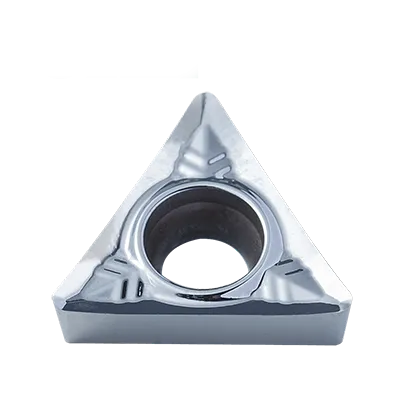

TCGX insert

TCGX insert angle: 7° Positive Rake Insert with Chipbreaker;

Screw-On Insert, finishing geometry with high positive rake face for chip control in long chipping materials;

Triangle carbide insert; And a single-sided chip breaker;

Breaker Application: Finshing machining;

Matching Turning Tool Holder: STFCR/L ;

Range of TCGX insert types:TCGX0902/TCGX1102/TCGX16T3;

TCGX Insert can deal with multiple operations by combining different chip breakers and grades;

Material : Tungsten Carbide;

TCGX insert Meaning

Understanding the TCGX Insert Code

- T: Shape: Trigon (triangle)

- C : Clearance Angle: 7 degrees (positive)

- G: Tolerance: Medium tolerance is standard, though other precision tolerances might be available.

- X : Chipbreaker style & Hole Configuration. This letter designates the specific chipbreaker geometry and whether the insert has a hole or not.

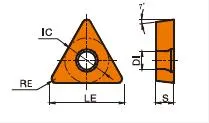

- Chiffres numériques :

- Deux premiers chiffres : Inscribed circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

- Prochain Deux Chiffres : Thickness in millimeters. Divide by 25.4 to convert to inches.

- Last Two Digits: Corner radius in millimeters. To convert to inches, divide by 25.4.

TCGX insert tool holder

TCGX carbide Insert Dimensions (ISO)

| Désignation ISO | Cercle inscrit (CI) | Épaisseur | Rayon de l'angle |

|---|---|---|---|

| TCGX 110202 | 11mm (0.433") | 2.38mm (0.094") | 0.2mm (0.008") |

| TCGX 110204 | 11mm (0.433") | 2.38mm (0.094") | 0,4 mm (0,016") |

| TCGX 16T304 | 16mm (0.63") | 3.18mm (0.125") | 0,4 mm (0,016") |

| TCGX 16T308 | 16mm (0.63") | 3.18mm (0.125") | 0,8 mm (0,031") |

Example: TCGX 16T308

- Trigon (triangle) shape

- 7-degree positive clearance angle

- Medium tolerance

- Manufacturer-specific chipbreaker and hole configuration

- 16mm inscribed circle diameter (approx. 0.63″ in inches)

- 3.18mm thick (approx. 0.125″ in inches)

- 0.8mm corner radius (approx. 0.031″ in inches).

La science derrière les plaquettes en carbure : Comment elles sont fabriquées et pourquoi elles sont si résistantes

Les plaquettes en carbure comptent parmi les outils de coupe les plus polyvalents et les plus durables qui soient. Mais comment sont-elles fabriquées ? Et qu'est-ce qui les rend si résistantes ? Dans cette vidéo, nous allons explorer la science des plaquettes en carbure, des propriétés du carbure de tungstène au processus de fabrication.

Notre capacité de production