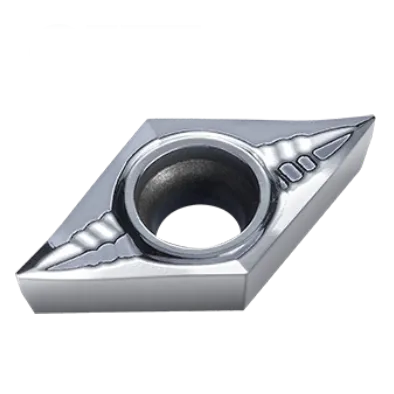

DCGX insert

DCGX insert angle:7° Positive rake insert with a single-sided chipbreaker;

55° rhombic turning insert;

Primary workpiece material: Aluminium;

Breaker application: Semi-finshing and finishing machining;

Matching turning tool holder: SDQCR/L, SDUCR/L;

Material : Tungsten carbide;

DCGX insert specification

G class tolerance with big rake angle, polish and ground on surface, special geometry is resistant to chip built-up on the insert edge, maximize surface finish on aluminum machining and insert tool life.

DCGX insert tool holder

DCGX insert Introduction

Understanding the DCGX Insert Code

- D: Shape: Rhombic (diamond) with a 55-degree included angle.

- C: Clearance Angle: 7 degrees (positive).

- G: Tolerance: “G” indicates a medium tolerance range, though other precision tolerances may exist.

- X: Chipbreaker style & Hole Configuration. This letter designates the specific chipbreaker geometry and whether the insert has a hole or not. Chipbreaker variations are numerous and manufacturer-specific.

-

- Numerical Digits:

- First Two Digits: Inscribed circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

- Next Two Digits: Thickness in millimeters. Divide by 25.4 to convert to inches.

- Last Two Digits: Nose radius in millimeters. To convert to inches, divide by 25.4.

- Numerical Digits:

DCGX Insert Dimensions (ISO)

| ISO 지정 | 각인된 원(IC) | 두께 | 모서리 반경 |

|---|---|---|---|

| DCGX 070202 | 7.94mm (0.313") | 2.38mm (0.094") | 0.2mm (0.008") |

| DCGX 070204 | 7.94mm (0.313") | 2.38mm (0.094") | 0.4mm (0.016") |

| DCGX 11T302 | 11mm (0.433") | 3.18mm (0.125") | 0.2mm (0.008") |

| DCGX 11T304 | 11mm (0.433") | 3.18mm (0.125") | 0.4mm (0.016") |

| DCGX 11T308 | 11mm (0.433") | 3.18mm (0.125") | 0.8mm (0.031") |

Example: DCGX 11T308

- Rhombic (diamond) shape with a 55-degree included angle.

- 7-degree positive clearance angle.

- Medium tolerance.

- Manufacturer-specific chipbreaker and hole configuration.

- 11mm inscribed circle diameter (approx. 0.43″ in inches).

- 3.18mm thick (approx. 0.125″ in inches).

- 0.8mm nose radius (approx. 0.031″ in inches).

카바이드 인서트의 과학: 초경 인서트의 제작 방법과 그토록 강력한 이유

카바이드 인서트는 가장 다재다능하고 내구성이 뛰어난 절삭 공구 중 하나입니다. 하지만 어떻게 만들어질까요? 그리고 그토록 강한 이유는 무엇일까요? 이 동영상에서는 텅스텐 카바이드의 특성부터 제조 공정에 이르기까지 카바이드 인서트의 과학적 원리를 살펴봅니다.

소니의 생산 역량