Fresa de desbaste

Las fresas de desbaste se utilizan principalmente en las fases iniciales del mecanizado, centrándose en la eliminación rápida de material para acercar la pieza a su forma final. Sus aplicaciones abarcan varias industrias y procesos de fabricación.

Fresa de desbaste Aplicación

Aplicaciones comunes:

- Fabricación de moldes y matrices: Creación de cavidades y formas iniciales.

- Industria del automóvil: Mecanizado de bloques de motor, piezas de transmisión y otros componentes.

- Aeroespacial: Procesamiento de grandes piezas metálicas para aviones y naves espaciales.

- Mecanizado general: Eliminación del material sobrante de las piezas antes de las operaciones de acabado.

Operaciones específicas de mecanizado:

- Hogging: Eliminación rápida de grandes cantidades de material.

- Ranurado: Creación de ranuras o surcos en la pieza.

- Bolsillo: Fresado de bolsas o cavidades.

- Contorneado: Desbaste de la forma básica de una pieza.

Fresa de desbaste Características

Geometría de los dientes

- Diseño agresivo de los dientes: Presenta dientes más grandes y más espaciados en comparación con las fresas de acabado.

- Perfil del diente ondulado o dentado: Rompe eficazmente las virutas, reduciendo las fuerzas de corte y evitando la acumulación de virutas.

Diseño de flautas

- Flautas más profundas: Acomodan cargas de virutas más grandes y mejoran la evacuación de las virutas.

- Diseño de flauta en espiral: Mejora el arranque de virutas y reduce las fuerzas de corte.

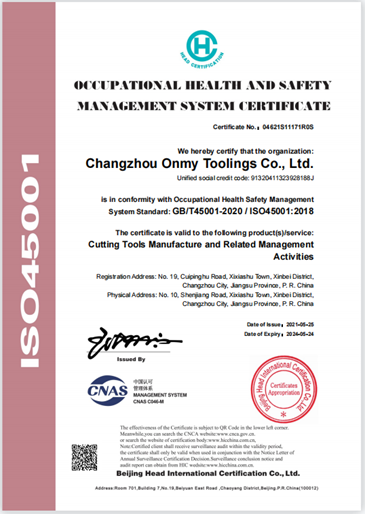

Material y revestimiento

- Materiales más resistentes: Fabricadas en acero rápido (HSS) o metal duro para soportar condiciones de corte duras.

- Revestimientos protectores: A menudo se aplica para mejorar la resistencia al desgaste, la resistencia al calor y la vida útil de las herramientas.

Diseño general

- Diámetro mayor: Permite mayores velocidades de arranque de material.

- Longitud de flauta más corta: Proporciona mayor rigidez y reduce las vibraciones.

ULTRA MICRO GRAIN CARBIDE& NANO GRAIN CARBIDE

Materiales de sustrato de metal duro de primera calidad que ofrecen una excepcional resistencia al desgaste, lo que permite un mecanizado de alta precisión.

DISEÑO ESPECIALIZADO DECORNER GASH

- El diseño exclusivo de las estrías y la protección superior de las esquinas aumentan tanto la vida útil de la herramienta como la protección contra fallos catastróficos en aplicaciones de alto avance.

- Estrías pulidas para un excelente flujo de viruta.

SOLICITUD

Adecuado para procesar metales no ferrosos de dureza más blanda, como aleaciones de aluminio, cobre, zinc, magnesio, etc.

