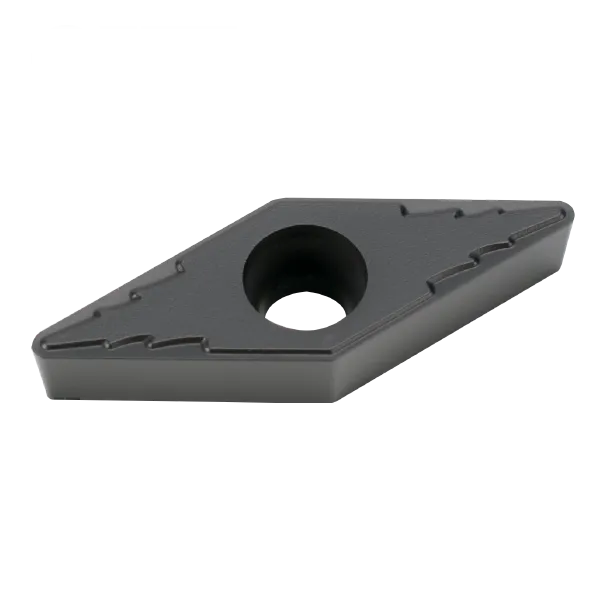

VBMT insert

VBMT insert angle :35 degree 5° Positive Rake Insert with single-sided Chipbreaker;

Screw-On Insert, finshing machining;

Matching VBMT insert holder: SVJBR/L, SVABR/L, SVVBN, SVQBR/L, SVUBR/L;

Range of VBMT insert types(ISO)VBMT1103/VBMT1604;(ANSI) VBMT221/ VBMT331/ VBMT332;

VBMT Insert can deal with multiple operations by combining different chip breakers and grades;

Material : Tungsten Carbide;

Product Introduction

The VBMT insert can equip with multiple chip breakers to deal with finishing, semi-finishing, and roughing works.

We also develop various applicable coatings to enhance productivity.

Key Features of VBGT Inserts

Forme :

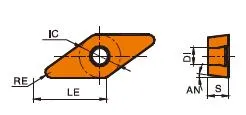

- V: Rhombic (diamond-shaped) with a 35° included angle. This sharp angle offers strength at the cutting tip and allows for versatility.

Angle de dégagement :

- B: 5° relief angle (clearance angle). This ensures the insert doesn’t rub on the workpiece.

Other Features

- Positive Rake Angle: The cutting face slopes slightly forward from the cutting edge, providing smoother cutting and lower cutting forces, suitable for softer materials or low-power machines.

- Chipbreakers: VBMt inserts often feature chipbreaker geometries to control chip formation and flow.

- Coatings: They can be coated with materials like TiN, AlTiN, etc., to improve wear resistance and tool life.

VBMT insert Specification

Understanding the VBMT Code

Here’s what the letters and numbers in the VBMt designation mean:

- V: 35° rhombic shape

- B: 5° relief angle (clearance angle)

- M : Tolerance class (indicates precision of the size)

- T: Can indicate hole type and chipbreaker design (varies by manufacturer)

- Numbers:

- Usually the first two numbers represent the inscribed circle (size of the diamond) in sixteenths of an inch (or directly in millimeters for ISO codes).

- The third number represents thickness in sixteenths of an inch.

- The last number often indicates the nose radius (smaller means sharper).

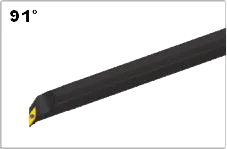

VBGT insert holder(Boring bar)

SVQBR/L

SVUBR/L

Carbide VBGT Insert Dimensions (ISO)

| Designation | Cercle inscrit (CI) | Épaisseur | Rayon de l'angle |

|---|---|---|---|

| VBMT 110302 | 11mm (0.43") | 3.18mm (0.125") | 0.2mm (0.008") |

| VBMT 110304 | 11mm (0.43") | 3.18mm (0.125") | 0,4 mm (0,016") |

| VBMT 160404 | 16mm (0.63") | 4,76 mm (0,187") | 0,4 mm (0,016") |

| VBMT 160408 | 16mm (0.63") | 4,76 mm (0,187") | 0,8 mm (0,031") |

Example: VBMT 160404 (ISO)

- 35° rhombic shape, positive rake insert.

- Inscribed circle of 12.7mm (approx. 1/2″).

- Thickness of 4.76mm (approx. 3/16″).

- Specific chipbreaker/hole design.

La science derrière les plaquettes en carbure : Comment elles sont fabriquées et pourquoi elles sont si résistantes

Les plaquettes en carbure comptent parmi les outils de coupe les plus polyvalents et les plus durables qui soient. Mais comment sont-elles fabriquées ? Et qu'est-ce qui les rend si résistantes ? Dans cette vidéo, nous allons explorer la science des plaquettes en carbure, des propriétés du carbure de tungstène au processus de fabrication.

Notre capacité de production