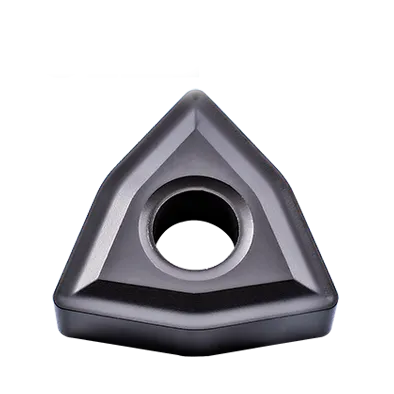

Inserción WNMG

Wnmg Insert Angle : 0° Negative Rake Insert With Double-Sided Chipbreaker;

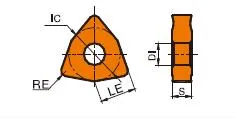

Inserto de Carburo Wnmg Círculo Inscrito (Ic) De 9.525mm/12.7mm, Espesor De 3.97mm/4.76mm, Y Radio De Esquina (Nariz) De 0.2mm/0.4mm/0.8mm/1.2mm;

Escena de mecanizado:Desbaste Mecanizado/Mecanizado de semiacabado/Mecanizado de acabado;

Materiales de la pieza de trabajo: Acero al carbono y aleado, acero inoxidable y aleaciones de alta temperatura, acero y hierro fundido;

A juego Portaplaquitas Wnmg: SWLNR/L, MWWNR/L, DWLNR/L, WWLNR/L, MWMNN, MWLNR/L ;

Tamaños de plaquitas de metal duro Wnmg:(Iso) Wnmg06t304; Wnmg06t308; Wnmg060404; Wnmg060408; Wnmg080404; Wnmg080408; Wnmg080412;

(Ansi) Wnmg331/ Wnmg332/ Wnmg431/ Wnmg432;

Presentación del producto

El inserto WNMG puede hacer frente a múltiples operaciones combinando diferentes rompevirutas y calidades.

Características principales

- Diseño Trigon de doble cara**: Forma de trigono de 80° con seis filos de corte (tres por cara), maximizando la vida útil de la herramienta y la rentabilidad.

- Variedad de radios de punta: Opciones como 0,2 mm, 0,4 mm, 0,8 mm o 1,2 mm para acabado (radios más pequeños) o desbaste (radios más grandes) con mayor resistencia del filo.

- Recubrimientos avanzados**: TiN, TiCN, AlTiN o CVD/PVD (por ejemplo, TiAlN, TiCAN-Al2O3) para mejorar la resistencia al desgaste, reducir la formación de cráteres y prolongar la vida útil de la herramienta.

- Amplios parámetros de corte: Admite profundidades de corte de 1,5-6,0 mm y velocidades de avance de 0,25-0,60 mm/rev, adecuado para desbaste a acabado.

- Rastrillo neutro o positivo: Reduce las fuerzas de corte, evita el astillado y mejora la evacuación de la viruta, especialmente con rompevirutas doble positivo.

Inserto WNMG Especificación

Entender el código WNMG

Las letras y números de la denominación WNMG revelan información crucial:

- W: Forma de trigono con un ángulo incluido de 80

- N: Ángulo de inclinación neutro (0°)

- M: Clase de tolerancia (indica la precisión del tamaño)

- G: Indica el diseño específico del agujero y del rompevirutas (varía según el fabricante)

Números:

- Normalmente, los dos primeros números representan el círculo inscrito (tamaño del triángulo) en dieciseisavos de pulgada (o directamente en milímetros para los códigos ISO).

- El tercer número representa el grosor en dieciseisavos de pulgada.

- El último número suele indicar el radio de la nariz (más pequeño significa más afilado).

Dimensiones de las plaquitas de metal duro WNMG (ISO Y ANSI)

| TAMAÑOS DE INSERTOS WNMG | ||||

|---|---|---|---|---|

| Designación ISO | Designación ANSI | Círculo inscrito (IC) | Espesor | Radio de esquina |

| WNMG 060404 | WNMG331 | 6,35 mm (0,25") | 3,18 mm (0,125") | 0,4 mm (0,016") |

| WNMG 060408 | WNMG332 | 6,35 mm (0,25") | 3,18 mm (0,125") | 0,8 mm (0,031") |

| WNMG060412 | WNMG333 | 6,35 mm (0,25") | 3,18 mm (0,125") | 1,2 mm (0,047'') |

| WNMG 080404 | WNMG431 | 8 mm (0,315") | 4,76 mm (0,187") | 0,4 mm (0,016") |

| WNMG 080408 | WNMG432 | 8 mm (0,315") | 4,76 mm (0,187") | 0,8 mm (0,031") |

| WNMG080412 | WNMG433 | 8 mm (0,315") | 4,76 mm (0,187") | 1,2 mm (0,047'') |

Ejemplo: WNMG 080408 (ISO)

- Forma Trigon, inserto de rastrillo neutro.

- Círculo inscrito de 12,7 mm (aprox. 1/2″).

- Grosor de 4,76 mm (aprox. 3/16″).

- Diseño específico del rompevirutas/agujero.

Preguntas frecuentes

Elija un inserto WNMG en función de:

- Material de la pieza: Adapte la calidad de la plaquita a su material.

- Tipo de operación de giro: El desbaste necesita un radio de nariz mayor para mayor resistencia, el acabado necesita un radio menor para un mejor acabado superficial.

- Control de chip: La elección de la geometría perfecta del rompevirutas es crucial con los WNMG para optimizar el proceso de corte.

Consideraciones importantes

- Insertos WNMG Son increíblemente versátiles, pero la clave para maximizar el rendimiento reside en seleccionar el rompevirutas adecuado para su operación y material específicos. Consulte la documentación del fabricante para obtener más detalles.

La ciencia de las plaquitas de metal duro: Cómo se fabrican y por qué son tan resistentes

Las plaquitas de metal duro son unas de las herramientas de corte más versátiles y duraderas que existen. Pero, ¿cómo se fabrican? ¿Y qué las hace tan resistentes? En este vídeo, exploraremos la ciencia que hay detrás de las plaquitas de metal duro, desde las propiedades del carburo de tungsteno hasta el proceso de fabricación.

Nuestra capacidad de producción

En la fabricación moderna, las plaquitas de metal duro de alto rendimiento son herramientas indispensables que sientan las bases de un procesamiento eficaz y preciso del metal. Sin embargo, estas excepcionales plaquitas no nacen por sí solas, sino que cuentan con el apoyo inquebrantable de una maquinaria avanzada.