Ejercicios en U

Una broca en U, también conocida como broca de plaquita intercambiable o broca modular, es una herramienta de corte de precisión diseñada para realizar agujeros de forma eficaz en el mecanizado CNC. Se caracteriza por su diseño de canal en forma de U y sus plaquitas de metal duro sustituibles, y destaca en el taladrado de agujeros superficiales y profundos en diversos materiales, como acero, acero inoxidable, aluminio y materiales compuestos. A diferencia de las brocas helicoidales tradicionales, las brocas en U utilizan un sistema modular con un cuerpo de herramienta duradero y plaquitas intercambiables, lo que las hace muy adaptables a aplicaciones de alta velocidad y alto avance.

Ventajas de Ejercicios en U: Las brocas U ofrecen importantes ventajas que mejoran la eficiencia del mecanizado. Su diseño de ranura en forma de U garantiza una evacuación superior de las virutas, lo que reduce las obstrucciones y permite velocidades de avance más rápidas, lo que puede reducir los tiempos de ciclo hasta en un 70 %. El sistema de plaquitas reemplazables prolonga la vida útil de la herramienta y reduce el tiempo de inactividad, ya que las plaquitas desgastadas se pueden cambiar en cuestión de minutos sin necesidad de sustituir toda la broca. Además, las brocas U proporcionan una excelente rigidez, lo que permite altas velocidades de avance y diámetros de procesamiento más grandes (hasta 60 mm), al tiempo que ofrecen una precisión milimétrica en los agujeros y acabados superficiales superiores, lo que a menudo elimina la necesidad de operaciones de mandrinado secundarias.

Las brocas en U de ONMY destacan por su excelente calidad y rendimiento, fabricadas con materiales de alta calidad para garantizar su durabilidad y resistencia al calor. Centrada en la innovación, ONMY ofrece una amplia gama de calidades y geometrías de plaquita adaptadas a diversos materiales y aplicaciones, con el apoyo de un asesoramiento técnico experto. Con el respaldo de ventas directas de fábrica, una rigurosa gestión 6S y un servicio posventa 24/7, ONMY garantiza soluciones rentables y un soporte fiable, lo que convierte a sus brocas en U en la opción ideal para lograr resultados de mecanizado de primer nivel.

- Rango de mecanizado de agujeros:2D-6D

- Serie 2D/3D/4D SP inserto mecanizado agujero rango:14mm-70mm

- Serie 2D/3D/4D WC inserto mecanizado agujero rango:14mm-90mm

- 5D Serie SP/WC inserto mecanizado agujero rango:14mm-70mm

- Serie 5D WC inserto mecanizado agujero rango:14mm-70mm

- Serie 6D WC inserto mecanizado agujero rango:20mm-70mm

- Admite tamaños enteros y no enteros

- Soporta materias primas 40Cr y H13

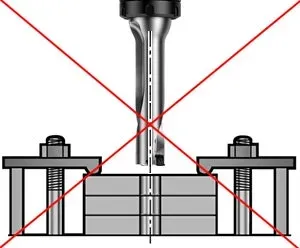

advertencia

- Las brocas en U se queman fácilmente cuando se utilizan descentradas en un torno.

- Cuando se utiliza un tamaño pequeño Taladro en U, Se requiere alta velocidad y alto avance. Cuanto menor sea el avance y la velocidad, mayor será la resistencia al corte y más fácil será quemar la herramienta.

