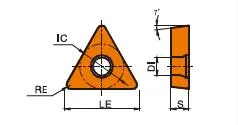

Inserto TCMT

TCMT insert angle: 7° Positive Rake Insert with Chipbreaker;The center hole is a 40°-60° single countersink;

TCMT insert inscribed circle (IC) of 6.35mm/9.525mm, thickness of 2.38mm/3.97mm, and corner (nose) radius of 0.4mm/0.8mm/1.2mm;

Screw-On Insert, Semi-finishing geometry with high positive rake face for chip control in long chipping materials;

60°Triangle carbide insert; And a single-sided chip breaker;

Breaker Application: Semi-finshing machining;

Matching TCMT insert Holder: STFCR/L, STGCR/L, STTCR/L;

Range of TCMT insert types: (ISO)TCMT110204/TCMT16T3/TCMT0902/;(ANSI)TCMT32.51/TCMT21.51;

TCMT Insert can deal with multiple operations by combining different chip breakers and grades;

Material : Carburo de Tungsteno;

Product Introduction

TCMT insert meaning refers to a triangular-shaped turning insert with a 60-degree included angle (T), a 7-degree clearance angle (C), a medium tolerance class (M), and usually a chipbreaker feature (T).

These inserts offer three cutting edges and a positive rake angle, making them suitable for finishing and semi-finishing operations on smaller workpieces or softer materials.

Their design prioritizes achieving a good surface finish while the chipbreaker ensures effective chip control.

TCMT inserts are a versatile and cost-effective choice for many general-purpose turning applications.

TCMT insert Specification

TCMT meaning:

- T: Trigon or triangular shape with a 60-degree included angle.

- C: 7-degree clearance angle (creates space between the cutting edge and workpiece).

- M: Medium tolerance class (a general-purpose range of precision).

- T: Single-side chipbreaker and screw lock.

Following the “TCMT” you’ll see a set of numbers, such as TCMT 21.51 or TCMT 32.52. These numbers tell you the size:

- First number (2 or 3): Indicates the cutting edge length in sixteenths of an inch.

- Number after decimal (1.5 or 2.5): Thickness of the insert in sixteenths of an inch.

- Final number (0, 1, or 2): Nose radius code. A smaller number means a sharper corner, ideal for finishing work.

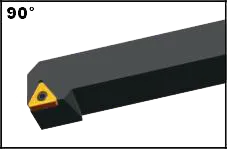

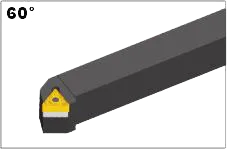

TCMT insert holder

STGCR/L

STTCRL

TCMT carbide Insert Dimensions (ISO and ANSI)

| TCMT Designation | Círculo inscrito (IC) | Espesor | Radios de esquina comunes |

|---|---|---|---|

| TCMT 21.51 (0602) | 6.35mm (approx. 0.25") | 2.38mm (approx. 0.094") | 0.4mm (0.015"), 0.8mm (0.031") |

| TCMT 32.51 (1103) | 9.525mm (approx. 0.375") | 4mm (approx. 0.156") | 0.4mm (0.015"), 0.8mm (0.031"), 1.2mm (0.047") |

Example: TCMT 32.52

- Triangular shape

- 7° side clearance angle

- Moderate manufacturing precision

- Some sort of hole and chipbreaker design

- 3/16″ cutting edge length

- 5/32″ thickness

- Nose radius of 0.0625″ (1/16″) – best for general purpose or roughing cuts

La ciencia de las plaquitas de metal duro: Cómo se fabrican y por qué son tan resistentes

Las plaquitas de metal duro son unas de las herramientas de corte más versátiles y duraderas que existen. Pero, ¿cómo se fabrican? ¿Y qué las hace tan resistentes? En este vídeo, exploraremos la ciencia que hay detrás de las plaquitas de metal duro, desde las propiedades del carburo de tungsteno hasta el proceso de fabricación.

Nuestra capacidad de producción