旋盤切削インサート

金属加工の分野では、旋盤切削インサートは縁の下の力持ちとして存在し、原材料を比類のない精度で静かに複雑な部品に変えます。これらの小型の交換可能な切削チップは旋盤工具ホルダーとシームレスに統合され、ワークピースと相互作用する刃先を形成します。

旋盤の切削インサートは主に炭化タングステンで作られています。炭化タングステンは、高速切削加工中に発生する激しい熱と摩擦に耐えることができる、非常に硬くて耐摩耗性の高い材料です。この優れた耐久性により、長いインサート寿命と安定した性能が保証されます。

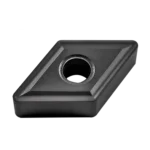

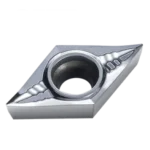

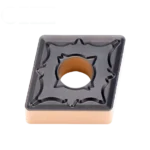

超硬旋盤工具インサートにはさまざまな形状、サイズ、グレードがあり、特定の加工用途に対応できるように細心の注意を払って設計されています。鍛造品の粗加工や精密部品の光沢仕上げなど、課題に応えるのに最適なインサートがあります。

私たちを選ぶ理由

大手旋削インサートメーカーおよび旋削インサート工場として、当社はお客様の機械加工オペレーションに明確なメリットを提供します。

調達戦略をアップグレードします。今すぐ当社の旋削インサート工場に問い合わせて、信頼できるメーカーと直接連携するメリットを体験してください。

コスト削減

中間業者を排除することで、当社の旋削チップは非常に競争力のある価格で提供されます。品質を犠牲にすることなく予算を最大限に活用します。

カスタマイズ機能

独自のインサート形状や特殊なコーティングが必要ですか?当社の社内製造により、お客様の仕様に正確に適合するカスタマイズされたソリューションが可能になります。

品質管理

私たちは生産プロセスのあらゆる段階を監督し、最高の品質基準が確実に満たされるようにします。一貫した信頼性の高いパフォーマンスを実現する当社のインサートを信頼してください。