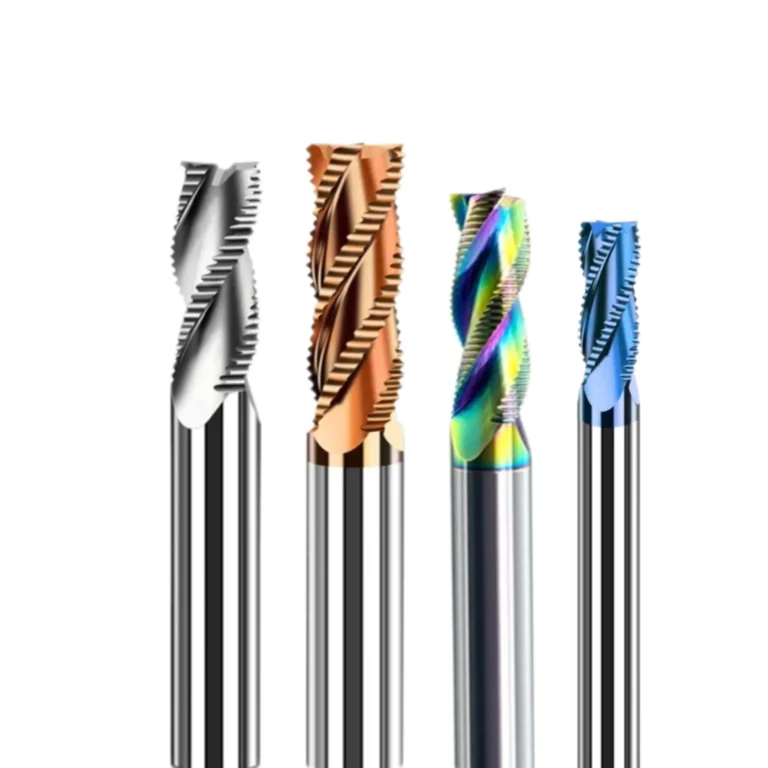

Competidor (longitud total de corte: 180 m)

Fresas ONMY (Longitud total de corte: 300m)

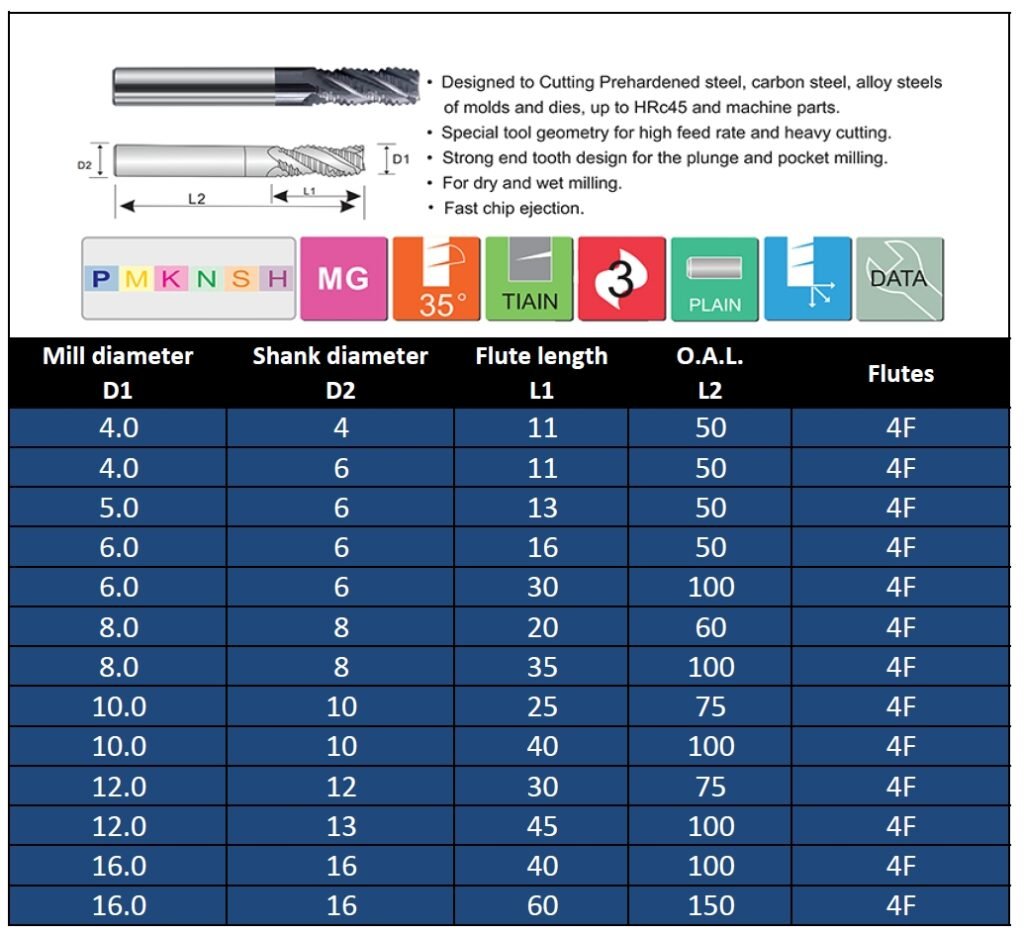

Catálogo de fresas de desbaste

La diferencia de ONMY TOOLINGS

¿Qué distingue a nuestro fresa de un solo filo ¿Qué nos diferencia? Nuestra combinación única de:

Formulaciones avanzadas de carburo

Utilizamos mezclas patentadas de carburo de micrograno optimizadas para ofrecer solidez y resistencia al desgaste.