Brocas en U

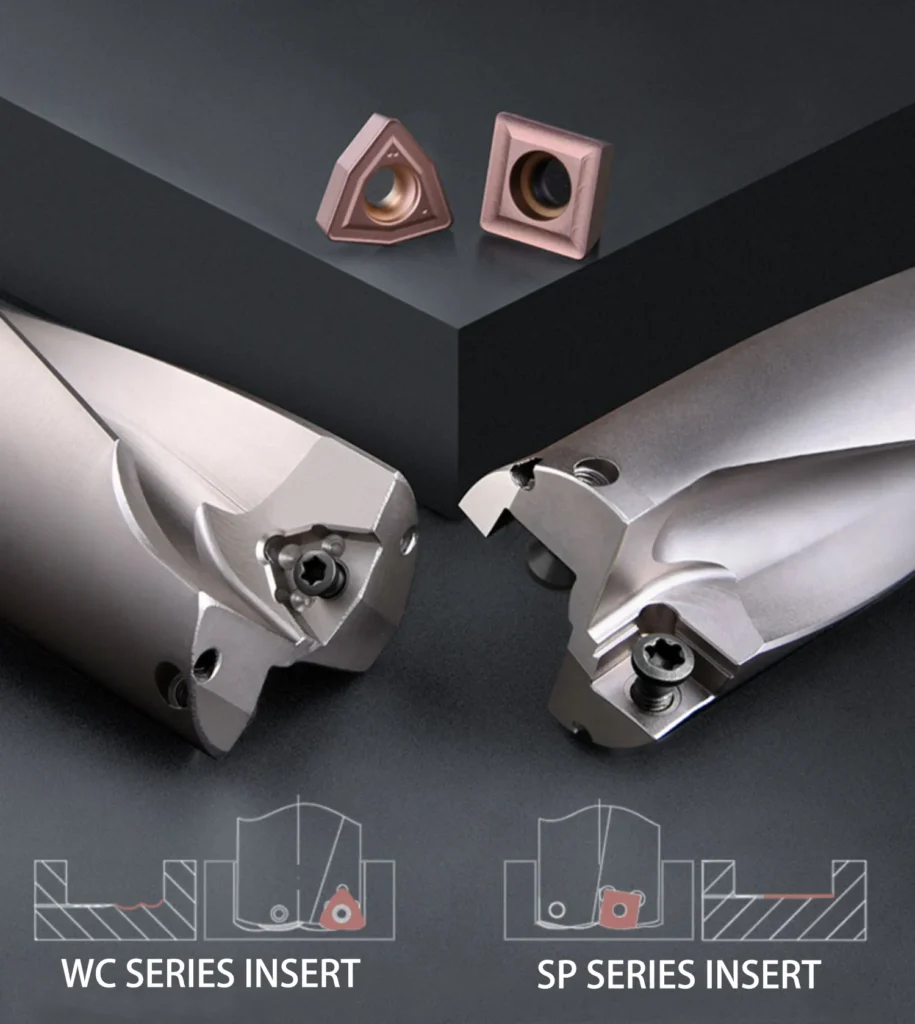

Inserto SOMT

Support SOMT050204,SOMT060204,SOMT070306,SOMT08T306,SOMT09T308,SOMT11T308,SOMT130408,SOMT150510 sizes.

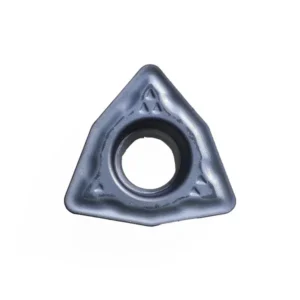

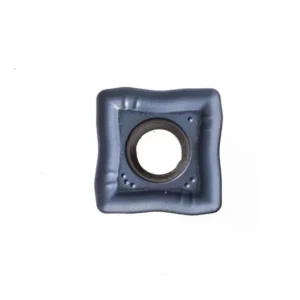

Cuerpos de broca en U para plaquitas SPMG

Cuerpos de broca en U para plaquitas WCMT

Diferentes insertos de la serie WC&SP

- Mayor eficacia de procesamiento de la serie WC

- El procesamiento de la serie SP tiene un mayor grado de acabado

- Los insertos de la serie WC son más baratos

- Serie SP Mecanizado Superficie Inferior Plana

- Las plaquitas de la serie WC tienen 3 filos de corte.

- Las plaquitas de la serie SP tienen 4 filos de corte.

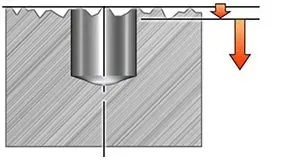

Optimizado para chipformer más profundo

Mayor velocidad de eliminación de virutas, lo que afecta directamente a la eficiencia del mecanizado, ranura de eliminación de virutas más profunda. Mejora en el avance y la velocidad elevados, sin acumulación de virutas, inserto no pegajoso, bisel del filo más pequeño, optimización y mejora de la rigidez de la u taladro cuerpo.

Diseño de precisión para evitar el bamboleo de la plaquita

Los filos de corte central y periférico precisos pueden inhibir eficazmente la oscilación cuando se mecaniza con fuerza uniforme; reducen el riesgo de golpeo de la herramienta en entornos de materiales difíciles de mecanizar, y proporcionan mejor precisión/estabilidad que las brocas rápidas generales.

Nota: Un inserto con borde periférico no se puede utilizar como borde central; del mismo modo, un inserto con borde central no se puede utilizar como borde periférico; tenga cuidado al sustituir el borde.

