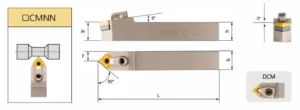

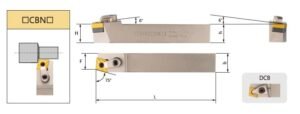

CNMG 刀片座

CNMG 刀片刀把是一種廣泛使用的車削刀把,專門用來穩固夾持 CNMG 型可轉位刀片。根據 ISO 標準,"CNMG "是指菱形刀片,具有 80 度的刀尖角、間隙角、中性切削動作及中央安裝孔。這些刀片具有高度的通用性,通常用於鋼材、不銹鋼及鑄鐵等多種材質的中到重切削粗加工及半精加工。

CNMG 刀桿的主要功能是提供一個堅固且穩定的平台,以便在加工過程中使用。 CNMG車削刀具.這可確保精確的材料去除率、良好的切屑控制及最佳的表面光潔度。刀把具有精密加工的刀槽,其形狀及尺寸與CNMG刀片完全吻合,可安全且可重複夾持。通常會使用螺絲或槓桿機構來固定刀片,即使在強大的切削力下,也能防止加工過程中任何不必要的移動或震動。

CNMG刀片因其強韌的切削刃及每片刀片有四個切削刃(每邊兩個),提供極佳的刀具壽命及成本效益而廣受歡迎。相應的CNMG刀片刀把設計使用方便,可快速有效地進行刀片分度或更換,從而減少機器停機時間。這些刀把有多種刀柄尺寸與配置,可適用於不同的機床類型與加工應用。選擇 CNMG 刀片刀把時,請考慮以下需求 CNMG 刀片座規格 例如刀柄尺寸和導角,對於最佳性能至關重要。

常見問題

"CNMG "是 ISO 標誌,表示特定的菱形 (80 度) 切削刀片,具有間隙角及中性切削動作。

它可夾持 CNMG 型可轉換式切削刀片,刀片呈菱形,刀尖角度為 80 度。

可在各種材料上進行中型至重型粗加工和半精加工。

切削刃強韌,每個刀片有四個切削刃,切屑控制良好,適用於各種材料。

考慮機床所需的刀柄尺寸、車削作業類型、加工材料以及所需的前角。檢查 CNMG 刀片座規格 在此非常重要。

常見尺寸包括 1/2 吋、5/8 吋、3/4 吋、1 吋,以及公制等效尺寸,適用於各種機床刀把。

是的,只要有適當的 CNMG 刀片等級與幾何形狀,就可以用於半精加工,甚至某些精加工應用。

剛性、安全的夾持、精確的刀片袋,以及與您的機器和刀片相容。檢視 CNMG 刀片座規格 會有幫助。

是的,刀把有多種導角可供選擇,可針對不同的車削任務發揮最佳效能。

CNMG 刀片座規格

- 刀柄尺寸(系統稱號): 這是指刀柄與機床刀塔或刀桿配合的尺寸。常見的刀柄尺寸單位為英吋(例如:1/2″、5/8″、3/4″、1″)或公釐(例如:12mm、16mm、20mm、25mm)。這對於與您的機器相容至關重要。

- 總長度: 刀架的總長度,在某些加工設定中,對於間隙和距離很重要。

- 插入尺寸指定: 指定刀把適用的CNMG刀片的確切尺寸與幾何形狀。例如,您可能會看到 "for CNMG120404 「這樣的規格,其中 」12 「指的是切削刃長度,」04 「指的是厚度,」04 "指的是刀尖半徑(在此範例中,依照一般的解釋)。不同的CNMG刀片尺寸需要不同的刀把。

- 前角(切削刃角): 這是刀片切削刃與進給方向的角度。不同的導程角適用於各種車削加工,例如端面車削、肩扛車削或一般車削。CNMG 刀把常見的導程角可能是 0 度、5 度或其他。

- 切割方向(手): 表示刀架是設計用於右側切削或左側切削。這決定了刀具沿著工件進給的方向。

- 冷卻液供應: 指定刀架是否有內冷卻通道,將冷卻液導向切削區。這有助於排屑、降低切削溫度及提高刀具壽命。您可能會看到「有內冷卻」或「無內冷卻」等指定。

- 夾持系統: 描述將CNMG刀片固定在刀座上的方法。常見的夾持系統包括螺絲鎖緊、槓桿鎖緊或楔入式夾持。

- 工具樣式/名稱: 製造商通常有自己特定的編碼系統或型號,可進一步定義刀架的特性和預期用途。

- 材質: 製造刀把的材質,通常是高強度合金鋼,以提高耐用性和剛性。

- 塗層: 有些刀把可能有表面塗層,以增強耐磨性、減少摩擦或改善特定材料的性能。

- 製造商: 生產刀架的公司。

聯絡我們

請注意 我們是批發供應商,有最低訂購量限制。