技術的な専門知識

当社のエンジニアは旋削インサートの設計と用途について深い知識を持っています。機械加工プロセスを最適化するために、専門家のアドバイスとサポートを得てください。

大量注文能力

当社は大規模な注文を効率的に処理するための設備を備えており、必要なときに必要なインサートを常に入手できるようにします。

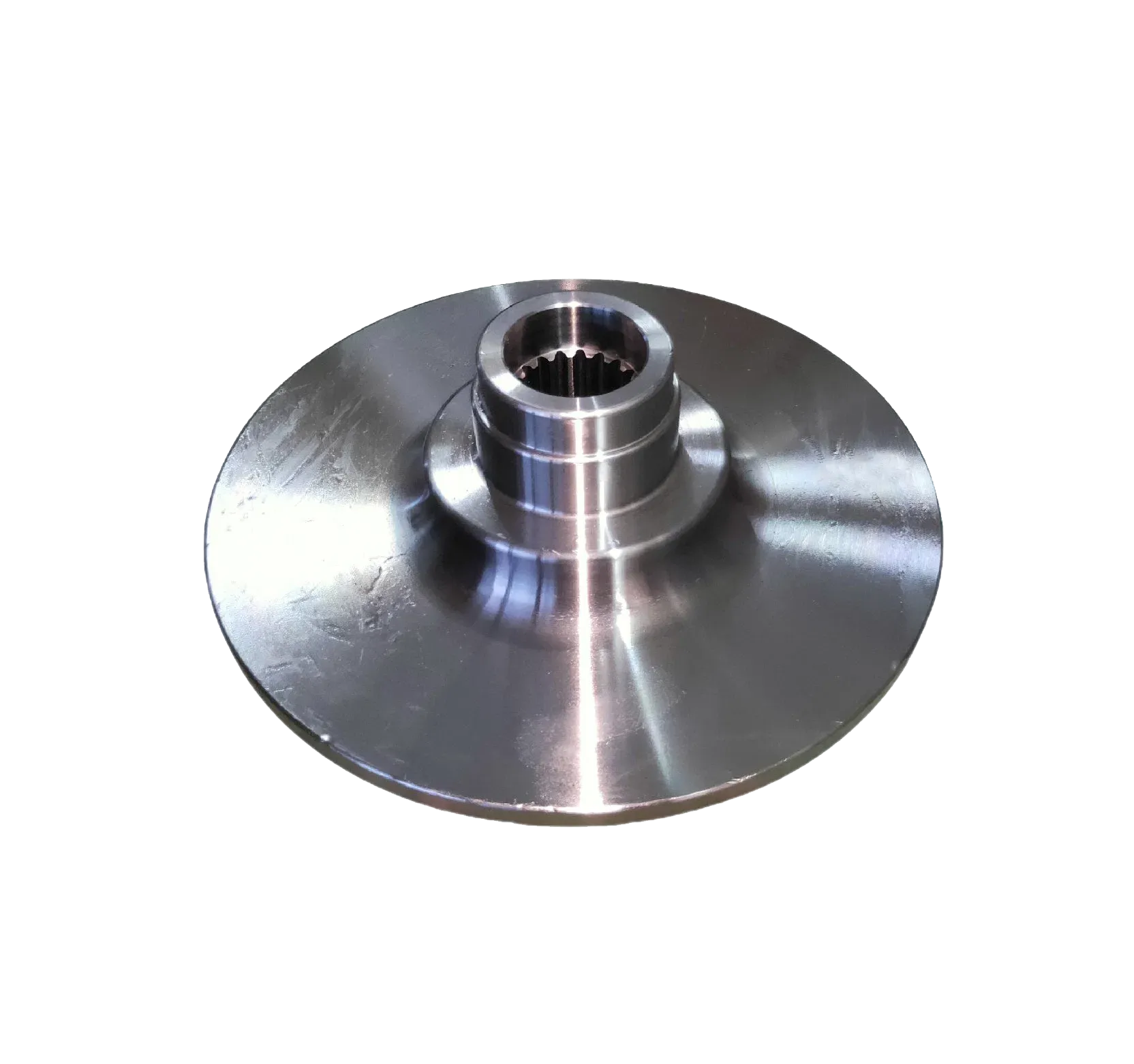

フランジプレート

用途 - P型材料旋削加工

- 被削材:40Cr、焼入れ焼戻し

- 加工方法:端面仕上げ

- 旋削インサート: DNMG150408

- 加工パラメータ:Vc=338.5m/min、f.-0、14~0.32mm/r、ap=0.2mm

- 冷却方式:水冷

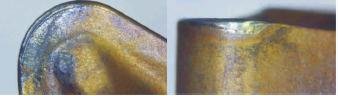

200 個のワークを加工した後、ONMY 製品は後部インサート面の摩耗量が少なく、表面品質が向上しました。

A社

オンミー

フランジプレート

用途-ステンレス鋼材旋削加工

- 被削材材質:SUS304

- 加工方法:外径・端面旋削

- 旋削インサート:VNMG160408

- 加工パラメータ: Vc=171~180m/min、fn=0.08mm/r、ap=0.30mm

- 冷却方式:水冷

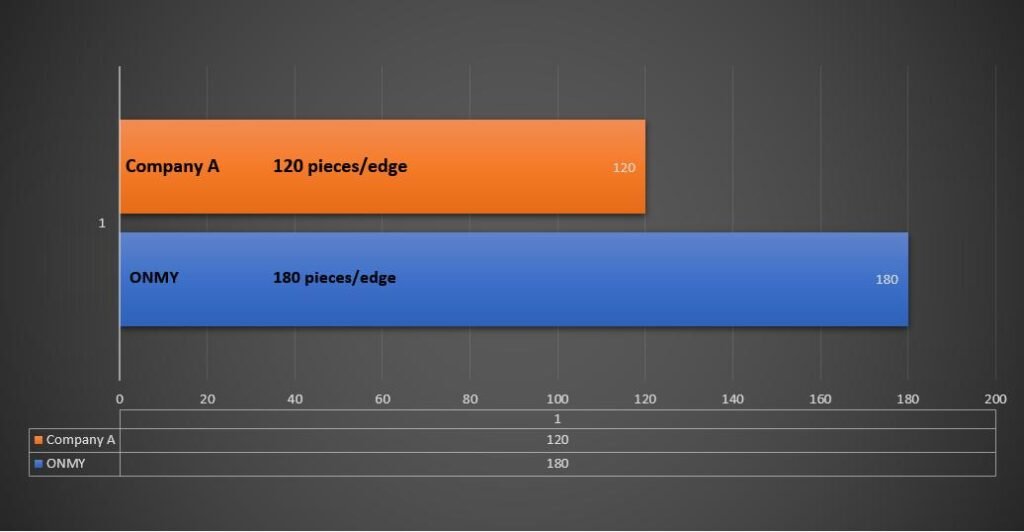

良好な加工面品位を誇るONMY製品’ 寿命が約50%延長されます。

よくある質問

当社は長年の経験を持つ旋削インサートメーカーです。当社の旋削インサート工場には 30 台以上の研削盤があり、より要求の厳しい製品向けに 5 台の Anka 研削盤が備えられています。当社の工場の製品は出荷前に100%検査されています。もちろん輸出専門の商社もございます。

はい、当社の旋削インサートは業界標準を満たすかそれを上回るように製造されており、すべての製品で高品質と信頼性が保証されています。

もちろん、当社はお客様の特定のニーズや要件を満たすカスタム設計サービスを提供します。当社の専門家チームはお客様と協力して、お客様の加工用途に合わせたソリューションを作成できます。

当社では、ご注文をタイムリーに納品できるよう、合理化された生産プロセスと効率的な物流システムを導入しています。私たちのチームは、期限を守り、プロセス全体を通じて優れた顧客サービスを提供することに専念しています。

当社は顧客満足度を非常に重視しており、販売後の問題や苦情に対応する専任のカスタマーサポートチームを設けています。ご懸念がある場合は、弊社までご連絡ください。ご満足いただけるよう解決に向けて誠心誠意対応させていただきます。

プロフェッショナル機械が高品質の旋盤切削インサートを提供します

当社は、15 台以上の全自動研削盤、3 台の 5 軸研削盤、およびさまざまな検査装置を備え、最高品質のフライス工具を提供します。

この他にも複数のフライス盤を取り揃えております。なぜフライス盤が必要なのか疑問に思う人もいるかもしれません。それは、工場の設備から出てくるすべての新製品は、検査装置でサイズや刃のデータを測定するだけでなく、テストする必要があるためです。

このようにして、より包括的なテストを実施して、製品の品質と性能が要件を満たしていることを確認できます。

あなたは彼らを信頼できるでしょう

これらは当社が提携しているブランドのほんの一部です。私たちの会社は小さな分野にしか焦点を当てていないので、信頼できないかもしれません。ただし、これらのブランドをまったく初めて使用することもできます。

石油抽出、自動車製造、産業専門家など、当社のブレードは広く必要とされています。なぜなら、私たちは彼らに本当に利益をもたらすことができるからです。

私たちのブランドウォールの一員になりませんか?