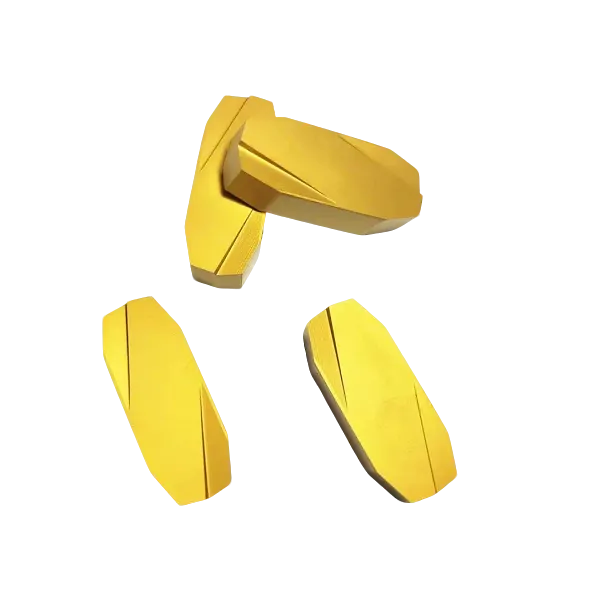

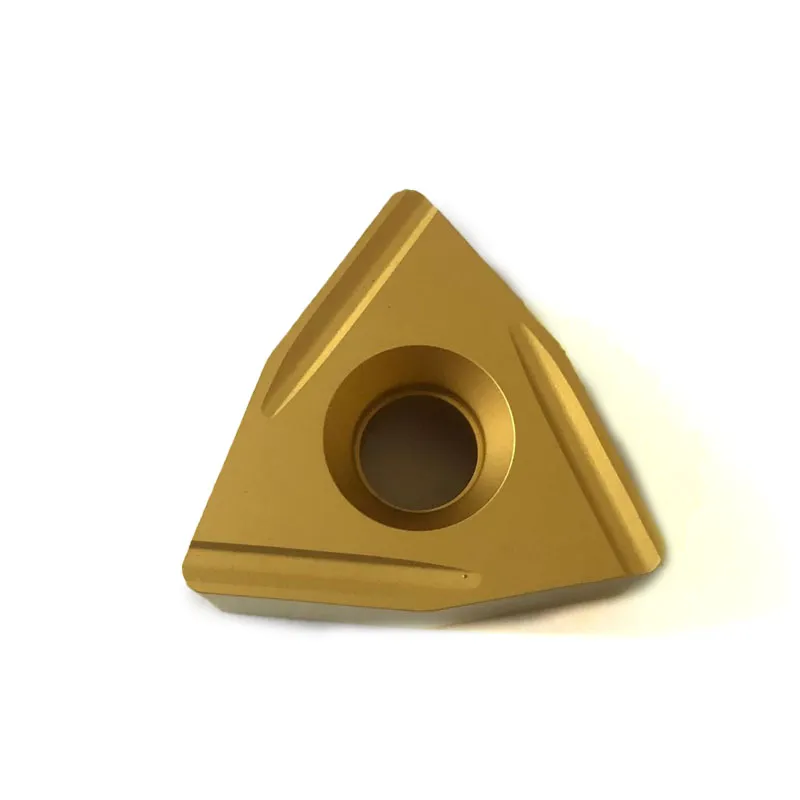

Inserts de pelage à barres

Bar Peeling Inserts are essential cutting tools used in bar peeling machines. Bar peeling is a precision machining process that removes surface defects, oxide layers, and decarburization from bars, aiming to improve surface finish, dimensional accuracy, and straightness. The quality of Bar Peeling Inserts directly affects peeling efficiency and machining quality. We offer a variety of Bar Peeling Inserts in different materials, coatings, and geometries to meet the bar peeling needs of various materials and machining requirements. These inserts are designed to provide superior cutting performance, extended tool life, and reduced production costs.

Applications

Bar Peeling Inserts can effectively peel various materials, including carbon steel, alloy steel, stainless steel, aluminum alloys, and copper alloys. Bar Peeling Inserts are widely used in the following industries and fields:

- Steel Industry: Used to remove scale and defects from the surface of steel billets, ingots, and bars, improving the quality of subsequent processing.

- Non-Ferrous Metals Industry: Used to peel non-ferrous metal bars such as aluminum, copper, and titanium, improving surface quality and precision.

- Automotive Manufacturing: Used to manufacture precision bars required for automotive parts, such as drive shafts and piston rods.

- Aerospace Industry: Used to produce bars required for high-precision, high-performance aerospace components.

- Machinery Manufacturing: Used for machining precision shaft parts required for various mechanical equipment.

Watch a Working Demonstration of Bar Peeling

Questions fréquemment posées

We offer Bar Peeling Inserts in various materials, including cemented carbide, ceramic, cermet, etc., to meet the peeling needs of different materials.

Choosing the right Inserts requires considering factors such as the material and diameter of the bar, the amount of peeling required, and the desired surface finish. You can consult our technical team for professional selection advice.

