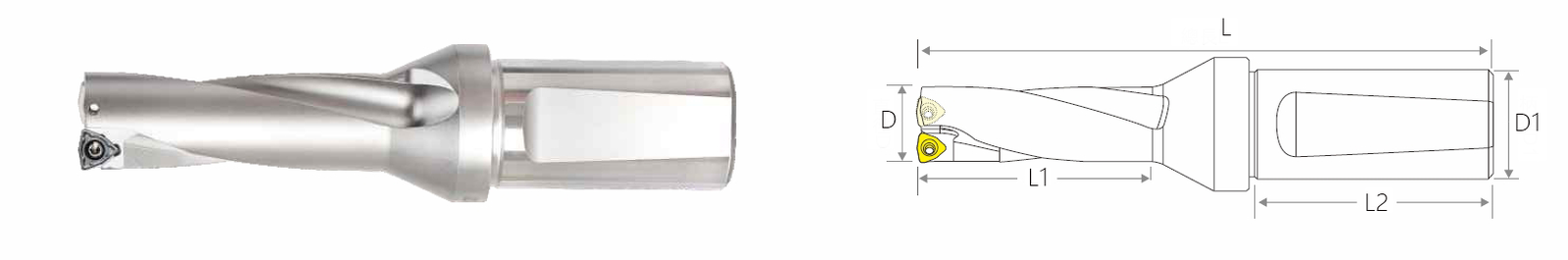

U 型鑽頭 5D 鑽體 32mm 夾持 SP 系列刀片

1. Use SP series carbide inserts

2.5D U Drill Body

3. Use H13 Steel as raw material. Processed after quenching, high hardness, good rigidity, not easy to damage.

4. Double spiral cooling structure, longer insert life.

- Indexable Carbide Inserts: This is a defining feature. U drills utilize replaceable carbide inserts as their cutting edges. These inserts typically have multiple cutting points and can be rotated or replaced individually when they become worn, eliminating the need to resharpen or replace the entire drill bit. This significantly reduces downtime and tooling costs.

- U-Shaped Flute Design: The distinctive U shape of the flutes is optimized for efficient chip evacuation. This design allows for a smooth and rapid removal of chips from the cutting zone, preventing chip accumulation and reducing the risk of tool breakage, especially in deeper holes.

- Through-Tool Coolant Channels: Most U drills are designed with internal channels that deliver coolant directly to the cutting edges. This provides effective cooling and lubrication, which helps to control heat, reduce friction, improve chip evacuation, and extend insert tool life.

- Rigid Tool Body: The drill body is typically made from hardened steel, providing high rigidity and stability during the drilling process. This rigidity allows for higher cutting speeds and feed rates compared to conventional drills, leading to increased productivity.

- Dual Cutting Edges: U drills typically employ two inserts: a center insert and a peripheral insert. This configuration ensures balanced cutting forces and contributes to better hole quality, including improved roundness and straightness.

- 自定心能力: The design of U drills often provides a self-centering effect, allowing them to start drilling directly on a workpiece without the need for a pre-drilled center hole in many applications.

- 多功能性: With various insert geometries and grades available, U drills can be used to machine a wide range of materials, including steel, stainless steel, cast iron, aluminum, and other non-ferrous metals.

- Improved Hole Quality: The combination of a rigid body, effective chip evacuation, and precise inserts results in holes with better dimensional accuracy, surface finish, and straightness, often reducing or eliminating the need for secondary finishing operations like boring or reaming.

| Model No | (L1/D) | (L1) | (L) | (D) | D1/L2 | 插入 | 螺絲 | 扳手 |

|---|---|---|---|---|---|---|---|---|

| SP07-5D-25-C32A | 5D | 125 | 211 | 25 | 32/60 | SPMG07T308 | M2.5x7L | T8 |

| SP07-5D-25.5-C32A | 5D | 127.5 | 213.5 | 25.5 | 32/60 | |||

| SP07-5D-26-C32A | 5D | 130 | 216 | 26 | 32/60 | |||

| SP07-5D-26.5-C32A | 5D | 132.5 | 218.5 | 26.5 | 32/60 | |||

| SP07-5D-27-C32A | 5D | 135 | 221 | 27 | 32/60 | |||

| SP07-5D-27.5-C32A | 5D | 137.5 | 223.5 | 27.5 | 32/60 | |||

| SP07-5D-28-C32A | 5D | 140 | 226 | 28 | 32/60 | |||

| SP07-5D-28.5-C32A | 5D | 142.5 | 228.5 | 28.5 | 32/60 | |||

| SP09-5D-29-C32A | 5D | 145 | 231 | 20 | 32/60 | SPMG090408 | M3.5x10L | T15 |

| SP09-5D-29.5-C32A | 5D | 147.5 | 233.5 | 29.5 | 32/60 | |||

| SP09-5D-30-C32A | 5D | 150 | 236 | 30 | 32/60 | |||

| SP09-5D-30.5-C32A | 5D | 152.5 | 238.5 | 30.5 | 32/60 | |||

| SP09-5D-31-C32A | 5D | 155 | 241 | 31 | 32/60 | |||

| SP00-5D-31.5-C32A | 5D | 157.5 | 243.5 | 31.5 | 32/60 | |||

| SP09-5D-32-C32A | 5D | 160 | 246 | 32 | 32/60 | |||

| SP09-5D-32.5-32A | 5D | 162.5 | 248.5 | 32.5 | 32/60 | |||

| SP09-5D-33-C32A | 5D | 165 | 251 | 33 | 32/60 | |||

| SP09-5D-335-C32A | 5D | 167.5 | 253.5 | 33.5 | 32/60 | |||

| SP09-50-34-C32A | 5D | 170 | 256 | 34 | 32/60 | |||

| SP09-5D-34.5-C32A | 5D | 172.5 | 258.5 | 34.5 | 32/60 | |||

| SP09-5D-35-C32A | 5D | 175 | 261 | 35 | 32/60 | |||

| SP09-50-35.5-C32A | 5D | 177.5 | 263.5 | 35.5 | 32/60 | |||

| SP09-5D-36-C32A | 5D | 180 | 266 | 36 | 32/60 | |||

| SP09-50-36.5-C32A | 5D | 182.5 | 268.5 | 36.5 | 32/60 | |||

| SP11-5D-37-C32A | 5D | 185 | 271 | 37 | 32/60 | SPMG110408 | M4x10L | T20 |

| SP11-5D-37.5-C32A | 5D | 187.5 | 273.5 | 37.5 | 32/60 | |||

| SP11-50-38-C32A | 5D | 190 | 276 | 38 | 32/60 | |||

| SP11-5D-38.5-C32A | 5D | 192.5 | 278.5 | 38.5 | 32/60 | |||

| SP11-5D-39-C32A | 5D | 195 | 281 | 39 | 32/60 | |||

| SP11-5D-39.5-C32A | 5D | 197.5 | 283.5 | 39.5 | 32/60 | |||

| SP11-5D-40-C32A | 5D | 200 | 286 | 40 | 32/60 | |||

| SP11-5D-40.5-C32A | 5D | 202.5 | 288.5 | 40.5 | 32/60 | |||

| SP11-5D-41-C32A | 5D | 205 | 291 | 41 | 32/60 | |||

| SP11-5D-41.5-C32A | 5D | 207.5 | 293.5 | 41.5 | 32/60 |