Kaba freze

Kaba frezeler, iş parçasını nihai şekline yaklaştırmak için hızlı malzeme kaldırmaya odaklanarak öncelikle işlemenin ilk aşamalarında kullanılır. Uygulamaları çeşitli sektörleri ve üretim süreçlerini kapsar.

Kaba freze uygulaması

Yaygın Uygulamalar:

- Kalıp ve Kalıp Yapımı: İlk boşlukların ve formların oluşturulması.

- Otomotiv Endüstrisi: Motor bloklarının, şanzıman parçalarının ve diğer bileşenlerin işlenmesi.

- Havacılık ve uzay: Uçak ve uzay araçları için büyük metal parçaların işlenmesi.

- Genel İşleme: Son işlemlerden önce iş parçalarından fazla malzemenin çıkarılması.

Spesifik İşleme Operasyonları:

- Hogging: Büyük miktarda malzemenin hızlı bir şekilde çıkarılması.

- Yerleştirme: İş parçasında yarıklar veya oluklar oluşturma.

- Cepçilik: Ceplerin veya boşlukların frezelenmesi.

- Şekillendirme: Bir parçanın temel şeklinin kabaca çıkarılması.

Kaba freze özellikleri

Diş Geometrisi

- Agresif diş tasarımı: Finisaj frezelerine kıyasla daha büyük, daha geniş aralıklı dişlere sahiptir.

- Dalgalı veya tırtıklı diş profili: Talaşları etkili bir şekilde kırarak kesme kuvvetlerini azaltır ve talaş birikimini önler.

Flüt Tasarımı

- Daha derin flütler: Daha büyük talaş yüklerini barındırır ve talaş tahliyesini iyileştirir.

- Spiral flüt tasarımı: Talaş kaldırmayı geliştirir ve kesme kuvvetlerini azaltır.

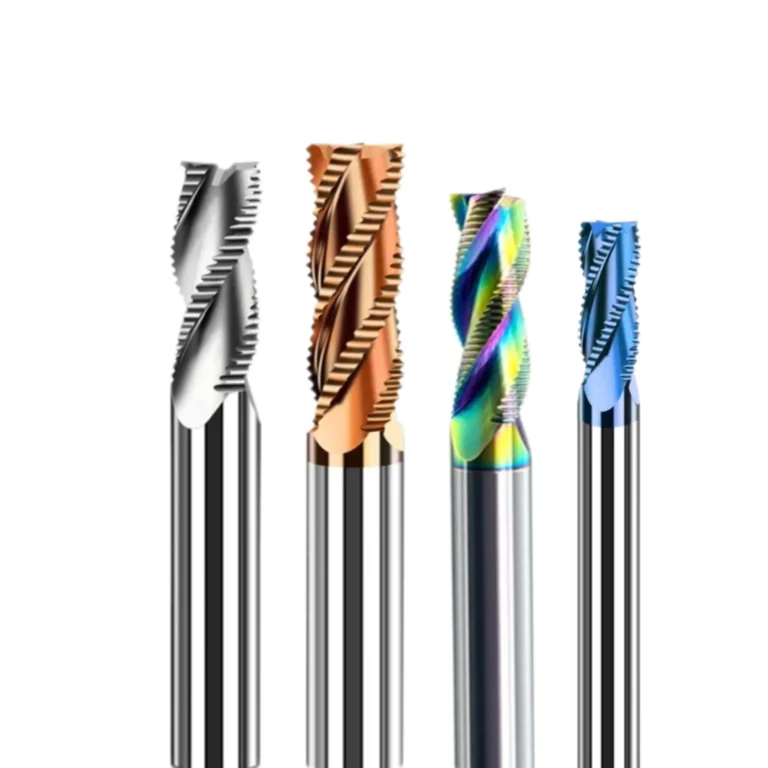

Malzeme ve Kaplama

- Daha sert malzemeler: Ağır kesme koşullarına dayanması için yüksek hız çeliğinden (HSS) veya karbürden yapılmıştır.

