先端交換式ドリルの主な特長

- モジュラー設計: RTD の基本的な特性は、耐久性のあるドリル本体と交換可能な切削チップで構成されるモジュラー設計です。これにより、ドリル全体を交換する必要がなく、チップを迅速に交換できます。

- 材質とコーティング: チップは通常、超硬などの高性能材料で作られ、耐久性と効率を高めるために窒化チタン (TiN) などの材料でコーティングされることがよくあります。

- 多彩なチップの選択: チップの幅広い選択肢があり、それぞれが特定の材料または穴あけ作業用に設計されています。これには、さまざまな形状、コーティング、グレードが含まれており、さまざまな用途にわたって最適なパフォーマンスを実現します。

明確に交換可能な先端ドリル加工をご覧ください

先端交換式ドリルは7~10等級の穴精度に達し、15*Dの深さを加工でき、対称設計で加工効率が大幅に向上し、通常のUドリルの3~4倍です。先端交換式ドリル交換式ドリルビット設計。ドリルビットの磨耗を2〜3回繰り返して使用すると、修理と研磨ができるため、経済性が大幅に向上します。

Our tip drill tool design

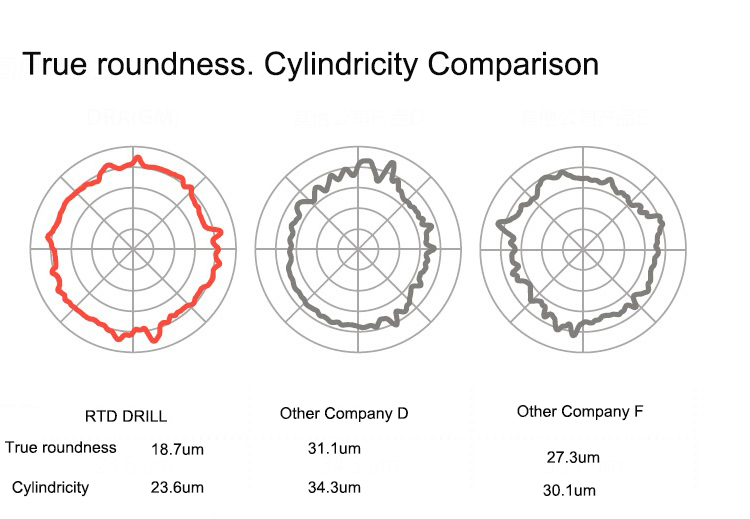

低抵抗設計で優れた穴加工精度を実現し、4つの特長で穴加工の悩みを解決し高能率加工を実現します。

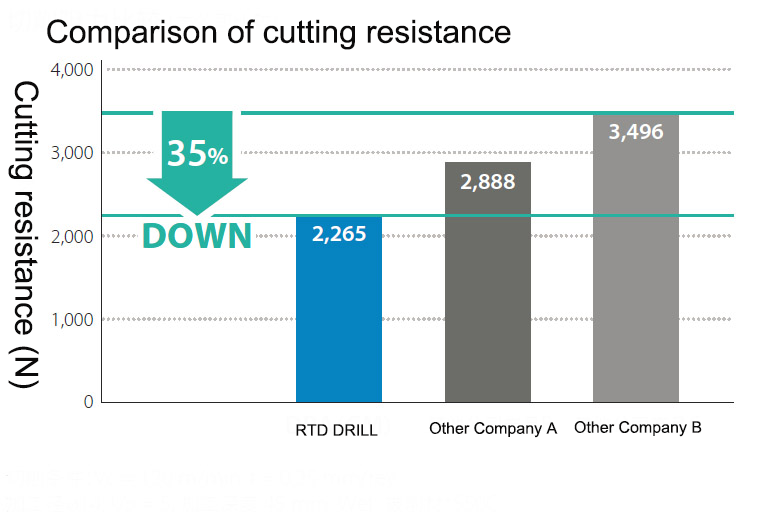

1. 低抵抗設計により穴加工精度の向上を実現

