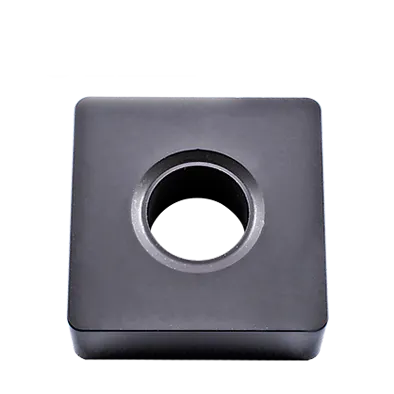

SNMA insert

SNMA carbide insert angle: 90° Square carbide insert; 0° Negative Rake Insert and No Chipbreaker;

90° 方形硬質合金刀片,適用於多種材料;

Breaker Application: Roughing machining;

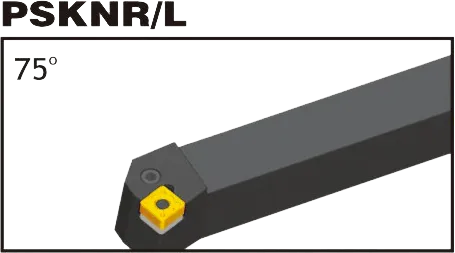

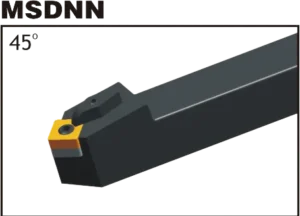

Matching SNMA Tool Holder: MSKNR/L,MSDNN,MSBNR/L,PSBNR/L,PSDNN,PSKNR/L;

SNMA Insert can deal with multiple operations by combining different chip breakers and grades;

材質 : 碳化鎢;

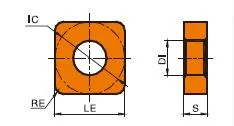

規格

SNMA carbide inserts have 4 cutting edges per side. If the insert is negative then it is possible to use a total of 8 corners.

In this case, it makes this style of insert very economical.

It has a cutting edge angle of 90° so it has high cutting edge strength.

Normally, the insert dimension depends on the needs of customers and the space for the cutting tools in the application.

In addition, the Indexable Carbide Insert has gone through various processes such as quenching to improve its performance.

The surface has been treated with a special coating, thus it gains the properties of corrosion resistance and rustproof.

What’s more, it has the properties of good positioning accuracy, high hardness, long service life, wear resistance, corrosion resistance as well as cost effective.

The Indexable Carbide Insert is widely applied in metal turning, milling, cutting and grooving, thread turning, etc.

SNMA insert Meaning

Understanding the SNMA Insert Code

- S: 形狀:方形

- N: Clearance Angle: Negative

- M: 公差:中等公差是標準公差,但也可能有其他精密公差。

- A: 斷屑槽型式與孔配置。此字母表示特定的斷屑槽幾何形狀,以及刀片是否有孔。斷屑槽的種類繁多,並依製造商而異。

- 數字位數:

- 前兩個數字: 刻圓 (IC) 直徑,單位為毫米。若要取得近似的英吋等值,請將此數除以 25.4。

- 下一個 2 位數: 厚度以毫米為單位。除以 25.4 轉換為英吋。

- 最後兩個數字: 以毫米為單位的轉角半徑。若要轉換為英吋,除以 25.4。

SNMA insert holder

SNMA carbide Insert Dimensions (ISO)

| ISO 認證 | 刻字圓圈 (IC) | 厚度 | 轉角半徑 |

|---|---|---|---|

| SNMA 090308 | 9.52 公釐(0.375 吋) | 3.18 公釐(0.125 吋) | 0.8 公釐(0.031 吋) |

| SNMA 120404 | 12.7 公釐(0.5 吋) | 4.76 公釐(0.187 吋) | 0.4 公釐(0.016 吋) |

| SNMA 120408 | 12.7 公釐(0.5 吋) | 4.76 公釐(0.187 吋) | 0.8 公釐(0.031 吋) |

| SNMA 120412 | 12.7 公釐(0.5 吋) | 4.76 公釐(0.187 吋) | 1.2 公釐(0.047 吋) |

| SNMA 150412 | 15.875mm (0.625") | 4.76 公釐(0.187 吋) | 1.2 公釐(0.047 吋) |

| SNMA 190612 | 19.05 公釐(0.75 吋) | 6.35 公釐(0.25 吋) | 1.2 公釐(0.047 吋) |

Example: SNMA 120408

- 方形

- 負間隙角

- 中等容忍度

- 特定製造商的斷屑槽與孔位配置

- 12.7mm inscribed circle diameter (approx. 0.5″ in inches)

- 4.76mm thick (approx. 0.187″ in inches)

- 0.8mm 轉角半徑(以英吋計約 0.031″)。

硬質合金刀片背後的科學:鎢鋼刀片的製造過程及強度原因

硬質合金刀片是目前用途最廣且最耐用的切削工具。但它們是如何製成的呢?是什麼讓它們如此堅固?在本影片中,我們將探討硬質合金刀片背後的科學,從碳化鎢的特性到製造過程。

我們的生產能力