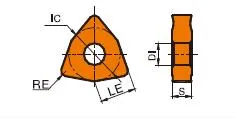

WNMGインサート

Wnmgインサート角度:0°ネガティブ・レーキ・インサート、両面チップブレーカー付き。

Wnmg超硬インサート内接円(Ic)9.525mm/12.7mm、厚さ3.97mm/4.76mm、コーナー(ノーズ)半径0.2mm/0.4mm/0.8mm/1.2mm;

加工シーン:荒加工/中仕上げ加工/仕上げ加工;

被削材:炭素鋼および合金鋼、ステンレス鋼および高温合金、鋼鉄および鋳鉄;

マッチング Wnmgインサートホルダー:swlnr/l, mwwnr/l, dwlnr/l, wwlnr/l, mwmnn, mwlnr/l ;

Wnmg超硬インサートサイズ:(Iso) Wnmg06t304; Wnmg06t308; Wnmg060404; Wnmg060408; Wnmg080404; Wnmg080408; Wnmg080412;

(Ansi) Wnmg331/ Wnmg332/ Wnmg431/ Wnmg432;

製品紹介

WNMGインサートは、異なるチップブレーカーとグレードを組み合わせることで、複数のオペレーションに対応することができます。

主な特徴

- 両面トライゴンデザイン**:工具寿命とコスト効率を最大化する、6つの切れ刃(片側3つずつ)を備えた80°トリゴン形状。

- 多彩なノーズ半径:0.2mm、0.4mm、0.8mm、1.2mmなどのオプションがあり、仕上げ用(小さい半径)または荒加工用(大きい半径)に使用でき、刃先の強度が向上します。

- アドバンストコーティング**:TiN、TiCN、AlTiN、またはCVD/PVD(TiAlN、TiCAN-Al2O3など)による耐摩耗性の向上、クレーターの減少、工具寿命の延長。

- 幅広い切削パラメータ:切り込み1.5~6.0mm、送り0.25~0.60mm/revをサポートし、荒加工から仕上げ加工まで対応。

- ニュートラルレーキまたはポジティブレーキ:切削力を低減し、チッピングを防止し、特にダブルポジティブ・チップブレーカでは切りくず排出性を高める。

WNMGインサート仕様

WNMGコードを理解する

WNMGの呼称に含まれる文字と数字には、重要な情報が含まれている:

- W: 80°の角度を含む三角錐形状

- N: ニュートラル(0°)すくい角

- M: 公差クラス(サイズの精度を示す)

- G: 特定のホールとチップブレーカーのデザインを示す(メーカーによって異なる)

数字だ:

- 通常、最初の2つの数字は、内接円(三角形の大きさ)を16分の1インチ(ISOコードの場合は直接ミリメートル)で表す。

- 3番目の数字は厚さを16分の1インチで表す。

- 最後の数字はノーズ半径を示すことが多い(小さいほどシャープ)。

超硬WNMGインサート寸法(ISOおよびANSI)

| インサートサイズ | ||||

|---|---|---|---|---|

| ISO指定 | ANSI指定 | インサイテッド・サークル(IC) | 厚さ | コーナー半径 |

| WNMG 060404 | WNMG331 | 6.35mm(0.25インチ) | 3.18mm(0.125インチ) | 0.4mm(0.016インチ) |

| WNMG 060408 | WNMG332 | 6.35mm(0.25インチ) | 3.18mm(0.125インチ) | 0.8mm(0.031インチ) |

| WNMG060412 | WNMG333 | 6.35mm(0.25インチ) | 3.18mm(0.125インチ) | 1.2mm(0.047'') |

| WNMG 080404 | WNMG431 | 8mm(0.315インチ) | 4.76mm(0.187インチ) | 0.4mm(0.016インチ) |

| WNMG 080408 | WNMG432 | 8mm(0.315インチ) | 4.76mm(0.187インチ) | 0.8mm(0.031インチ) |

| WNMG080412 | WNMG433 | 8mm(0.315インチ) | 4.76mm(0.187インチ) | 1.2mm(0.047'') |

例WNMG 080408 (ISO)

- トリゴン・シェイプ、ニュートラル・レーキ・インサート。

- 12.7mm(約1/2″)の内接円。

- 厚さ4.76mm(約3/16″)。

- 特定のチップブレーカー/穴の設計。

よくある質問

WNMGインサートを選択する:

- 工作物の材質: インサートのグレードを材料に合わせる。

- 回転操作のタイプ: 荒加工では強度を高めるためにノーズ半径を大きくする必要があり、仕上げ加工では表面仕上げを良くするために半径を小さくする必要がある。

- チップコントロール: WNMGでは、切削プロセスを最適化するために、完璧なチップブレーカ形状を選択することが非常に重要です。

重要な考慮事項

- WNMGチップは驚くほど多用途に使用できますが、その性能を最大限に発揮させる鍵は、特定の作業と材料に適したチップブレーカを選択することにあります。詳細については、メーカー資料をご参照ください。

超硬インサートの科学:その製造方法と強さの理由

超硬チップは、最も多用途で耐久性のある切削工具のひとつです。しかし、どのように作られるのでしょうか?また、なぜこれほど強いのでしょうか?このビデオでは、炭化タングステンの特性から製造工程まで、超硬チップの背後にある科学を探ります。

生産能力

現代の製造業において、高性能の超硬チップは欠かすことのできない工具であり、効率的で精密な金属加工の基礎を築いています。しかし、このような優れたチップは、単独で存在するのではなく、高度な機械の揺るぎないサポートによって支えられています。