- Koruyucu kaplamalar: Genellikle aşınma direncini, ısı direncini ve takım ömrünü artırmak için uygulanır.

Genel Tasarım

- Daha büyük çap: Daha yüksek malzeme kaldırma oranları sağlar.

- Daha kısa flüt uzunluğu: Daha fazla sertlik sağlar ve titreşimi azaltır.

ULTRA MİKRO TANELİ KARBÜR & NANO TANELİ KARBÜR

Yüksek hassasiyetli işlemeyi mümkün kılan olağanüstü aşınma direnci sağlayan birinci sınıf karbür alt tabaka malzemeleri.

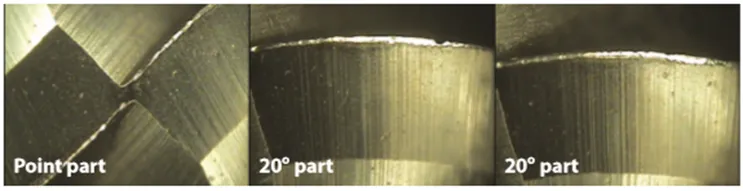

ÖZEL KÖŞE YARIĞI TASARIMI

- Benzersiz yiv tasarımı ve üstün köşe koruması, yüksek ilerlemeli uygulamalarda hem takım ömrünü hem de katastrofik arızalara karşı korumayı artırır.

- Mükemmel talaş akışı için parlatılmış oluklar.

BAŞVURU

Alüminyum alaşımı, bakır alaşımı, çinko alaşımı, magnezyum alaşımı vb. gibi daha yumuşak sertliğe sahip demir dışı metallerin işlenmesi için uygundur.

Rakip (Toplam Kesim Uzunluğu: 180m)

ONMY Parmak Frezeler (Toplam Kesme Uzunluğu: 300m)