Geometrías innovadoras

Nuestros diseños de estrías patentados maximizan la evacuación de virutas y minimizan las fuerzas de corte.

Recubrimientos de vanguardia

Aplicamos revestimientos de PVD con nanocapas que mejoran la resistencia al calor y reducen la fricción.

Rectificado de precisión

Nuestras rectificadoras CNC multieje alcanzan tolerancias tan ajustadas como ±0,0005 pulgadas.

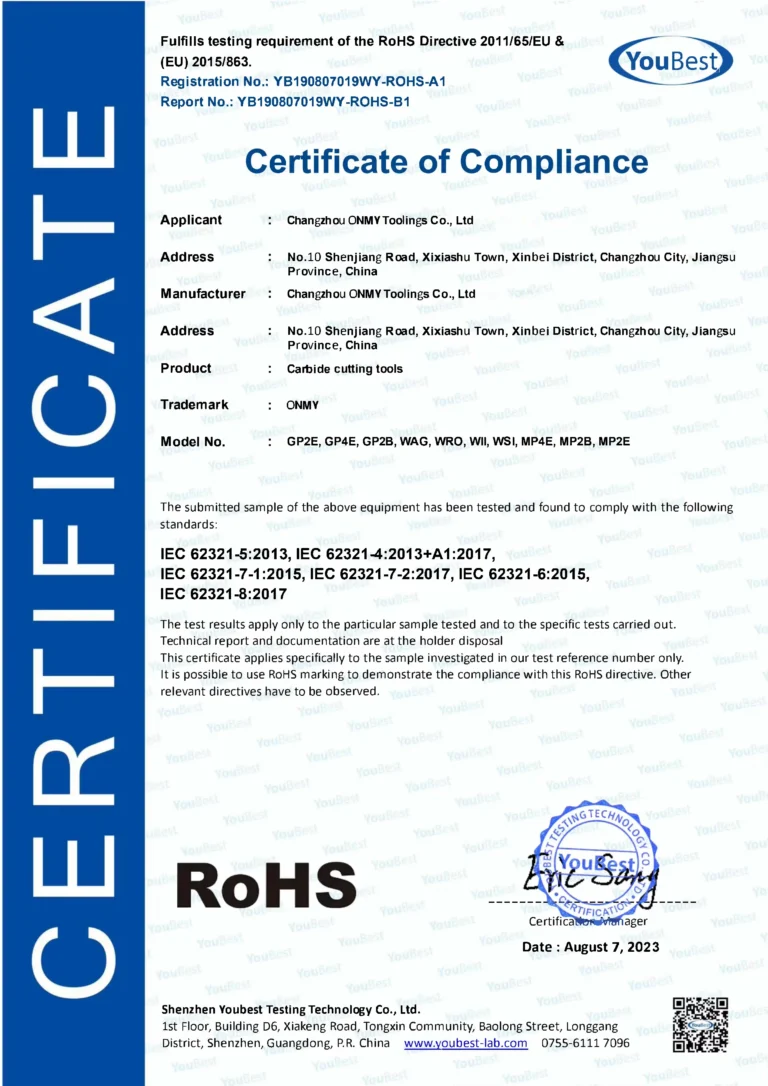

Certificación de fábrica

Estas certificaciones no son meras insignias: son la garantía de una calidad constante y de primer nivel en todas las herramientas que producimos. Nuestro proceso de control de calidad incluye la inspección 100% de dimensiones críticas y pruebas avanzadas de resistencia al desgaste para garantizar que cada herramienta cumple nuestros exigentes estándares.

Nuestro viaje a la excelencia

Nuestra historia comenzó en un pequeño taller con un gran sueño: crear las mejores fresas de punta de toro del mundo. En la actualidad, contamos con unas modernas instalaciones de 50.000 pies cuadrados equipadas con lo último en tecnología de rectificado CNC y avanzados sistemas de recubrimiento. Pero nuestra verdadera fuerza reside en nuestro equipo de apasionados ingenieros y expertos artesanos que vuelcan su experiencia en cada herramienta que producimos.

¿Por qué conformarse con soluciones estándar cuando puede disponer de fresas de mango personalizadas adaptadas a sus necesidades específicas? Nuestro equipo interno de investigación y desarrollo está constantemente ampliando los límites de lo que es posible en tecnología de mecanizado. Colaboramos con las principales universidades y socios industriales para mantenernos a la vanguardia de la ciencia de los materiales y el diseño de herramientas de corte.

