Insert CCMT

CCMT insert angle:7° Positive rake insert with a single-sided chipbreaker;

80° rhombic turning insert;

CCMT insert specifications: CCMT060204/CCMT09T304/CCMT09T308/CCMT090308/CCMT1204;

Recommended for steel, stainless steel, cast iron, heat resistant alloy;

Breaker Application: Semi-finishing, finishing, general purpose and rough turning;

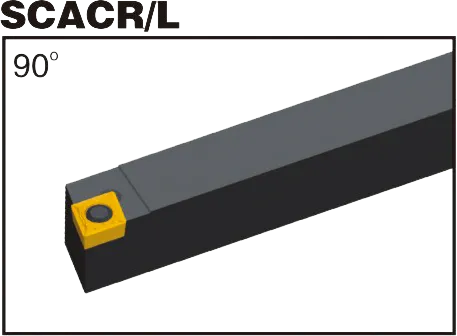

Matching CCMT insert turning tool holder: SCACR/L, SCLCR/L, SCFCR, SCLCR;

Material : Tungsten carbide

Grade: Both PVD and CVD;

CCMT insert tool holder

CCMT insert Introduction:

CCMT Inserts: The Essentials

- Forme: Rhombic (diamond) with an 80-degree included angle.

- Clearance Angle: 7 degrees (positive)

- Cutting Edges: Double-sided, offering two cutting edges per insert for cost-effectiveness.

- Chipbreaker Geometries: Diverse range of chipbreaker styles from various manufacturers are available. These are tailored to specific materials and machining operations (roughing, finishing, etc.)

- Key Uses: Ideal for turning, facing, and profiling operations on a range of materials.

Common Materials CCMT Inserts are Used For

- Steels: Various steel grades, including carbon and alloy steels.

- Stainless Steels: CCMT inserts can machine different stainless steel types.

- Cast Iron: Suitable for many cast iron applications.

- Some High-Temperature Alloys: Depending on the specific alloy and grade.

Advantages of CCMT Inserts

- Cost-Effective: Due to their double-sided design and wide availability.

- Versatile: The range of grades and chipbreakers make them suitable for many machining applications.

- Good Chip Control: Well-designed chipbreakers ensure effective chip flow and protect the workpiece, tool, and machine.

- Positive Rake Angle: This promotes efficient cutting and reduces cutting forces in many materials.

Important Considerations

- Match the Grade to Your Material: Choosing the right insert coating and substrate composition is crucial for optimal tool life and performance in the specific material you’re cutting.

- Select the Right Chipbreaker: The chipbreaker geometry significantly influences how chips are formed and broken. It should be chosen based on the material and type of machining operation.

- Machine Rigidity: Ensure your machine has enough rigidity and power to handle the cutting forces CCMT inserts can generate,

CCMT Insert Dimensions (ISO)

| TYPE | CCMT INSERT DIAMENTIONS(mm) | ||||

|---|---|---|---|---|---|

| LE | IC | S | DI | RE | |

| CCMT060204 | 6.4 | 6.35 | 2.38 | 2.8 | 0.4 |

| CCMT060208 | 6.4 | 6.35 | 2.38 | 2.8 | 0.8 |

| CCMT09T304 | 9.7 | 9.525 | 3.97 | 4.4 | 0.4 |

| CCMT09T308 | 9.7 | 9.525 | 3.97 | 4.4 | 0.8 |

| CCMT120404 | 12.9 | 12.7 | 4.76 | 5.56 | 0.4 |

| CCMT120408 | 12.9 | 12.7 | 4.76 | 5.56 | 0.8 |

| CCMT120412 | 12.9 | 12.7 | 4.76 | 5.56 | 1.2 |

Example: CCMT 09T308

- 09: Inscribed Circle (IC) of 9.52mm (approx. 0.375 inches)

- T3: Thickness of 3.18mm (approx. 0.125 inches)

- 08: Corner radius of 0.8mm (approx. 0.031 inches)

Key Dimensions

Inscribed Circle (IC): The diameter of the largest circle that fits within the insert. Common IC sizes include:

- 6,35 mm (0,25″)

- 9,52 mm (0,375″)

- 12,7 mm (0,5″)

Épaisseur: Impacts insert strength and the number of usable cutting edges. Common thicknesses include:

- 1.58mm (0.062″)

- 3,18 mm (0,125″)

- 4,76 mm (0,187″)

Corner Radius: Affects surface finish and strength at the cutting edge. Common sizes include:

- 0.2mm (0.008″)

- 00,4 mm (0,016″)

- 00,8 mm (0,031″)

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Les plaquettes en carbure comptent parmi les outils de coupe les plus polyvalents et les plus durables disponibles. Mais comment sont-ils fabriqués ? Et qu’est-ce qui les rend si forts ? Dans cette vidéo, nous explorerons la science derrière les plaquettes en carbure, des propriétés du carbure de tungstène au processus de fabrication.

Notre capacité de production