Doble tornillo con orificio para aceite de alta alimentación

Los orificios de aceite helicoidales dobles protegen la vida útil de la plaquita y ayudan a refrigerar la broca. Cuanto menor es el tamaño de la broca rápida, más importante es seguir un régimen alto de RPM/avance alto para minimizar la resistencia al corte.

Póngase en contacto con nosotros para más información

Fórmula común de mecanizado de brocas en U

(Datos de referencia)

Velocidad de corte (Vc)

Vc= Dc*π*n/1000

- Dc(mm) :diámetro de la broca

- Vc(m/min): velocidad de corte

- n(rev/min):velocidad de rotación

Ejemplo

La velocidad del husillo es de 1600rev/min, el diámetro de la broca es de 20mm, la velocidad de corte es: Vc = Dc*π*n/1000 = 20*3.14*1600/1000 = 100 (m/min)

Velocidad de avance (Vf)

Vf=Fr*n

- Vf(m/min):velocidad de avance

- Fr(mm/rev):cantidad de avance por revolución

- n(rev/min):velocidad del cabezal

Ejemplo

La velocidad del husillo es de 1350 min-1 y el diámetro de la broca Ø12, hallar la velocidad de corte.

(Respuesta)

Sustituya la fórmula

vf=f×n=0.2×1350=270mm/min

El avance del husillo por minuto es de 270 mm/min.

Tiempo de procesamiento del agujero (Tc)

Tc= ld*i/n*f

- Tc(min):tiempo de mecanizado

- i:número de agujeros

- Fr(mm/rev):avance por revolución

- n(rev/min):velocidad del cabezal

- ld:profundidad de perforación

Ejemplo

Se taladra un agujero de Ø15 y 30 mm de profundidad en acero SCM440. La velocidad de corte es de 50 m/min y el avance por revolución es de 0,15 mm/rev. Hallar el tiempo de taladrado.

(Respuesta)

Velocidad del husillo n=(50×1000)÷(15×3,14)=1061,57min-1

Tc = (30 × 1) ÷ (1061,57 × 0,15) = 0,188

= 0,188 × 60 = 11,3 segundos para perforar.

Índice de arranque de metal (Q)

Q=Vc*Dc*Fn/4

- Vc(m/min):velocidad de corte

- Dc(mm):Diámetro de perforación

- Fn(mm/r):avance

u parámetros de perforación

(Datos de referencia)

| Materiales | Dureza | Velocidad de corte | Taladro U diámetro | |||

| 17.5-22 | 22.2-30 | 30.5-40 | 40.5-50 | |||

| Aceros | 80-180 | 200-280 | 0.05-0.1 | 0.07-0.12 | 0.1-0.2 | 0.15-0.25 |

| Aceros | 150-225 | 150-220 | 0.05-0.12 | 0.08-0.15 | 0.12-0.25 | 0.18-0.28 |

| Aceros de baja aleación | 150-260 | 160-220 | 0.06-0.12 | 0.08-0.18 | 0.15-0.3 | 0.2-0.3. |

| Aceros de alta aleación | 150-240 | 120-180 | 0.05-0.1 | 0.06-0.15 | 0.12-0.2 | 0.18-0.25 |

| Aceros inoxidables | 150-250 | 100-200 | 0.05-0.1 | 0.07-0.12 | 0.12-0.2 | 0.15-0.22 |

| Aceros para herramientas | 170-270 | 120-200 | 0.05-0.12 | 0.07-0.15 | 0.12-0.22 | 0.15-0.25 |

| Hierro fundido | 160-220 | 120-180 | 0.1-0.17 | 0.15-0.2 | 0.18-0.25 | 0.2-0.3 |

| Fundición aleada | 150-260 | 110-180 | 0.08-0.14 | 0.12-0.18 | 0.15-0.22 | 0.18-0.25 |

| Aleación de aluminio | 40-140 | 250-350 | 0.075-0.15 | 0.1-0.18 | 0.15-0.25 | 0.18-0.3 |

| Aluminio fundido | 50-150 | 220-280 | 0.1-0.2 | 0.15-0.22 | 0.18-0.3 | 0.22-0.35 |

u requisitos de potencia de procesamiento del taladro

Para utilizar realmente el efecto de mecanizado de la broca en U, además del portaherramientas y la plaquita, también necesita la máquina adecuada para poder utilizar la capacidad de mecanizado real de la broca en U.