No se fíe sólo de nuestra palabra. Esto es lo que dicen nuestros clientes satisfechos:

Mi cliente feliz

Obtenga ahora su presupuesto personalizado

P.D. ¿Le hemos dicho que ofrecemos descuentos por volumen? Cuantos más pedidos haga, más ahorrará.

- Precios directos de fábrica imbatibles: Elimine a los intermediarios y ahorre hasta 40% en comparación con los precios al por menor. Nuestro eficiente proceso de fabricación nos permite ofrecer la máxima calidad a precios competitivos.

- Entrega rapidísima: Gracias a nuestro proceso de producción racionalizado, ofrecemos plazos de entrega líderes en el sector. Obtenga sus fresas personalizadas en tan solo 7 días. Mantenemos un amplio inventario de tamaños estándar para su envío inmediato.

- Servicio personalizado: Nuestro equipo de ingenieros expertos está listo para ayudarle a encontrar la solución perfecta para sus desafíos de mecanizado únicos. Ofrecemos consultas gratuitas para analizar sus necesidades específicas y recomendarle las especificaciones de herramienta ideales.

Preguntas frecuentes

Una fresa de desbaste se utiliza principalmente para eliminar rápidamente grandes cantidades de material de una pieza de trabajo. Está diseñado para ser eficaz en las fases iniciales del mecanizado, en las que el objetivo es dar forma a la pieza para obtener una aproximación del producto final.

Sí., fresas de desbaste Se puede utilizar para el mecanizado de alta velocidad (HSM), pero hay que tener en cuenta algunas consideraciones.

Aunque tradicionalmente se han diseñado para la eliminación de material pesado a velocidades más bajas, los avances en la tecnología de herramientas han producido fresas de desbaste optimizadas específicamente para HSM. Estas herramientas se caracterizan por:

- Geometría del diente optimizada: Diseñada para manejar velocidades de corte más altas y producir virutas más pequeñas.

- Evacuación mejorada de las virutas: Eliminación eficaz de virutas a altas velocidades de avance.

- Revestimientos avanzados: Mejora de la vida útil y el rendimiento de las herramientas en condiciones HSM.

Sin embargo, es crucial seleccionar la fresa de desbaste adecuada para su aplicación específica de HSM. Factores como el material, las capacidades de la máquina y el acabado superficial deseado influirán en la elección de la herramienta.

Una fresa de desbaste es una herramienta de corte diseñada para eliminar rápidamente grandes cantidades de material de una pieza de trabajo. Se ha diseñado específicamente para ser eficaz en las fases iniciales del mecanizado, en las que el objetivo es dar forma a la pieza para obtener una aproximación del producto final.

Características principales de una fresa de desbaste:

- Geometría agresiva del diente: Diseñado para romper eficazmente las virutas y reducir las fuerzas de corte.

- Mayores cargas de virutas: Capaz de manejar cargas de corte más pesadas en comparación con las fresas de acabado.

- Acabado superficial más rugoso: Produce una superficie menos refinada en comparación con las fresas de acabado.

Fresa de desbaste

- Propósito: Elimina rápidamente grandes cantidades de material de una pieza de trabajo.

- Diseño: Geometría agresiva del diente, mayores cargas de viruta, avances más rápidos.

- Resultado: Acabado superficial rugoso.

Fresa de acabado

- Propósito: Consigue un acabado liso de la superficie de la pieza.

- Diseño: Dientes más pequeños y afilados, menores cargas de viruta, avances más lentos.

- Resultado: Acabado superficial liso.

En esencia:

- Fresas de desbaste se utilizan para aproximar la pieza a sus dimensiones finales.

- Fresas de acabado para conseguir la calidad superficial y las tolerancias deseadas.

Ventajas del uso de fresas de desbaste:

- Ahorro de tiempo: La rápida eliminación de material reduce el tiempo de mecanizado.

- Vida útil de la herramienta: Menor desgaste de la herramienta de corte en comparación con el uso de una fresa de acabado para el desbaste.

- Rentable: Costes de eliminación de material optimizados.

- Mejora de la fiabilidad del proceso: Resultados uniformes gracias al diseño especializado de las herramientas.

Aunque la compra de fresas de desbaste supone una inversión inicial, los beneficios a largo plazo suelen compensar el coste. Utilizando la herramienta adecuada para cada trabajo, puede mejorar la eficiencia general del mecanizado y reducir los costes de producción.