硬質合金刀片如何製造:全面的製造指南

硬質合金刀片是現代製造業中不可或缺的零件,因其超高的硬度、耐磨性以及在極端條件下仍能保持鋒利切削刃的能力而備受推崇。但您有沒有想過這些重要的工具是如何製造出來的?在這份全面的指南中,我們將探討硬質合金刀片從原料到成品的複雜製造過程。

簡介:硬質合金刀片的世界

硬質合金刀片為金屬加工產業帶來了革命性的改變,使切削速度更快、表面光潔度更佳、刀具壽命更長。為了瞭解它們的重要性,我們必須先深入了解這些高性能切削工具的複雜製造過程。那麼,硬質合金刀片是如何製造出來的呢?讓我們來探索這個從粉末到精密的奇妙旅程。

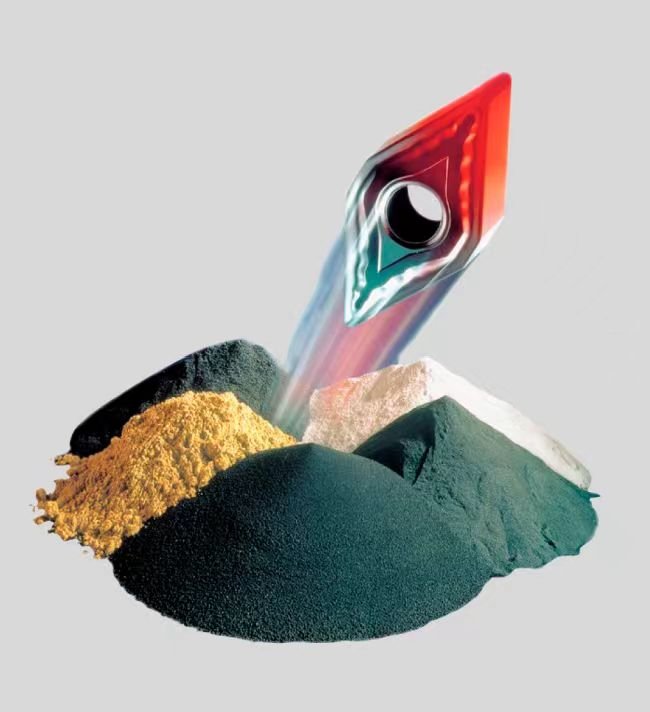

原材料:硬質合金刀片的基礎材料

在回答硬質合金刀片是如何製成的這個問題之前,我們必須先了解相關的材料。製造硬質合金刀片時所使用的主要零件有:

- 碳化鎢粉末:主要成分,提供刀片的硬度與耐磨性。

- 鈷粉:作為黏合劑,將碳化鎢微粒固定在一起。

- 額外 碳化物:例如碳化鈦或碳化鉭,可加入以增強特定特性。.

這些原料的品質和比例會顯著影響硬質合金刀片的最終性能。

製造過程:硬質合金刀片的製造步驟

現在,讓我們深入討論我們的主題:硬質合金刀片是如何製成的?製造過程包含數個關鍵步驟,每個步驟都會影響刀片的最終特性和性能。要瞭解製造這種高性能切削工具的複雜性與精密度,了解這個製程是關鍵。

