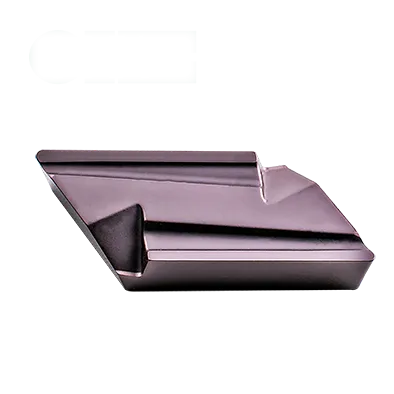

KNUX 插件

KNUX insert angle:0° Negative Rake Insert with single-sided Chipbreaker;

55° Parallelogram turning insert;

KNUX Inserts are designed with negative cutting edge and positive flank along the narrow edge;

Breaker Application: Semi-finshing and finishing machining;

Available in left or right hand;

Matching TurningTool Holder: CKNNR/L;

Material : Tungsten Carbide;

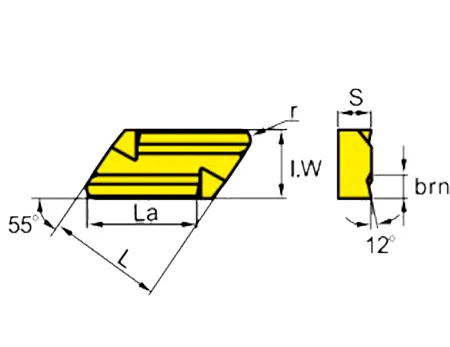

KNUX insert specification

KNUX Inserts are engineered for precision chamfering.

Their negative cutting edge and positive flank design ensure high hardness, wear resistance, and excellent strength, even in harsh conditions.

Expect minimal downtime thanks to fast, convenient blade replacement.

These carbide inserts deliver a smooth finish, simple operation, and consistent chamfering results – making them a cost-effective and reliable choice.

優勢

Maximize the productivity of your CNC equipment with KNUX Inserts.

Expect extended service life, reduced maintenance costs, and the precision that reflects our dedication to quality.

We offer competitive wholesale pricing on large orders, paired with the peace of mind of our top-notch after-sales service.

KNUX insert Meaning

Understanding the KNUX Insert Code

KNUX:

- K: Shape (rhombic with an 55-degree included angle, although the edge has a unique preparation).

- N: Clearance angle (0 degrees).

- U: Indicates a higher strength design

- X: Chipbreaker geometry and hole configuration (manufacturer-specific).

Numerical Digits

- 前兩個數字: Inscribed circle (IC) diameter in millimeters. Divide by 25.4 to get the approximate inch size.

- 下一個 2 位數: 厚度以毫米為單位。除以 25.4 轉換為英吋。

- 最後兩個數字: Corner radius in millimeters. Divide by 25.4 to convert to inches.

KNUX insert holder

CKNNR/L

DNMG Insert Dimensions (ISO and INCH)

| ISO 認證 | 刻字圓圈 (IC) | 厚度 | 轉角半徑 |

|---|---|---|---|

| KNUX 160405 | 16 公釐(0.63 吋) | 4.76 公釐(0.187 吋) | 0.5mm (0.02") |

| KNUX 160410 | 16 公釐(0.63 吋) | 4.76 公釐(0.187 吋) | 1.0mm (0.039") |

Example: KNUX 160405

- Rhombic shape with an 55-degree included angle and specialized edge preparation

- 0-degree clearance angle.

- Higher strength design

- 特定製造商的斷屑槽與孔位配置

- 16mm inscribed circle diameter (approx. 0.63″ in inches)

- 4.76mm thick (approx. 0.187″ in inches)

- 0.5mm corner radius (approx. 0.02″ in inches).

硬質合金刀片背後的科學:鎢鋼刀片的製造過程及強度原因

硬質合金刀片是目前用途最廣且最耐用的切削工具。但它們是如何製成的呢?是什麼讓它們如此堅固?在本影片中,我們將探討硬質合金刀片背後的科學,從碳化鎢的特性到製造過程。

我們的生產能力