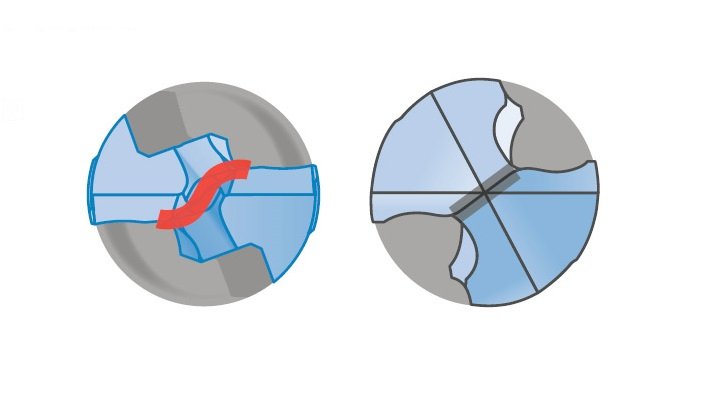

最先端の回路図

測温抵抗体ドリル

他メーカー

特殊S字カーブ切れ刃により切削抵抗を低減し、工具挿入時の振動を抑制します。

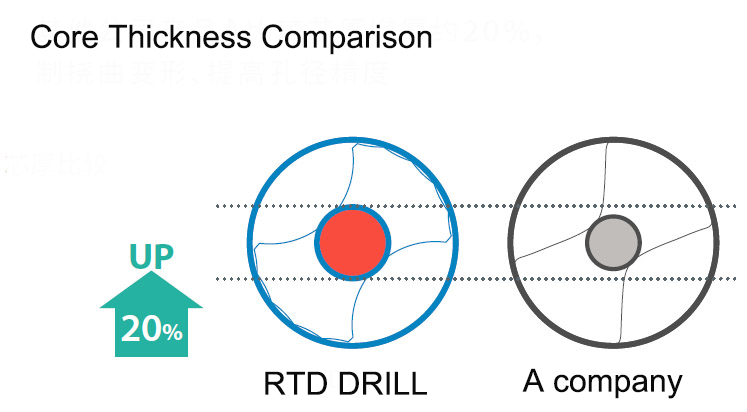

2. シャンクの芯厚を厚くし、ネジレや変形を抑制

他社比コア厚20%増’ A、ねじれ変形を抑制し、穴精度を向上

切削条件:Vc=120m/min、f=0.25mm/rev 加工径ø14、/D=5、加工深さ45mm、湿式 被削材:S50C

切削条件:Vc=120m/min、f=0.3mm/rev 加工径ø14、/D=5、加工深さ55mm、湿式 被削材:S50C

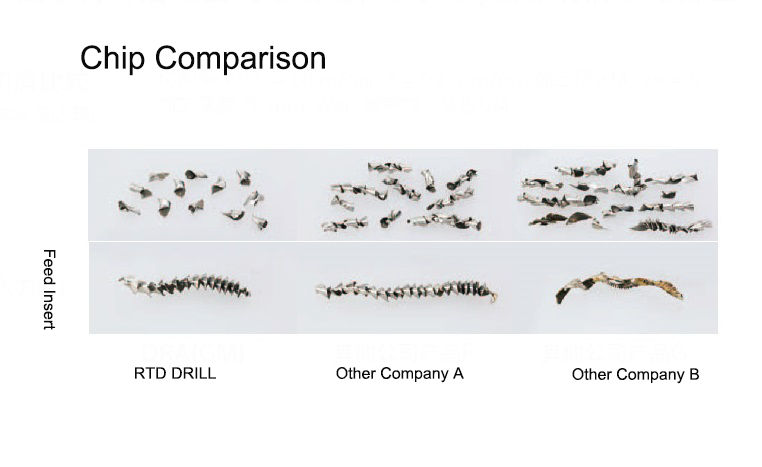

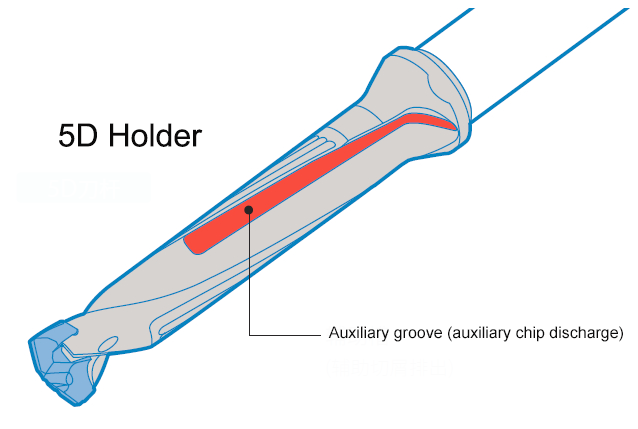

3. 微細な切りくずにより深穴加工でも優れた切りくず排出性

ツールホルダー背面の拡張補助スロット (5D、8D) により、スムーズな切りくず排出が保証されます。

切削条件:Vc=60m/min、f=0.2mm/rev 加工径ø14、/D=5、加工深さ70mm、湿式 被削材:SUS304

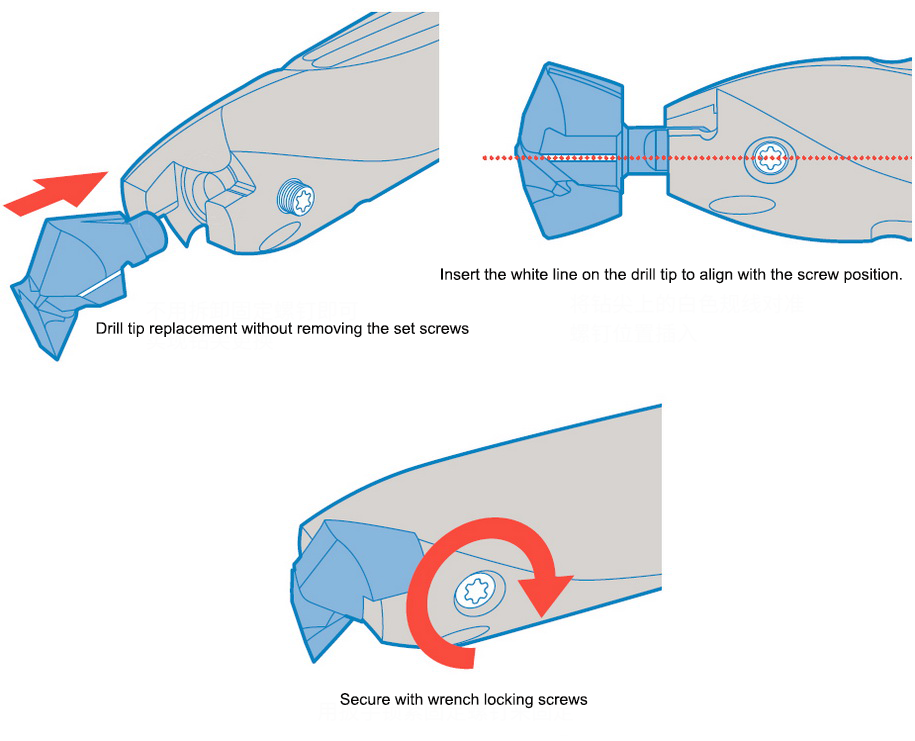

4. 簡単なドリルチップ交換

Our exchangeable tip drill tool Success Story

