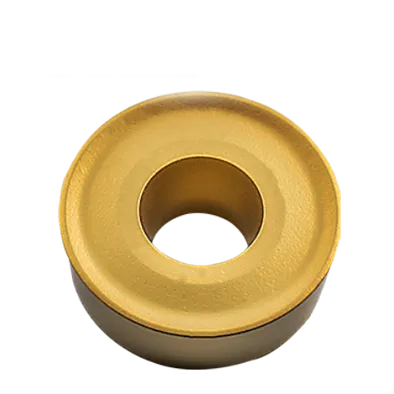

RCMX 插件

RCMX insert angle: 7° Positive Rake Screw-On Insert with single-sided Chipbreaker;

Recommended for wide range of materials

Round carbide insert;

Breaker Application: Semi-roughing & Roughing machining

Matching TurningTool Holder: SRGCRL,SRDCN

RCMX Insert can deal with multiple operations by combining different chip breakers and grades.

材質 : 碳化鎢

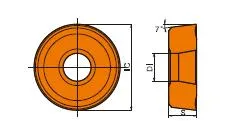

RCMX insert specification

RCMX round insert suitable for roughing and semi-roughing, the special chipformer design ensures the rigidity of the insert in the face of the complexity of roughing, but also ensures that it is capable of continuous machining.

RCMX insert Meaning

Understanding the RCMX Insert Code

- R: Shape: Round. RCMX inserts are round but have cutting edges spaced around the circumference for indexing.

- C: Clearance Angle: Positive, often small (around 7 degrees) for general-purpose use, though variations for specific materials can exist.

- M: Tolerance: Medium tolerance (‘M’) is most typical, but precision tolerances might be available.

- X: Chipbreaker style & Hole Configuration. This letter denotes the specific chipbreaker and whether the insert has a hole. Chipbreaker variations are manufacturer-specific, so always check their resources.

- 數字位數:

- 前兩個數字: Inscribed Circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

- 下一個 2 位數: May refer to thickness or other dimensions depending on the manufacturer. It’s crucial to consult the specific manufacturer’s catalog.

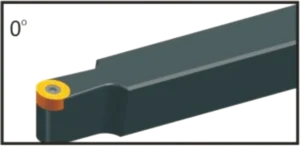

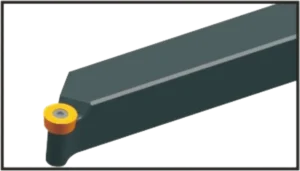

RCMX insert holder

SRDCN

SRGCRL

RCMX Insert Dimensions (ISO)

| RCMX Designation | LE | IC | S | D1 |

|---|---|---|---|---|

| RCMX 0803MO | 8 | 8 | 3.18 | 3.4 |

| RCMX 1003MO | 10 | 10 | 3.18 | 3.6 |

| RCMX 1204MO | 12 | 12 | 4.76 | 4.4 |

| RCMX 1606MO | 16 | 16 | 6.35 | 5.5 |

| RCMX 2006MO | 20 | 20 | 6.35 | 6.5 |

| RCMX 2507MO | 25 | 25 | 7.94 | 7.2 |

| RCMX 3509MO | 32 | 32 | 9.52 | 9.5 |

Example: RCMX 1204MO

- Round shape: with multiple cutting edges.

- 0 度間隙角 (or potentially a slight positive angle)

- Medium tolerance.

- Manufacturer-specific chipbreaker and hole configuration.

- 12mm inscribed circle diameter (approx. 0.47″ in inches)

- “04” and “MO” will have manufacturer-specific meanings for thickness, edge style, etc.

硬質合金刀片背後的科學:鎢鋼刀片的製造過程及強度原因

硬質合金刀片是目前用途最廣且最耐用的切削工具。但它們是如何製成的呢?是什麼讓它們如此堅固?在本影片中,我們將探討硬質合金刀片背後的科學,從碳化鎢的特性到製造過程。

我們的生產能力