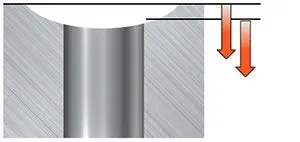

Perforación de superficie irregular

Irregular

- Utilice la broca más corta posible para minimizar las tendencias a la vibración y disminuir los efectos de la desviación

- Valores iniciales recomendados para la velocidad de corte y el avance mínimo recomendado

- No recomendado para 6-7×DC cuando el radio del cóncavo es igual o menor que el radio de la broca.

Convexo

- Utilice la broca más corta posible para minimizar las tendencias a la vibración y disminuir los efectos de la desviación

- Valores iniciales recomendados para la velocidad de corte y el avance mínimo recomendado

- No recomendado para 6-7×DC cuando el radio del cóncavo es igual o menor que el radio de la broca.

Cóncavo

- Utilice la broca más corta posible para minimizar las tendencias a la vibración y disminuir los efectos de la desviación

- Valores iniciales recomendados para la velocidad de corte y el avance mínimo recomendado

- No recomendado para 6-7×DC cuando el radio del cóncavo es igual o menor que el radio de la broca.

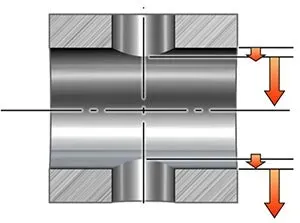

Taladrado transversal

- Para orificios de distinto diámetro: taladre primero el orificio mayor para reducir la formación de rebabas.

- Empezar con el avance más bajo recomendado durante el cruce de agujeros

- No se recomienda en materiales de viruta larga debido a la evacuación de virutas al cruzar los orificios.

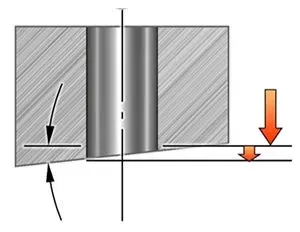

Superficies en ángulo o inclinadas, entrada

- Utilice la broca más corta posible para minimizar las tendencias a la vibración y disminuir los efectos de la desviación

- Comenzar con la velocidad de corte más baja recomendada y 1/3 del avance más bajo recomendado (o inferior) hasta que esté completamente engranado y luego volver al avance normal.

- 4-5×DC la entrada inclinada puede inclinarse hasta 15º

- 6-7×DC la entrada inclinada puede inclinarse hasta 10º

Superficies angulosas o inclinadas, salida

- Utilice la broca más corta posible para minimizar las tendencias a la vibración y disminuir los efectos de la desviación

- Valores iniciales recomendados para la velocidad de corte y el avance mínimo recomendado (o inferior)

- 4-5×DC la salida inclinada puede inclinarse hasta 15º

- 6-7×DC la salida inclinada puede inclinarse hasta 5º

Taladrado de superficies curvas asimétricas

- Utilice la broca más corta posible para minimizar la curvatura de la broca hacia el exterior desde el centro, similar a una superficie inclinada

- Reducir el avance a 1/3 de la penetración inicial para superficies cóncavas

- El radio de la superficie curva debe ser mayor que el radio de la broca

- No recomendado para taladros 6-7×DC

Orificios pretaladrados

- Para mantener la fuerza de corte equilibrada entre la plaquita central y la periférica a un nivel aceptable, el agujero pretaladrado no debe ser mayor que DC/4

perforación por apilamiento

- Reducir al mínimo la separación entre las placas apiladas es crucial para el éxito de la perforación apilada. Esto puede hacerse sujetando o soldando las placas entre sí. Una buena práctica habitual es insertar papel industrial (de un grosor aproximado de 0,5-1 mm) entre las placas para nivelar cualquier irregularidad y amortiguar las vibraciones. Como la fuerza axial será de varios miles de newtons durante el proceso de perforación, los soportes de sujeción son una consideración importante.

Póngase en contacto con ONMY para crear su empresa

Eche un vistazo a cómo perciben nuestros productos y servicios algunos de nuestros clientes:

Nuestras ventajas

- Nuevas materias primas, primer paso para controlar la calidad del producto.

- Ventas directas de fábrica, se negó a intermediarios ganan diferencia de precio.

- 6S gestión, proceso estandarizado, la fuente para eliminar los productos problemáticos fuera de la fábrica.

- Expertos profesionales en ventas resuelven la mayoría de sus problemas de mecanizado.

- Garantía post-venta cualquier problema del producto 7 * 24 horas de servicio.