Inserto DCGT

DCGT insert angle:7° Positive rake insert with a single-sided Chipbreaker;

55° Rhombic turning insert;

Primary workpiece material: Aluminium;

Breaker application: Semi-finshing and finishing machining;

Matching turning tool holder: SDQCR/L, SDUCR/L;

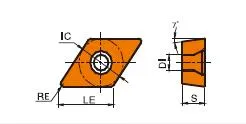

DCGT insert dimensions:DCGT0702/DCGT11T3;

Material : Tungsten carbide;

DCGT insert specification

Finishing geometry with high positive rake face for chip control in long chipping materials.

DCGT insert tool holder

DCGT insert Introduction

- D: Shape. Rhombic (diamond) with a 55-degree included angle.

- C: Clearance Angle. 7 degrees (positive).

- GRAMO: Tolerance. Medium (‘G’) is standard, though other precision tolerances exist.

- T: Chipbreaker style & Hole Configuration. This letter designates the specific chipbreaker geometry and whether the insert has a hole or not. Chipbreaker variations are numerous and manufacturer-specific.

- Numerical Digits:

- First Two Digits: Inscribed circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

- Next Two Digits: Thickness in millimeters. Divide by 25.4 to convert to inches.

- Last Two Digits: Nose radius in millimeters. To convert to inches, divide by 25.4.

DCGT Insert Dimensions (ISO)

| Designación ISO | Círculo inscrito (IC) | Espesor | Radio de la esquina |

|---|---|---|---|

| DCGT 070202 | 7.94mm (0.313") | 2.38mm (0.094") | 0.2mm (0.008") |

| DCGT 070204 | 7.94mm (0.313") | 2.38mm (0.094") | 0.4mm (0.016") |

| DCGT 11T302 | 11mm (0.433") | 3.18mm (0.125") | 0.2mm (0.008") |

| DCGT 11T304 | 11mm (0.433") | 3.18mm (0.125") | 0.4mm (0.016") |

| DCGT 11T308 | 11mm (0.433") | 3.18mm (0.125") | 0.8mm (0.031") |

Example: DCGT 11T308

- Rhombic (diamond) shape with a 55-degree included angle

- 7-degree positive clearance angle

- Medium tolerance

- Manufacturer-specific chipbreaker and hole configuration

- 11mm inscribed circle diameter (approx. 0.43″ in inches)

- 3.18mm thick (approx. 0.125″ in inches)

- 0.8mm nose radius (approx. 0.031″ in inches)

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Los insertos de carburo son algunas de las herramientas de corte más versátiles y duraderas disponibles. Pero, ¿cómo se hacen? ¿Y qué los hace tan fuertes? En este video, exploraremos la ciencia detrás de las inserciones de carburo, desde las propiedades del carburo de tungsteno hasta el proceso de fabricación.

Nuestra capacidad de producción