveness.

That’s why these inserts are trusted worldwide in demanding industries like automotive, aerospace, and 3C manufacturing.

DNMG insert Meaning

Understanding the DNMG Insert Code

- D: Shape: Rhombic (diamond) with a 55-degree included angle.

- N: Clearance Angle: 0 degrees.

- M: Tolerance: Medium tolerance is standard, though other precision tolerances may exist.

- G: Chipbreaker style & Hole Configuration. This letter designates the specific chipbreaker geometry and whether the insert has a hole or not. Chipbreaker variations are numerous and manufacturer-specific.

- Numerical Digits:

- First Two Digits: Inscribed circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

- Next Two Digits: Thickness in millimeters. Divide by 25.4 to convert to inches.

- Last Two Digits: Nose radius in millimeters. To convert to inches, divide by 25.4.

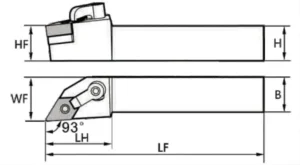

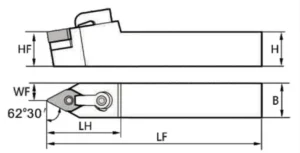

DNMG insert holder

MDJNRL

MDPNN

DNMG Insert Dimensions (ISO and INCH)

| DNMG Designation(ISO) | DNMG Designation(INCH) | Inscribed Circle (IC) | Thickness | Common Corner Radii |

|---|---|---|---|---|

| DNMG 110404 | DNMG331 | 11mm (0.433") | 4.76mm (0.187") | 0.4mm (0.016") |

| DNMG 110408 | DNMG332 | 11mm (0.433") | 4.76mm (0.187") | 0.8mm (0.031") |

| DNMG 150404 | DNMG431 | 15.875mm (0.625") | 4.76mm (0.187") | 0.4mm (0.016") |

| DNMG 150408 | DNMG432 | 15.875mm (0.625") | 4.76mm (0.187") | 0.8mm (0.031") |

| DNMG 150608 | DNMG442 | 15.875mm (0.625") | 6.35mm (0.25") | 0.8mm (0.031") |

| DNMG 190612 | DNMG543 | 19.05mm (0.75") | 6.35mm (0.25") | 1.2mm (0.047") |

Example: DNMG 150608

- Rhombic (diamond) shape with a 55-degree included angle

- 0-degree clearance angle

- Medium tolerance

- Manufacturer-specific chipbreaker and hole configuration

- 15.875mm inscribed circle diameter (approx. 0.625″ in inches)

- 6.35mm thick (approx. 0.25″ in inches)

- 0.8mm nose radius (approx. 0.031″ in inches)

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Carbide inserts are some of the most versatile and durable cutting tools available. But how are they made? And what makes them so strong? In this video, we’ll explore the science behind carbide inserts, from the properties of tungsten carbide to the manufacturing process.

Our Production Capability