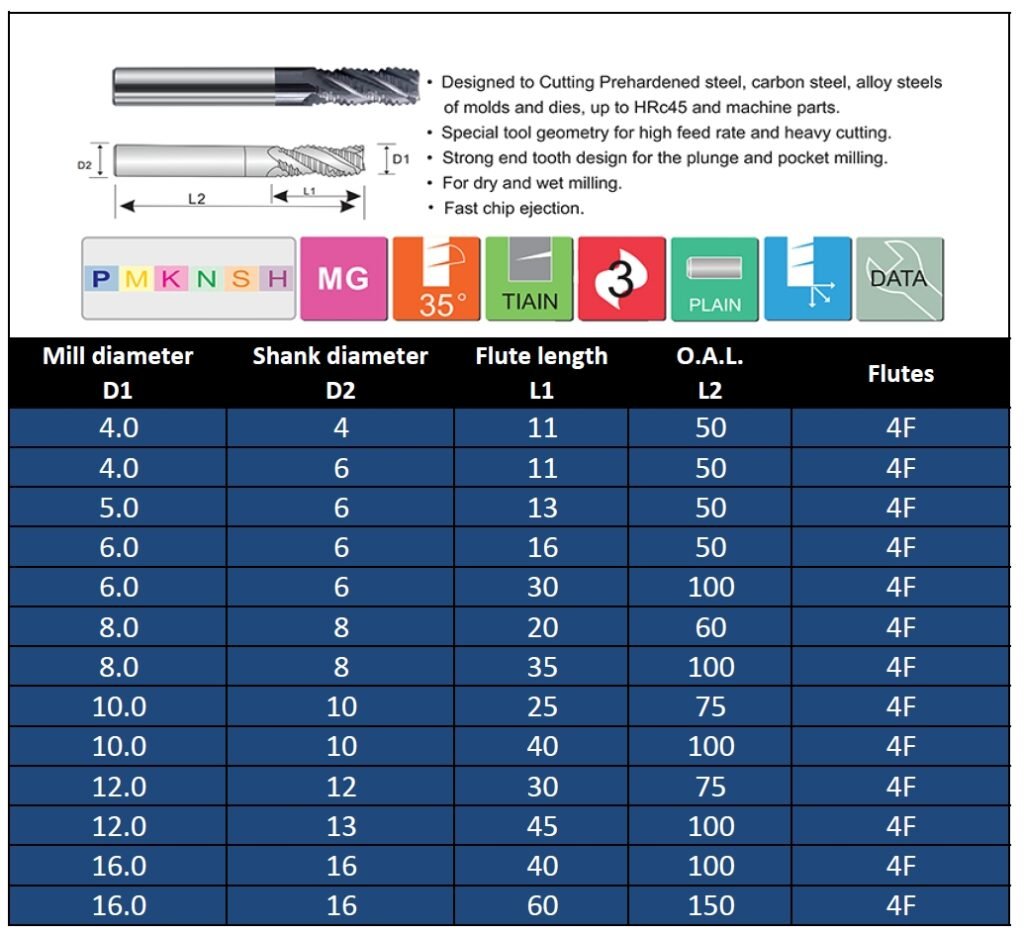

Kaba parmak freze kataloğu

ONMY TOOLINGS Farkı

Bizi ayıran şey tek ağızlı parmak freze ayrı mı? Bu, bizim benzersiz kombinasyonumuzdur:

Gelişmiş Karbür Formülasyonları

Güç ve aşınma direnci için optimize edilmiş tescilli mikro taneli karbür karışımları kullanıyoruz.

Yenilikçi Geometriler

Patentli oluk tasarımlarımız talaş tahliyesini en üst düzeye çıkarır ve kesme kuvvetlerini en aza indirir.

Son Teknoloji Kaplamalar

Isı direncini artıran ve sürtünmeyi azaltan nano katmanlı PVD kaplamalar uyguluyoruz.

Hassas Taşlama

Çok eksenli CNC taşlama makinelerimiz ±0,0005 inç kadar sıkı toleranslara ulaşır.