1.粉末製備

硬質合金刀片的製造過程始於粉末的精心挑選與準備。

- 原料選擇:採購高純度的碳化鎢和鈷粉。這些原料的品質對刀片的最終性能至關重要。

- 粉末分析:對粉末進行粒度分佈、純度和化學成分分析。

- 稱重與配比:根據所需的等級規格,精密稱量碳化鎢和鈷粉末。鈷含量通常從 6% 到 30% 不等,視刀片的預期應用而定。

- 添加劑:如有需要,可在此階段加入碳化鈦或碳化鉭等額外的碳化物,以增強特定的特性。

2.混合與研磨

此步驟對於硬質合金刀片的製作方式至關重要,因為它決定了最終成品的均勻性。

- 初步混合:將測量好的粉末在 V 型攪拌器或渦輪攪拌器中徹底混合,以確保所有成分均勻分佈。

- 球磨:然後將混合物轉移至球磨機。此裝置使用堅硬耐磨的球(通常由碳化鎢製成)進一步混合並研磨粉末。

- 濕磨:加入液態介質,通常是酒精,以促進磨製過程並防止氧化。

- 研磨時間:研磨過程可持續 24 到 72 小時,視所需的顆粒大小和等級特性而定。

- 顆粒尺寸縮小:在碾磨過程中,粉末顆粒會縮小至亞微米尺寸,通常在 0.5 到 5 微米之間。

- 乾燥:研磨後,使用噴霧乾燥或真空乾燥技術將漿料乾燥,以去除液態介質。

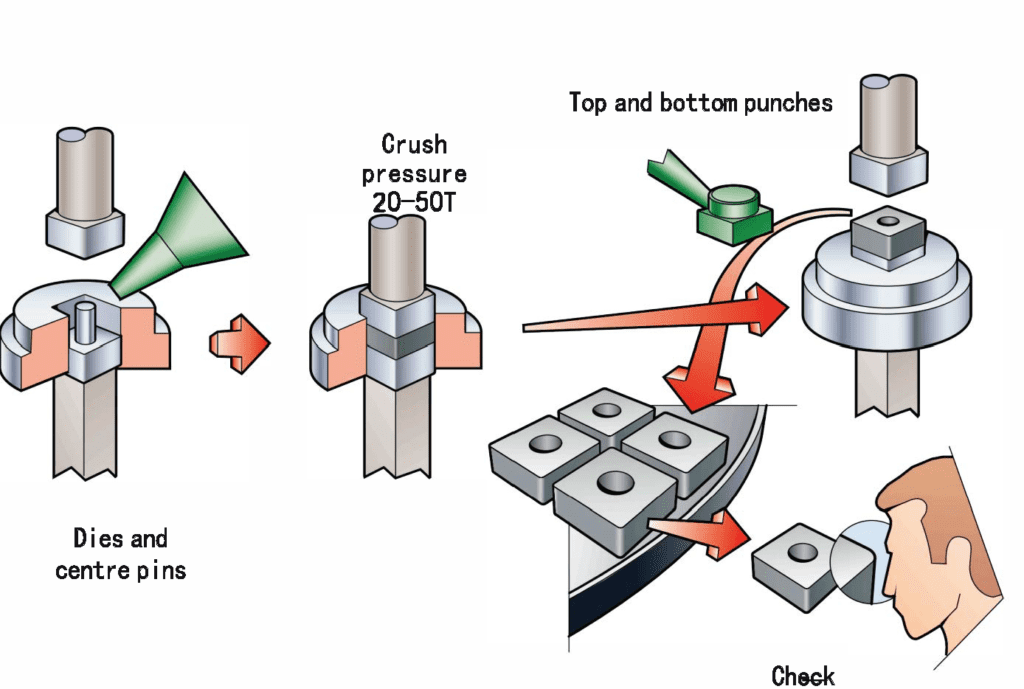

3.擠壓成型

製造硬質合金刀片的下一步是將粉末成型為所需的形狀。

- 粉末潤滑:在粉末中加入少量有機黏合劑(通常是石蠟),以改善其流動性和可壓性。

- 模具準備:製備所需嵌件形狀的模具。模腔通常會稍微大一些,以計算燒結過程中的收縮。

- 粉末填充:小心地將準備好的粉末混合物倒入模腔。

- 壓實:使用液壓機或機械壓縮機在高壓下壓縮粉末,壓力通常在每平方英寸 10 到 30 噸之間。

- 綠色緊實成型:結果是 「綠色壓實」,它具有最終嵌件的基本形狀,但仍相對較軟且易碎。

- 彈出:從模具中小心地彈出綠色 compact。

4.預燒結(可選)

