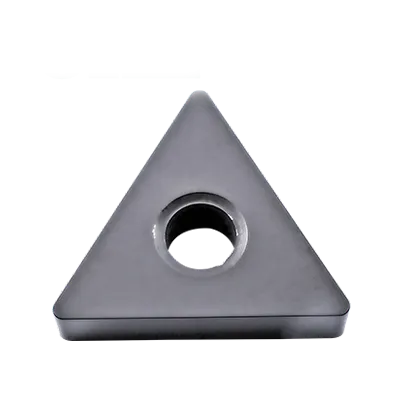

TNMAインサート

TNMA insert angle: 60°Triangle carbide insert; 0° Negative Rake Insert and double-sided no chipbreaker;

Breaker Application: cast iron machining;

TCMA insert inscribed circle (IC) of 9.525mm/12.7mm, thickness of 4.76mm, and corner (nose) radius of 0.4mm/0.8mm/1.2mm/1.6mm;

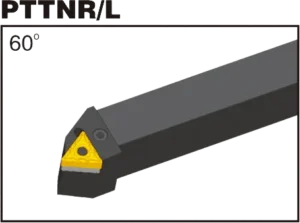

Matching TNMA insert Tool Holder: PTFNR/L,PTTNR/L,PTGNR/L,MTGNR/L,MTJNR/L,MTFNR/L;

TNMA Insert can deal with multiple operations by combining different grades;

材料:タングステンカーバイド;

製品の紹介

TNMA insert is a triangular 60° angle without chipbreaker specially designed for hard material machining, mainly used in cast iron machining, with good triangular stability, the negative type insert can effectively utilise 6 cutting edges, economical and efficient.

TNMA insert Specification

TNMA Designation

- T: Triangular shape.

- N: Negative rake angle (provides stronger cutting edge).

- M: Tolerance class (indicates precision of inscribed circle and thickness). Typically +/- 0.13mm.

- A: With cylindrical hole, without chipbreaker.

Common TNMA Dimensions

Similar to TCMT inserts, TNMA inserts use numbers to signify size:

TNMA 33X:

- Inscribed Circle (IC): 0.375″ (3/8″))

- Thickness: 0.125″ (1/8″))

- X represents nose radius in sixteenths of an inch (e.g., 1 = 1/32″))

TNMA 43X:

- Inscribed Circle (IC): 0.5″ (1/2″))

- Thickness: 0.188″ (3/16″))

- X represents nose radius

TNMA insert holder

MTJNR/L

TNMA carbide Insert Dimensions (ISO and ANSI)

| ISO TYPE | ANSI TYPE | LE | IC | S | DI | RE |

|---|---|---|---|---|---|---|

| TNMA160404 | TNMA 331 | 16.5 | 9.525 | 4.76 | 3.81 | 0.4 |

| TNMA160408 | TNMG332 | 16.5 | 9.525 | 4.76 | 3.81 | 0.8 |

| TNMA160412 | TNMG 333 | 16.5 | 9.525 | 4.76 | 3.81 | 1.2 |

| TNMA220408 | TNMG432 | 22 | 12.7 | 4.76 | 5.16 | 0.8 |

| TNMA220412 | TNMG433 | 22 | 12.7 | 4.76 | 5.16 | 1.2 |

| TNMA220416 | TNMG434 | 22 | 12.7 | 4.76 | 5.16 | 1.6 |

Example: TNMA 432

- T: Triangular

- N: Negative rake angle

- M: Tolerance class

- A: 60° included angle

- 4: Inscribed circle of 0.5″ (1/2″))

- 3: Thickness of 0.188″ (3/16″))

- 2: Nose radius of 0.0625″ (1/16″) – good for general purpose work

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

超硬インサートは、入手可能な切削工具の中で最も多用途で耐久性のあるものの一部です。しかし、それらはどのように作られるのでしょうか?そして何が彼らをそんなに強いのでしょうか?このビデオでは、炭化タングステンの特性から製造プロセスまで、超硬インサートの背後にある科学を探求します。

当社の生産能力