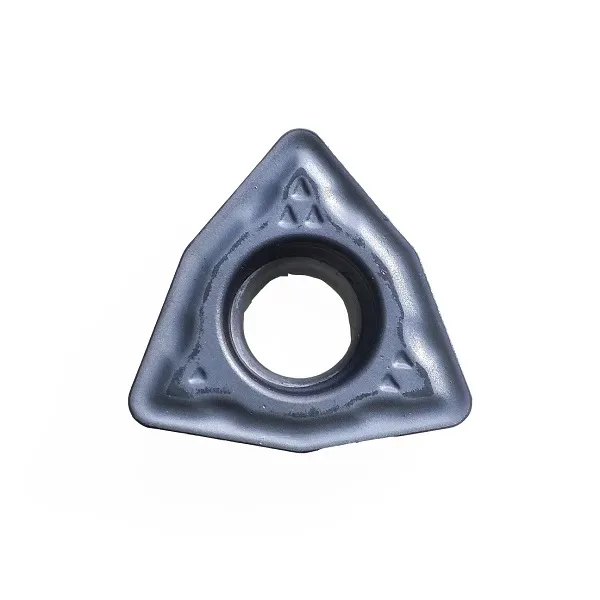

Unique economical WCMT Insert

- 드릴 인서트입니다.

- Range size: WCMT030208,WCMT040208,WCMT050308,WCMT06T308,WCMT080412.

- 범위 작업 재료: P,K,M,S

- 고품질 원자재로 제작되고 발저스로 코팅된 인서트는 더 오래 지속되고 내구성이 뛰어납니다.

- Provides stable and high quality drilling with balanced design

- New coating technology achieves long tool life with improved fracture and wear resistance

WCMT Insert size charts

| 모델 | L | IC | S | d1 | RE |

| CWMT030208-TM FPA005 | 3.8 | 5.56 | 2.38 | 2.8 | 0.8 |

| CWMT040208-TM FPA005 | 4.3 | 6.35 | 2.38 | 3.1 | 0.8 |

| CWMT050308-TM FPA010 | 5.4 | 7.94 | 3.18 | 3.2 | 0.8 |

| CWMT06T308-TM FPA010 | 6.5 | 9.525 | 3.97 | 3.7 | 0.8 |

| CWMT080412-TM FPA010 | 8.7 | 12.7 | 4.76 | 4.3 | 1.2 |

How to choose right WCMT insert for u drill body

| U DRILL | Diameter Range | Suitable wcmt insert | 나사 | 렌치 |

| 2D/3D/4D/5D | 14-19.5 | WCMT030208 | M2.5 | T8 |

| 20-24.5 | WCMT040208 | M2.5 | T8 | |

| 25-30.5 | WCMT050308 | M3. | T10 | |

| 31-41.5 | WCMT06T308 | M3.5 | T15 | |

| 42-60 | WCMT080412 | M4 | T15 |

Recommended Cutting Conditions For WCMT Insert

| 작업 자료 | Vam/min) | 피드(mm/회전) | |||||||||

| Φ12.5~Φ15 | Φ15.5~Φ21.5 | Φ22~Φ27.5 | Φ28~Φ33 | Φ34~Φ41 | Φ42~Φ50 | Φ50~Φ60 | Φ60~Φ75 | Φ75~Φ80 | |||

| P | (-0.25%) 비합금 강철 | 180-250 | 0.05-0.08 | 0.06-0.10 | 0.06-0.12 | 0.07-0.13 | 0.08-0.15 | 0.08-0.16 | 0.06-0.12 | 0.08-0.12 | 0.08-0.12 |

| (0.25%-) 저합금강 | 160-220 | 0.06-0.12 | 0.08-0.15 | 0.10-0.18 | 0.12-0.22 | 0.12-0.24 | 0.13-0.25 | 0.10-0.14 | 0.12-0.18 | 0.11-0.18 | |

| (-HB300) 저합금강 | 150-220 | 0.06-0.12 | 0.08-0.14 | 0.10-0.18 | 0.12-0.22 | 0.12-0.23 | 0.13-0.24 | 0.08-0.15 | 0.10-0.18 | 0.10-0.18 | |

| (HB300-) 고합금 강철 | 130-180 | 0.06-0.10 | 0.08-0.15 | 0.10-0.20 | 0.12-0.23 | 0.12-0.24 | 0.13-0.25 | 0.08-0.14 | 0.09-0.15 | 0.09-0.14 | |

| M | 스테인리스 스틸 | 170-240 | 0.05-0.10 | 0.06-0.12 | 0.08-0.15 | 0.09-0.16 | 0.10-0.17 | 0.11-0.19 | 0.06-0.13 | 0.08-0.15 | 0.08-0.14 |

| K | 회색 주철 | 180-250 | 0.06-0.12 | 0.08-0.16 | 0.12-0.20 | 0.15-0.25 | 0.16-0.28 | 0.18-0.30 | 0.12-0.20 | 0.15-0.20 | 0.15-0.20 |

| 연성 주철 | 130-200 | 0.06-0.10 | 0.08-0.15 | 0.10-0.18 | 0.12-0.20 | 0.15-0.23 | 0.16-0.25 | 0.10-0.15 | 0.09-0.18 | 0.10-0.18 | |

| N | 알루미늄 | 330-380 | 0.06-0.14 | 0.08-0.15 | 0.10-0.20 | 0.12-0.22 | 0.14-0.23 | 0.15-0.26 | 0.14-0.20 | 0.14-0.23 | 0.15-0.23 |

| S | 티타늄 합금강 | 30-60 | 0.05-0.10 | 0.06-0.14 | 0.08-0.18 | 0.10-0.22 | 0.12-0.22 | 0.14-0.24 | 0.10-0.15 | 0.1-0.15 | 0.1-0.15 |