有些製造商在製造硬質合金刀片時,會加入預燒結步驟。

- 低溫加熱:將綠色緊密型加熱至 500°C 至 900°C 的溫度。

- 去除粘合劑:此製程可去除壓榨階段使用的有機黏合劑。

- 強度增加:預燒結可輕微增加壓制品的強度,使其在後續步驟中更容易處理。

5.燒結

燒結是硬質合金刀片製造過程中的關鍵步驟,可將脆弱的綠色緊實材料轉變為致密堅硬的硬質合金刀片。

- 裝爐:生坯(或預燒結部件)被裝入燒結爐。

- 氣氛控制:爐內氣氛需小心控制,通常使用真空或惰性氣體 (如氬氣) 來防止氧化。

- 溫度上升:溫度逐漸升高至 1400°C 左右(接近鈷的熔點)。

- 保持期:溫度維持一段特定時間,通常為 1-3 小時,讓鈷熔化並在碳化鎢微粒之間流動。

- 液相燒結:熔融鈷作為黏合劑,填滿碳化物顆粒之間的空間。

- 冷卻:爐子緩慢冷卻,讓鈷凝固並將碳化物顆粒結合在一起。

- 收縮:在燒結過程中,由於孔隙的消除和結構的鞏固,嵌件會收縮約 17-25%。

6.熱等靜壓 (HIP) (選購)

