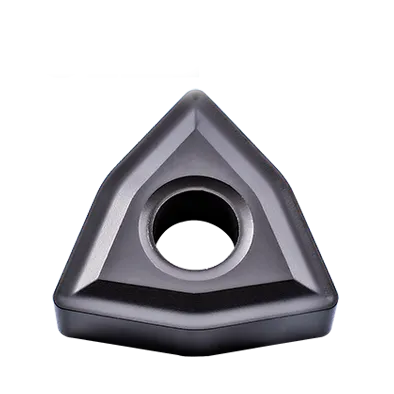

WNMG insert

WNMG insert angle : 0° Negative Rake Insert with double-sided Chipbreaker;

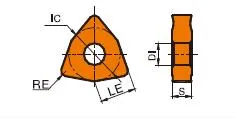

WNMG carbide insert inscribed circle (IC) of 9.525mm/12.7mm, thickness of 3.97mm/4.76mm, and corner (nose) radius of 0.2mm/0.4mm/0.8mm/1.2mm;

Machining Scene:Roughing machining/Semi-finish machining/Finishing machining;

Workpiece materials: Carbon and alloy steel, stainless steel and high temperature alloys, steel and cast iron;

Matching WNMG insert Holder: DWLNR/L, PWLNR/L, PWLNR/L;

WNMG carbide insert sizes:(ISO) WNMG06t304; WNMG06t308; WNMG060404; WNMG060408; WNMG080404; WNMG080408; WNMG080412;

(ANSI) WNMG331/ WNMG332/ WNMG431/ WNMG432;

ürün tanıtımı

WNMG Insert can deal with multiple operations by combining different chip breakers and grades.

Key Features

- Şekil: WNMG inserts have a trigon shape (equilateral triangle) with an 80° included angle. This robust shape offers three cutting edges for cost-effectiveness.

- Neutral Rake Angle: The cutting face is neither positive nor negative, but at a 0° angle to the cutting edge. This provides a strong edge suitable for various materials and operations.

- Açıklık Açısı: Often around 5-7° to prevent the insert rubbing on the workpiece.

- Advanced Chipbreakers: WNMG inserts feature complex chipbreaker geometries on one or both sides, significantly influencing chip formation for specific materials and applications.

- Kaplamalar: Commonly coated with materials like TiN, TiCN, AlTiN, and others for improved wear resistance and longevity.

WNMG insert Specification

Understanding the WNMG Code

The letters and numbers in the WNMG designation reveal crucial information:

- W: Trigon shape with an 80° included angle

- N: Neutral (0°) rake angle

- M: Tolerance class (indicates precision of size)

- G: Indicates the specific hole and chipbreaker design (varies by manufacturer)

Sayılar:

- Usually the first two numbers represent the inscribed circle (size of the triangle) in sixteenths of an inch (or directly in millimeters for ISO codes).

- Üçüncü sayı bir inçin onaltıda biri cinsinden kalınlığı temsil eder.

- Son sayı genellikle burun yarıçapını gösterir (daha küçük, daha keskin anlamına gelir).

WNMG insert holder

PWLNR/L (KAPR95°)

MWLNR/L (KAPR95°)

Carbide VNMG Insert Dimensions (ISO AND ANSI)

| WNMG INSERT SIZES | ||||

|---|---|---|---|---|

| ISO Designation | ANSI Designation | Yazılı Çember (IC) | Kalınlık | Köşe yarıçapı |

| WNMG 060404 | WNMG331 | 6.35mm (0.25") | 3.18mm (0.125") | 0.4mm (0.016") |

| WNMG 060408 | WNMG332 | 6.35mm (0.25") | 3.18mm (0.125") | 0.8mm (0.031") |

| WNMG060412 | WNMG333 | 6.35mm (0.25") | 3.18mm (0.125") | 1.2mm(0.047'') |

| WNMG 080404 | WNMG431 | 8mm (0.315") | 4.76mm (0.187") | 0.4mm (0.016") |

| WNMG 080408 | WNMG432 | 8mm (0.315") | 4.76mm (0.187") | 0.8mm (0.031") |

| WNMG080412 | WNMG433 | 8mm (0.315") | 4.76mm (0.187") | 1.2mm(0.047'') |

Example: WNMG 080408 (ISO)

- Trigon shape, neutral rake insert.

- 12,7 mm'lik yazılı daire (yaklaşık 1/2)″).

- 4,76 mm kalınlık (yaklaşık 3/16)″).

- Özel talaş kırıcı/delik tasarımı.

Sıkça Sorulan Sorular

Choose a WNMG insert based on:

- Workpiece Material: Match the insert grade to your material.

- Type of Turning Operation: Roughing needs larger nose radius for strength, finishing needs smaller radius for better surface finish.

- Chip Control: Choosing the perfect chipbreaker geometry is crucial with WNMGs to optimize the cutting process.

Important Considerations

- WNMG inserts are incredibly versatile, but the key to maximizing performance lies in selecting the right chipbreaker for your specific operation and material. Refer to manufacturer documentation for details.

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Karbür uçlar mevcut en çok yönlü ve dayanıklı kesici takımlardan bazılarıdır. Peki nasıl yapılıyorlar? Peki onları bu kadar güçlü kılan şey nedir? Bu videoda tungsten karbürün özelliklerinden üretim sürecine kadar karbür kesici uçların arkasındaki bilimi keşfedeceğiz.

Üretim Yeteneğimiz

In modern manufacturing, high-performance carbide inserts are indispensable tools, laying the foundation for efficient and precise metal processing. However, these exceptional inserts do not come into existence on their own; they are supported by the unwavering support of advanced machinery.