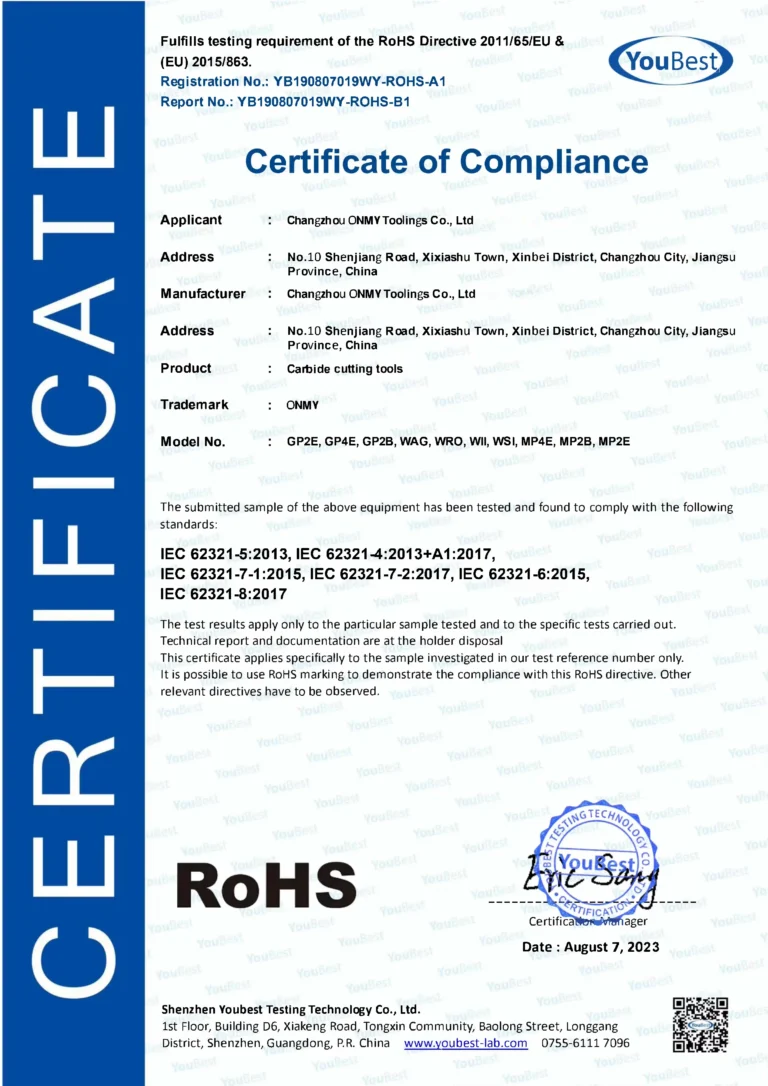

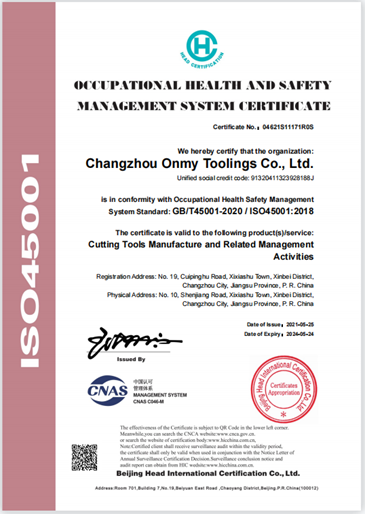

Fabrika Sertifikasyonu

Bu sertifikalar sadece süslü rozetler değildir - ürettiğimiz her alette tutarlı, en üst düzey kalitenin garantisidir. Kalite kontrol sürecimiz, her aletin titiz standartlarımızı karşıladığından emin olmak için kritik boyutların 100% incelemesini ve gelişmiş aşınma direnci testini içerir.

Mükemmellik Yolculuğumuz

Hikayemiz küçük bir atölyede büyük bir hayalle başladı: dünyanın en iyi bull nose parmak frezelerini yaratmak. Bugün, en son CNC taşlama teknolojisi ve gelişmiş kaplama sistemleriyle donatılmış son teknoloji ürünü 50.000 metrekarelik bir tesis işletiyoruz. Ancak gerçek gücümüz, ürettiğimiz her alete uzmanlıklarını katan tutkulu mühendisler ve yetenekli ustalardan oluşan ekibimizde yatıyor.

Özel ihtiyaçlarınıza göre uyarlanmış özel parmak frezelere sahip olmak varken neden hazır çözümlerle yetinesiniz ki? Şirket içi araştırma ve geliştirme ekibimiz sürekli olarak işleme teknolojisinde mümkün olanın sınırlarını zorluyor. Malzeme bilimi ve kesici takım tasarımının ön saflarında yer almak için önde gelen üniversiteler ve endüstri ortaklarıyla işbirliği yapıyoruz.

Sadece bizim sözümüze güvenmeyin. İşte memnun müşterilerimizin söyledikleri:

Mutlu Müşterim!

Özel Teklifinizi Şimdi Alın!

Not: Toplu indirimler sunduğumuzu söylemiş miydik? Ne kadar çok sipariş verirseniz, o kadar çok tasarruf edersiniz!

- Rakipsiz Fabrika Doğrudan Fiyatlandırması: Aracıyı devre dışı bırakın ve perakende fiyatlarına kıyasla 40%'ye kadar tasarruf edin. Verimli üretim sürecimiz, üstün kaliteyi rekabetçi fiyatlarla sunmamızı sağlar.

- Yıldırım Hızında Teslimat: Kolaylaştırılmış üretim sürecimizle, sektör lideri geri dönüş süreleri sunuyoruz. Özel parmak frezelerinizi 7 gün gibi kısa bir sürede teslim alın! Anında sevkiyat için geniş bir standart boyut envanterine sahibiz.

- Kişiselleştirilmiş Hizmet: Uzman mühendislerden oluşan ekibimiz, benzersiz işleme zorluklarınız için mükemmel çözümü bulmanıza yardımcı olmaya hazırdır. Özel ihtiyaçlarınızı analiz etmek ve ideal takım özelliklerini önermek için ücretsiz danışmanlık hizmeti sunuyoruz.