- ワーク:パイププレート

- 素材: S31603

- プロセス: ドリル D25.25±0.1 の貫通穴のサイズ、穴の深さ 120 mm

- マシン: ハイチ製ガントリー、スピンドル BT50

- 冷却方式:エマルジョン方式、内部冷却方式

- コレットタイプ:サイドセットシャンク

- 工具:D25.3ステンレス製先端交換式ドリル

商品 / 状態 / 商品説明

| 先端交換式ドリル | 他社 | オンミーRTD |

|---|---|---|

| N(回転数) | S720 | S720 |

| VC (m/分) | 57 | 57 |

| VF (m/分) | F90 | F90 |

| Fz (mm/z) | 0.125 | 0.125 |

| 寿命(穴数) | 300 | 432 |

| 工具寿命(m) | 36 | 52 |

| 結果: ONMY 先端交換式ドリルの寿命は競合製品より 44% 向上しました。 |

ビジネスを始めるにはONMYにお問い合わせください

当社の顧客が当社の商品やサービスをどのように認識しているかを見てみましょう。

私たちの利点

- 新しい原材料、製品の品質管理の第一歩。

- 工場直販、中間業者を拒否し、価格差を稼ぎます。

- 6S管理、標準化されたプロセス、問題のある製品を工場から排除する源。

- 専門の販売専門家が、加工の問題のほとんどを解決します。

- アフターサービスは、製品の問題を7 * 24時間保証します。