The service life of Inserts depends on various factors, including the bar material, cutting parameters, and cooling conditions. Our high-quality Bar Peeling Inserts are specially treated to maximize service life.

The bar peeling process is a precision machining technique used to remove surface imperfections, oxide layers (scale), decarburization, and other irregularities from metal bars. It employs specialized peeling machines and cutting tools (like the Bar Peeling Inserts we’ve been discussing) to remove a layer of material from the bar’s surface through rotary cutting. This achieves several key improvements:

- Improved Surface Finish: Creates a smoother bar surface, reducing friction and wear.

- Enhanced Dimensional Accuracy: Ensures a more precise bar diameter, meeting the requirements of high-precision parts.

- Improved Straightness: Corrects any bending in the bar, resulting in a straighter product.

- Removal of Surface Defects: Eliminates surface flaws like cracks, scratches, and scale, enhancing the overall material quality.

The bar peeling process is commonly used in industries such as steel and non-ferrous metals to produce high-quality bars for subsequent machining operations.

A peeled bar is a metal bar that has undergone the bar peeling process. Compared to unpeeled bars, peeled bars exhibit the following characteristics:

- Smooth Surface: Lower surface roughness and a higher degree of surface finish.

- Precise Dimensions: More accurate diameter with tighter tolerances.

- Good Straightness: Reduced bending and improved straightness.

- High Surface Quality: Free from significant surface defects like cracks, scratches, and scale.

Peeled bars are frequently used as raw materials for manufacturing high-precision components, such as shafts, drive shafts, and piston rods.

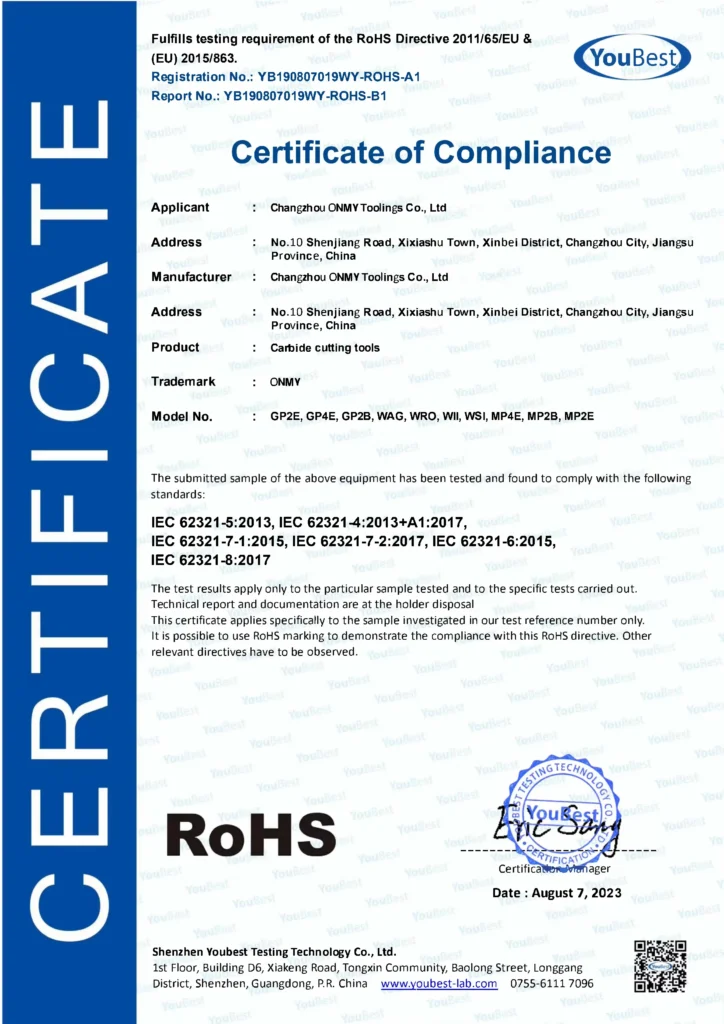

Notre engagement envers l'excellence

1 Certifications ISO: Nos processus de fabrication sont certifiés ISO 9001, garantissant une gestion de qualité cohérente dans toutes les opérations.

2 Conformité de l'industrie: Nous adhérons aux normes et réglementations spécifiques à l'industrie, y compris celles de la fabrication de dispositifs aérospatiaux et médicaux.

3 Responsabilité environnementale: Notre engagement envers la durabilité se reflète dans nos processus de fabrication respectueux de l'environnement et nos pratiques responsables de gestion des déchets.

4 Approche centrée sur le client: Nous croyons à la création de partenariats à long terme avec nos clients. Notre équipe d'assistance technique est toujours prête à vous aider à sélectionner les bons outils et à optimiser vos processus d'usinage.

VOIR POUR CROIRE !

Je n'en croirai pas vos yeux ! Nos superbes photos présentent tous les angles et détails de notre usine fiable. En tant que client importateur, vous ne pouvez pas vous permettre de manquer ces visuels à couper le souffle. Voir pour croire!

What Our Customers Say About Bar Peeling Inserts