有些高性能的刀片在製造硬質合金刀片時,還需要經過額外的步驟。

- 高壓環境:燒結的刀片被放置在充滿惰性氣體的特殊腔體中,壓力非常高(高達 30,000 psi)。

- 升溫:腔體加熱至接近燒結溫度。

- 消除孔隙:結合高壓與溫度,消除所有剩餘的孔隙,形成完全致密的結構。

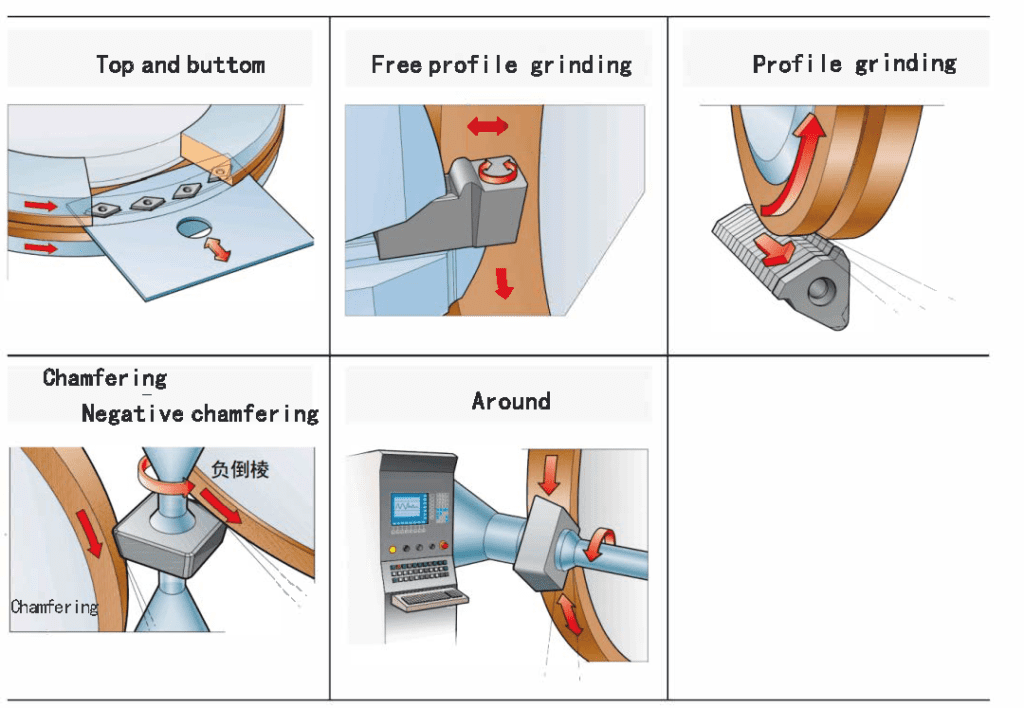

7.精加工和研磨

硬質合金刀片製造的最後步驟是達到最佳性能所需的精確尺寸和幾何形狀。

- 粗研磨:燒結刀片經過研磨,以去除任何表面瑕疵並達到基本形狀。

- 精密研磨:使用高精密研磨機製造特定刀片類型所需的精確尺寸、切削刃及斷屑槽。

- 刃口處理:切削刃可以經過珩磨或特定的微觀幾何形狀來增強其性能和耐用性。

- 表面處理:有些刀片需要經過額外的表面處理,例如拋光,以改善切屑的流動性或減少夾邊的形成。

8.品質控制

在製造硬質合金刀片的整個過程中,都會實施品質控制措施:

- 尺寸檢查:進行精確的量測,以確保嵌入件符合所需的規格。

- 硬度測試:測試刀片的硬度,以確認其符合等級要求。

- 微觀結構分析:在顯微鏡下檢查樣品,以驗證晶粒結構和成分。

- 性能測試:每一批次的部分刀片可能會進行切削測試,以驗證其性能。

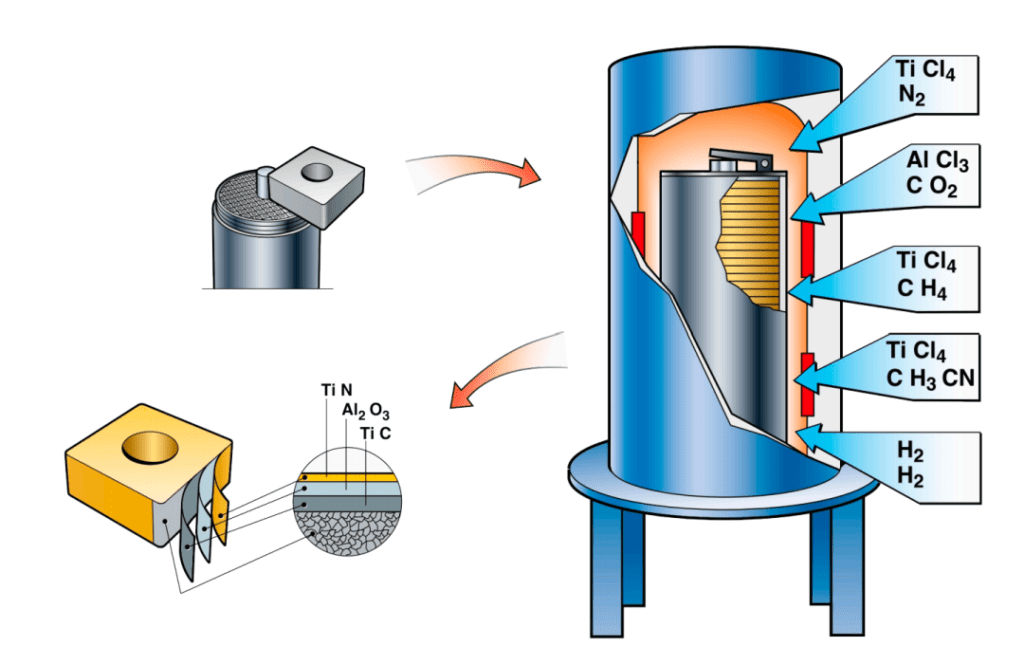

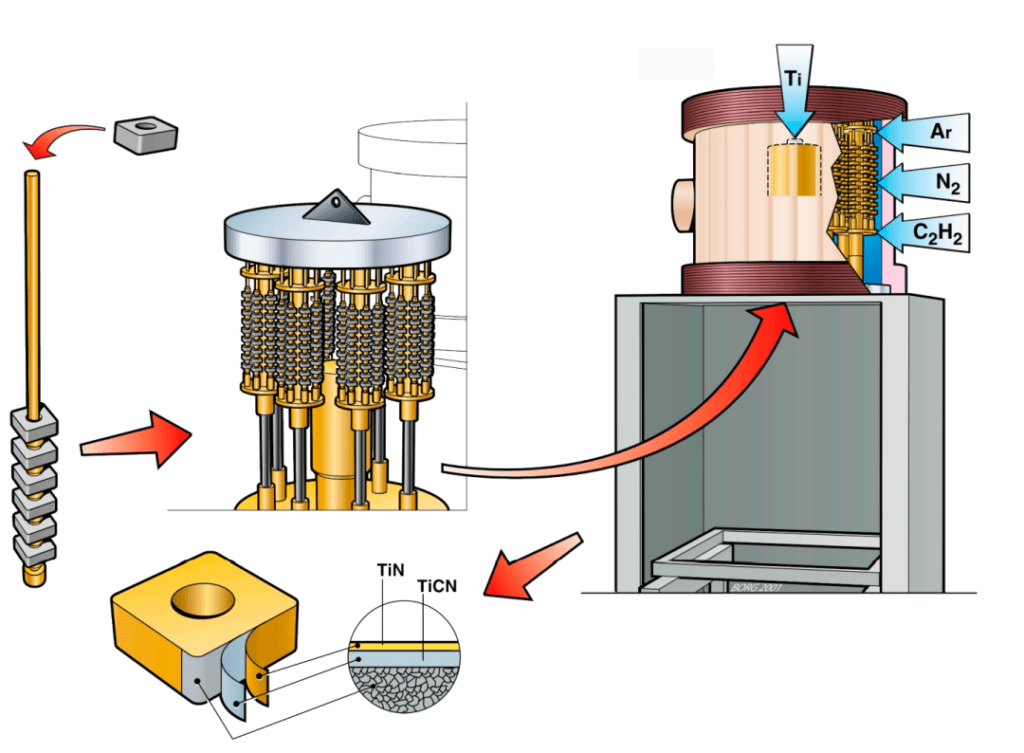

9.塗層(可選)

許多硬質合金刀片在製造過程中還需要經過一個額外的步驟:鍍層。此步驟可增強刀片的耐磨性、熱穩定性及整體性能。

- 表面處理:刀片經過清潔,有時還會進行預處理,以確保良好的塗層附著性。

- 塗層應用:根據所需的屬性,塗層的應用方法包括:

- 化學氣相沉積 (CVD):用於更厚、更耐磨的塗層

- 物理氣相沉積 (PVD):用於更銳利的邊緣和更堅硬的塗層

- 多層塗層:許多現代化的刀片都會使用多層不同的塗層材料來優化性能。

- 鍍膜後處理:有些鍍膜刀片需要經過額外的處理,例如邊緣珩磨或拋光,以精緻鍍膜表面。

了解硬質合金刀片製造的詳細過程,可突顯製造這些重要切削工具的複雜性與精密度。每個步驟都會影響刀片的最終特性,以確保它能承受現代加工的嚴苛條件。

塗層技術:增強硬質合金刀片性能

許多硬質合金刀片在製造過程中還需要經過一個額外的步驟:塗層。但什麼是硬質合金刀片上的塗層,以及為何要進行塗層?