Sıkça Sorulan Sorular

Kaba işleme parmak frezesi öncelikle bir iş parçasından büyük miktarda malzemeyi hızla kaldırmak için kullanılır. Hedefin iş parçasını nihai ürünün kaba bir yaklaşımına göre şekillendirmek olduğu işlemenin ilk aşamalarında verimlilik için tasarlanmıştır.

Evet, kaba işleme frezeleri yüksek hızlı işleme (HSM) için kullanılabilir, ancak bazı hususlar göz önünde bulundurulmalıdır.

Geleneksel olarak daha düşük hızlarda ağır malzeme kaldırma için tasarlanmış olsa da, takım teknolojisindeki gelişmeler HSM için özel olarak optimize edilmiş kaba işleme parmak frezeleri üretmiştir. Bu takımlar şu özelliklere sahiptir:

- Optimize edilmiş diş geometrisi: Daha yüksek kesme hızlarının üstesinden gelmek ve daha küçük talaşlar üretmek için tasarlanmıştır.

- Geliştirilmiş talaş tahliyesi: Yüksek ilerleme hızlarında talaşları verimli bir şekilde kaldırır.

- Gelişmiş kaplamalar: HSM koşulları altında takım ömrünün ve performansının artırılması.

Ancak, özel HSM uygulamanız için doğru kaba işleme parmak frezesini seçmek çok önemlidir. Malzeme, makine kapasitesi ve istenen yüzey kalitesi gibi faktörler takım seçimini etkileyecektir.

Kaba freze, bir iş parçasından büyük miktarda malzemeyi hızla kaldırmak için tasarlanmış bir kesici takımdır. Özellikle, iş parçasını nihai ürünün kaba bir yaklaşımına göre şekillendirmenin amaçlandığı, işlemenin ilk aşamalarında verimlilik için tasarlanmıştır.

Bir kaba işleme parmak frezesinin temel özellikleri:

- Agresif diş geometrisi: Talaşları etkili bir şekilde kırmak ve kesme kuvvetlerini azaltmak için tasarlanmıştır.

- Daha büyük talaş yükleri: Finisaj frezelerine kıyasla daha ağır kesme yüklerini taşıyabilir.

- Daha pürüzlü yüzey kaplaması: Finisaj frezelerine kıyasla daha az rafine bir yüzey üretir.

Kaba Freze

- Amacımız: Bir iş parçasından büyük miktarda malzemeyi hızlı bir şekilde çıkarır.

- Tasarım: Agresif diş geometrisi, daha büyük talaş yükleri, daha hızlı ilerleme hızları.

- Sonuç: Pürüzlü yüzey kaplaması.

Son İşlem Frezesi

- Amacımız: İş parçası üzerinde pürüzsüz bir yüzey finişi elde eder.

- Tasarım: Daha küçük, daha keskin dişler, daha düşük talaş yükleri, daha yavaş ilerleme hızları.

- Sonuç: Pürüzsüz yüzey kaplaması.

Özünde:

- Kaba frezeler iş parçasını nihai boyutlarına yaklaştırmak için kullanılır.

- Son işlem frezeleri istenen yüzey kalitesini ve toleransları elde etmek için kullanılır.

Kaba Freze Kullanmanın Faydaları:

- Zaman tasarrufu: Hızlı malzeme kaldırma, işleme süresini azaltır.

- Alet ömrü: Kaba işleme için bir parmak freze kullanmaya kıyasla kesici takımda daha az aşınma.

- Uygun maliyetli: Optimize edilmiş malzeme kaldırma maliyetleri.

- Geliştirilmiş süreç güvenilirliği: Özel alet tasarımı sayesinde tutarlı sonuçlar.

Kaba freze satın almak için başlangıçta bir yatırım yapılması gerekse de, uzun vadeli faydalar genellikle maliyetten daha ağır basar. İş için doğru takımı kullanarak genel işleme verimliliğini artırabilir ve üretim maliyetlerini düşürebilirsiniz.