Inserción VBGT

VBGT 35 degree insert angle: 5° Positive Rake Insert with single-sided Chipbreaker;

Screw-On Insert, finishing geometry with high positive rake face for chip control in long chipping materials.

Breaker Application: Finshing machining

Matching TurningTool Holder: SVQCR/L, SVUCR/L, SVQBR/L, SVUBR/L

Range of VBGT insert types:VBGT1103/VBGT1604

VBGT Insert can deal with multiple operations by combining different chip breakers and grades.

Material : Carburo de Tungsteno;

Product Introduction

The VBGT insert is specially designed for aluminum alloy lathe machining, with a dedicated chipbreaker, which not only eliminates the problem of chip entanglement that occurs during aluminium alloy finishing, but also provides an excellent surface finish.

Key Features of VBGT Inserts

- 80° Rhombic Shape: Provides four cutting edges and strength for general purpose turning.

- Positive Rake Angle: This can offer a slightly smoother cut and lower cutting forces compared to negative rake inserts.

- Chipbreaker Options: VBGT inserts feature various chipbreaker designs for influencing chip flow during specific operations.

- Coatings: Often coated with TiN, TiCN, AlTiN, etc., for improved wear resistance.

VBGT insert Specification

Here’s a breakdown of VBGT insert specifications, including the code meaning and important features:

VBGT Designation

- V: 80° rhombic shape. This offers stability and strength for varied turning operations.

- B: 5° relief angle (clearance angle).

- G: Chipbreaker type and hole design (varies between manufacturers).

- T: Indicates a tolerance class for precision of inscribed circle and thickness.

Common VBGT Dimensions

VBGT inserts, like many others, have numbers that determine their size:

VBGT 110X0X:

- Inscribed Circle (IC): 0.125″ (1/8″)

- Thickness: 0.094″ (3/32″)

- X represents the nose radius (e.g., 1 = 1/64″, 0 = sharper corner)

VBGT 160X0X:

- Inscribed Circle (IC): 0.625″ (5/8″)

- Thickness: 0.125″ (1/8″)

- X represents the nose radius

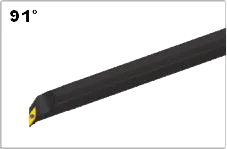

VBGT insert holder

SVQBR/L

SVUBR/L

Carbide VBGT Insert Dimensions (ISO and ANSI)

| Designación ISO | Círculo inscrito (IC) | Espesor | Radio de esquina |

|---|---|---|---|

| VBGT 110302 | 11mm (approx. 0.43") | 3.18mm (1/8") | 0.2mm (approx. 0.008") |

| VBGT 110304 | 11mm (approx. 0.43") | 3.18mm (1/8") | 0.4mm (approx. 0.016") |

| VBGT 160404 | 16mm (approx. 0.63") | 4.76mm (3/16") | 0.4mm (approx. 0.016") |

| VBGT 160408 | 16mm (approx. 0.63") | 4.76mm (3/16") | 0.8mm (approx. 0.031") |

Example: VBGT 110302 (ISO)

- 80° rhombic shape, positive rake insert.

- Inscribed circle of 6.35mm (approx. 1/4″).

- Thickness of 3.18mm (approx. 1/8″).

- Specific chipbreaker/hole design.

La ciencia de las plaquitas de metal duro: Cómo se fabrican y por qué son tan resistentes

Las plaquitas de metal duro son unas de las herramientas de corte más versátiles y duraderas que existen. Pero, ¿cómo se fabrican? ¿Y qué las hace tan resistentes? En este vídeo, exploraremos la ciencia que hay detrás de las plaquitas de metal duro, desde las propiedades del carburo de tungsteno hasta el proceso de fabricación.

Nuestra capacidad de producción