塗層是在硬質合金刀片表面塗上一層薄薄的硬質材料,以增強其性能。常見的塗層材料包括

- 氮化鈦 (TiN)

- 碳氮化鈦 (TiCN)

- 氧化鋁 (Al2O3)

- 氮化鈦鋁 (TiAlN)

這些塗層通常使用以下方法進行塗裝:

- 化學氣相沉積 (CVD)

- 物理氣相沉積 (PVD)

塗層製程是製造硬質合金刀片的重要一環,適用於許多高性能的應用。它可以顯著改善耐磨性、降低摩擦並延長刀具壽命。

硬質合金刀片等級與分類

要瞭解硬質合金刀片的製造過程,也必須瞭解不同等級的硬質合金刀片。硬質合金刀片的等級系統對於選擇適合特定加工應用的刀具是非常重要的。讓我們深入探討硬質合金刀片技術中這個複雜但重要的層面。

ISO 分類系統

國際標準化組織 (ISO) 已經建立了一套廣為接受的硬質合金刀片分類系統。此系統使用字母及數字來表示刀片的特性及用途:

- 申請群組 (信件):

- P:用於加工鋼材(藍色代碼)

- M:用於加工不銹鋼(黃色代碼)

- K: 用於加工鑄鐵(紅色代碼)

- N:用於加工非鐵金屬(綠色代碼)

- S:用於加工耐熱超合金和鈦(棕色色標)

- H:用於加工硬化材料(灰色色碼)

- 硬度與韌性等級表 (數字):

- 範圍從 01 到 50

- 較低的數字表示較硬、較耐磨的等級 (例如 P01、K10)

- 較高的數字表示更堅硬、更耐衝擊的等級 (例如 P50、M40)

特定等級特性

在每個應用程式群組中、, 硬質合金刀片等級 可根據其組成和特性進一步區分:

- C 等級(鑄鐵):

- 範例:K10 - 用於高速鑄鐵精加工的細粒度 WC-Co 牌號

- 範例:K20 - 一般用途鑄鐵加工的中粒度等級

- P 等級(鋼):

- 範例:P01 - 用於鋼材高速精加工的超細晶粒等級

- 範例:P25 - 中等晶粒等級,具有良好的耐磨性與韌性平衡,適用於一般鋼材加工

- M 等級(不銹鋼):

- 範例:M10 - 適用於不銹鋼高速加工的細粒度等級

- 範例:M30 - 用於不銹鋼斷續切削的更高強度等級

- 專業等級:

- 用於有色金屬材料(如鋁、銅)的 N 等級

- 耐熱超合金的 S 牌號(例如:Inconel、Hastelloy)

- 用於硬化鋼和其他硬質材料的 H 牌號

微觀結構與成分

硬質合金刀片的等級與其製造方式直接相關。主要因素包括:

- 顆粒大小:

- 奈米級晶粒:<0.1 μm

- 次微米:0.1-0.5 μm

- 細粒度:0.5-1.0 μm

- 中顆粒:1.0-2.5 μm

- 粗粒度:>2.5 微米

- 鈷含量:

- 通常範圍從 6% 到 30%

- 較高的鈷含量會增加韌性,但會降低硬度

- 額外的碳化物:

- 碳化鈦 (TiC):改善火山口耐磨性

- 碳化鉭 (TaC):增強高溫穩定性

- 碳化鈮 (NbC):增加邊緣強度

選擇合適的等級

選擇適當的硬質合金刀片等級需要考慮幾個因素:

- 工件材料:將刀片等級與加工材料相匹配。

- 切削條件:考慮切削速度、進給率和切削深度等因素。

- 機器穩定性:穩定性較高的機器可以使用較硬的材質;穩定性較低的機器可能需要較硬的材質。

- 表面光潔度要求:粒度較細的等級通常會產生較好的表面光潔度。

- 刀具壽命期望:在連續切削作業中,硬度較高的材質通常可提供較長的刀具壽命。

先進等級開發

隨著製造商不斷改良硬質合金刀片的製造方式,新的等級也被開發出來以因應特定的挑戰:

- 多層級:將不同的碳化物成分結合成層,以優化性能。

- 功能分級刀片:從核心到表面的成分各不相同,以達到韌性與耐磨性的理想平衡。

- 奈米複合材質等級:加入奈米尺寸的顆粒以增強特定特性。

瞭解這些等級和分類對於優化加工流程至關重要。透過選擇正確的等級,製造商可以大幅提高生產力、刀具壽命及零件品質。當我們繼續探索硬質合金刀片是如何製造出來的時候,很明顯的,在將製造過程轉換成實用的、針對特定應用的工具時,等級系統扮演了舉足輕重的角色。

硬質合金刀片與陶瓷刀片:比較

當我們專注於硬質合金刀片的製造過程時,值得將它與另一種熱門的選擇:陶瓷刀片進行比較。

硬質合金刀片提供:

- 更佳的韌性與耐衝擊性

- 更廣泛的應用範圍

- 成本較低

陶瓷插入件提供:

- 更高的耐熱性

- 高切削速度下性能更佳

- 在某些應用中可延長刀具壽命

硬質合金和陶瓷的選擇取決於特定的加工需求和工件材料。

瞭解硬質合金刀片標記

要了解硬質合金刀片的製造過程,必須先瞭解刀片上的標記。硬質合金刀片上的標記提供了關於其幾何形狀、尺寸及預期應用的重要資訊。這些標記遵循標準化的系統,主要是業界廣泛使用的ISO(國際標準化組織)系統。讓我們來分解這些標記,以瞭解每個元素所代表的意義。

ISO 命名系統

ISO 系統使用一系列字母和數字來描述插入物的特性。典型的 ISO 指定可能如下所示:

CNMG 120408-PM 4325

讓我們逐步解碼這個標記:

- 插入形狀(第 1 個字母)

- C: 80° 鑽石

- D:55° 鑽石

- R:圓形

- S: 正方形

- T: 三角形

- V:35° 鑽石

- W: Trigon (三面)

- 浮雕角度 (第 2 個字母)

- N: 0°

- P: 11°

- C: 7°

- E: 20°

- F: 25°

- O:0°(針對特定應用)

- 寬容班 (第 3 個字母)

- A: 最接近的公差

- G: 中等容忍度

- M:更寬的容忍度

- 插入功能(第 4 個字母)

- G: 在面上開槽,孔用锪孔

- N: 在面上開槽,孔不含沉孔

- R: 不含沉孔的圓孔

- T: 有沉孔,無凹槽

- 插入尺寸(第一組數字)

- 12:刻圓直徑或邊緣長度(以 mm 為單位)

- 04:插件厚度(以 mm 為單位)

- 轉角半徑(最後兩位數字)

- 08: 0.8 mm 轉角半徑

- 斷屑機及研磨機 (-PM 4325)

- PM:斷路器型式(因製造商而異)

- 4325:等級指定(因製造商而異)

附加標記

除了 ISO 系統之外,製造商通常還會加入其他標記:

- 品牌標誌:識別製造商。

- 材料等級:通常以顏色標示(如藍色代表鋼,黃色代表不銹鋼)。

- 塗層類型:可用特定顏色或標記表示。

- 切削刃狀況:符號可能表示磨光或銳利的邊緣。

- 冷卻孔指示器:適用於刀片設計,可通過刀具冷卻。

解釋特殊幾何圖形

有些刀片有特殊的幾何形狀,會在其標記中指出:

- 雨刷嵌入件:通常以斷屑槽中的「W」來表示。

- 高進給刀片:名稱中可能有「HF」或類似字樣。

- 雙面插入:以插入特徵位置的特定字母表示。

製造商特定代碼

雖然 ISO 系統提供了標準化的基礎,但許多製造商仍會加入自己的代碼,以提供更特定的資訊:

- 山特维克可乐满:使用 'GC' 前綴來表示等級 (例如:GC4325)。

- Kennametal:使用 'KC' 前綴來表示其等級 (例如:KC5010)。

- Iscar:通常在等級稱謂中包含「IC」(例如 IC8150)。

瞭解插入式包裝

硬質合金刀片的包裝通常包含其他有價值的資訊:

- 建議的切削參數:速度、進給及切削深度範圍。

- 材料相容性:表示適合工件材料的符號或代碼。

- 批號:用於品質控制和追溯。

- 儲存建議:以保持插片品質。

在製造過程中的重要性

了解這些標記不僅對使用者而言至關重要,在硬質合金刀片的製造過程中也是如此。這些標記通常是在製造的最後階段加上去的:

- 雷射雕刻:使用精密雷射雕刻系統增加許多標記。

- 顏色編碼:有些製造商會使用顏色編碼的點或帶來表示等級或材料相容性。

- 品質控制:標記的準確性檢查是最終檢驗流程的一部分。

閱讀硬質合金刀片標記的技巧

- 有關製造商的特定編碼系統,請務必參閱製造商的目錄或網站。

- 請注意標記的順序,因為不同製造商的標記會略有不同。

- 使用放大鏡或放大鏡檢查小刀片,因為標記可能相當小。

- 如有疑問,請諮詢刀具製造商或切削刀具專家。

- 請記住,有些特殊或客製化的插入件可能不遵循標準 ISO 系統。

了解這些標記對於選擇適合特定加工作業的刀片是非常重要的。它可讓使用者快速辨識刀片的形狀、尺寸、公差及預期的應用。這方面的知識,再加上對硬質合金刀片製造過程的瞭解,可讓加工人員和工程師優化切削流程,以達到最高的效率和品質。

隨著製造技術的進步,我們可能會看到新的打標系統出現,以適應更複雜的刀片幾何形狀和先進的材料。對於任何在現代製造環境中使用切削工具的人而言,隨時掌握這些發展是至關重要的。

塗層硬質合金與非塗層硬質合金:有何差異?

在討論硬質合金刀片的製造方式時,必須先說明鍍膜與未鍍膜刀片的差異。

塗層硬質合金刀片提供:

- 增加耐磨性

- 更高的切割速度

- 刀具壽命更長

- 在某些應用中,表面光潔度更佳

非塗層硬質合金刀片提供:

- 更銳利的切削刃

- 在中斷切割時表現更佳

- 成本較低

- 適用於有色金屬材料

鍍膜與不鍍膜的選擇取決於特定的加工作業和工件材料。

硬質合金與 CBN:硬度與應用

在探索硬質合金刀片製造過程的同時,您也許會好奇其他超硬材料,例如立方氮化硼 (CBN)。CBN比硬質合金還硬嗎?

是的,CBN比硬質合金硬。然而,硬質合金刀片因其:

- 成本較低

- 更好的韌性

- 更廣泛的應用範圍

CBN 在加工淬硬鋼及鑄鐵方面表現優異,但價格較高且韌性較硬質合金差。

識別硬質合金刀片

如何判斷刀片是否為硬質合金?以下是一些特徵

- 暗灰色(用於無塗層嵌入件)

- 高密度 (感覺比看起來重)

- 磁性 (由於鈷含量)

- 極硬(可刮傷玻璃)

對於有塗層的刀片,塗層的顏色可以不同(例如 TiN 為金色,TiCN 為灰色)。

結論:硬質合金刀片製造的未來

了解硬質合金刀片的製造過程,對任何參與加工作業的人來說都是至關重要的。從原料的精心挑選到製程的精密控制,每一個步驟都會影響刀片的最終性能。

展望未來,材料科學與製造技術的發展將會帶來更精密的硬質合金刀片。奈米顆粒硬質合金、多層塗層及量身訂做的微小幾何形狀等創新技術,只是未來幾年可能重塑硬質合金刀片製造方式的幾個領域。

透過掌握硬質合金刀片製造過程的複雜性,工程師和加工人員可以做出更明智的決策,優化他們的切削作業,並突破金屬切削的極限。