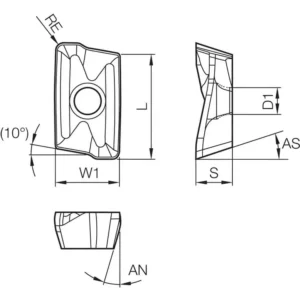

BDMT insert

As a leading supplier of cutting-edge milling solutions, we offer a comprehensive range of BDMT inserts designed for maximum efficiency and durability in large-scale industrial applications. Our products cater to wholesale customers seeking top-quality milling tools for their operations.

BDMT Insert Specification Guide

- B: Typically indicates a specific type or shape of the insert. In the case of BDMT, it often refers to a round or button-shaped insert, though this can vary by manufacturer.

- D: Relief angle.

- M: Indicates the clamping method or the style of the insert, such as a specific mounting or chipbreaker style.

- T: Can indicate the thickness of the insert or other dimensional characteristics.

BDMT Insert Cutter Compatibility

Our inserts are designed to fit a wide range of milling cutters, ensuring versatility across various machining operations:

- Face milling cutters

- Shoulder milling cutters

- High-feed milling cutters

The right BDMT insert cutter combination can significantly enhance your milling efficiency and output quality.

애플리케이션

Inserts excel in various industrial milling operations:

- General face milling

- Shoulder milling

- Roughing and finishing operations

- Suitable for materials including steel, stainless steel, and cast iron

왜 인서트를 선택해야 할까요?

Precision Performance

Our BDMT inserts are engineered for high-precision milling operations, delivering exceptional accuracy and consistent results in CNC machining applications.

Versatile Application

Suitable for a wide range of materials including steel, stainless steel, and cast iron, making them a versatile choice for various machining needs.

Extended Tool Life

Manufactured from premium-grade carbide, our BDMT inserts offer superior wear resistance, reducing the frequency of tool changes and lowering overall tooling costs.

Optimized for CNC Operations

Specially designed to meet the demands of modern CNC machining, offering predictable performance for programmed operations.

소니의 생산 역량