RPMTがビジネスに最適な理由

卓越した精度と正確さ

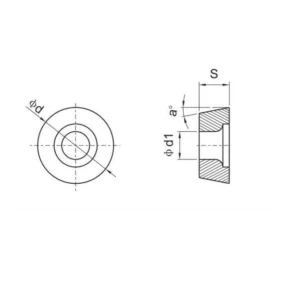

RPMTチップは、機械加工における精密切削と高精度を保証するために、高度な形状で設計されています。その設計は、高品質の結果を得るために必要な正確な仕様と厳しい公差を達成することを保証します。

メリット

- 正確なカットと緻密な仕上がりを実現。

- 手直しや修正の必要性を減らす。

優れた耐久性と寿命

高品質の超硬合金または サーメット 高度なコーティングを施したRPMTインサートは、過酷な条件に耐えるよう設計されています。その耐久性により、工具寿命が延長され、インサート交換回数が減少します。.

メリット

- 高い切削力と温度に耐える。

- 工具の交換とそれに伴うダウンタイムを最小限に抑えます。

多彩なアプリケーション

RPMTチップは汎用性が高く、以下のような幅広い加工に適しています:

- ターニング・オペレーション: 荒加工と仕上げ加工の両方に最適。

- フライス作業: フェースフライス加工、スロット加工、プロファイル加工に有効。

- グルービングとパーティング: 内面および外面溝加工、パーティングオフ加工に適しています。

メリット

- 様々な材料や切断条件に適応。

- 複数のアプリケーションに対応することで、ツール在庫を合理化します。

先端コーティングと材料

RPMTチップには、耐摩耗性と切削性能を向上させるPVD(物理蒸着)やCVD(化学蒸着)などの高品位コーティングが施されています。これらのコーティングは、摩擦を低減し、工具効率を向上させるのに役立ちます。

メリット

- 工具の寿命と性能を向上させる。

- 多様な加工環境において一貫した結果を保証する。

正しいRPMTインサートの選択

適切なものを選択するには RPMTインサート ご応募の際は、以下の点をご検討ください:

- 素材: 加工する材料の種類(スチール、ステンレススチール、鋳鉄など)。

- オペレーション・タイプ 特定の加工操作(旋盤加工、フライス加工、溝加工など)。

- 切断条件: 切削速度、送り速度、切り込み深さなどの要素。

- インサートの形状とコーティング: 必要な性能とアプリケーションのニーズに基づいて選択する。

生産能力