Side- locking Replaceable Tip Drill

A Replaceable Tip Drill (RTD) is an advanced type of drilling tool that features a detachable cutting tip, which can be replaced when worn out or damaged. This design allows for the cutting edge of the drill to be easily swapped out, without the need to replace the entire drill body.

- High efficiency modular drill

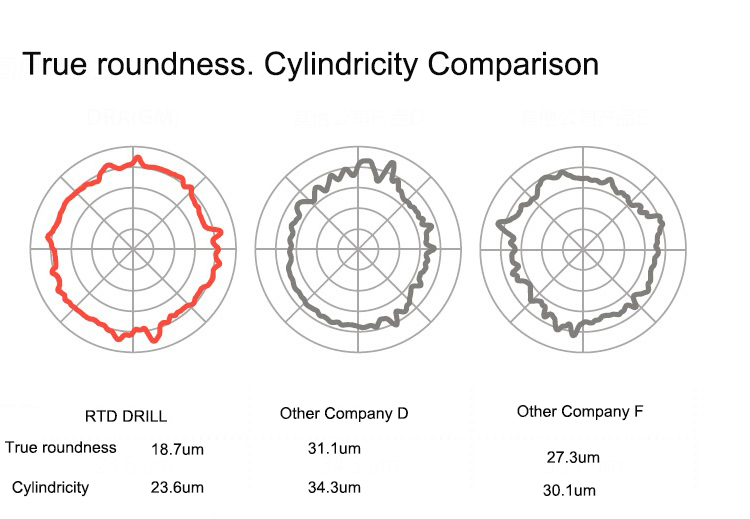

- Low drag design for superior hole accuracy

- Large core thickness to minimize flexural deformation

- Smooth deep hole machining due to finely chopped chips

- Simple tip replacement

Key features of replaceable tip drill

- Modular Design: The fundamental attribute of RTDs is their modular design, consisting of a durable drill body and a replaceable cutting tip. This allows for the rapid exchange of tips without the need to replace the entire drill.

- Material and Coating: The tips are usually made from high-performance materials such as carbide and are often coated with materials like titanium nitride (TiN) to enhance their durability and efficiency.

- Diverse Tip Selection: There is a wide selection of tips available, each designed for specific materials or drilling operations. This includes various geometries, coatings, and grades, enabling optimal performance across different applications.

See clearly replaceable tip drill machining

Replaceable tip drill can reach 7-10 grade hole accuracy, can process 15*D depth, symmetrical design can greatly improve the processing efficiency, is 3-4 times more than the ordinary U-drill.Replaceable tip drill replaceable drill bit design, when the use of the drill bit wear and tear can also be repeated 2-3 times to repair and sharpening, greatly increase the economy.

Our tip drill tool design

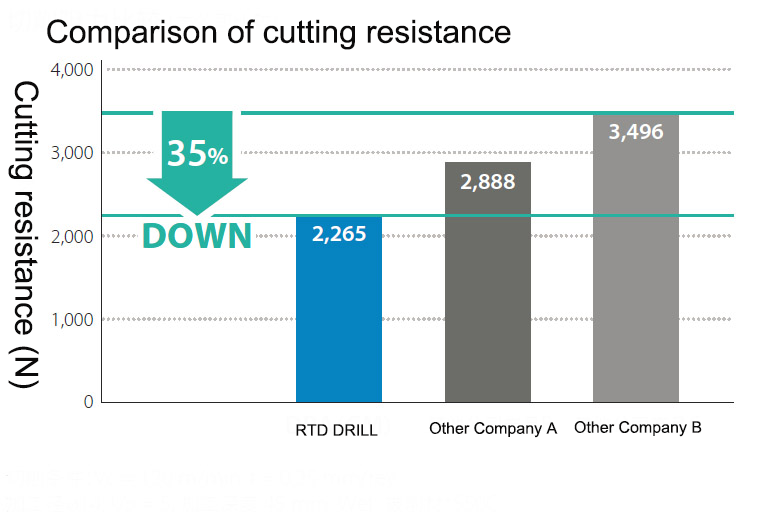

Low resistance design realizes excellent hole machining accuracy and 4 features solve hole machining problems for high efficiency machining.

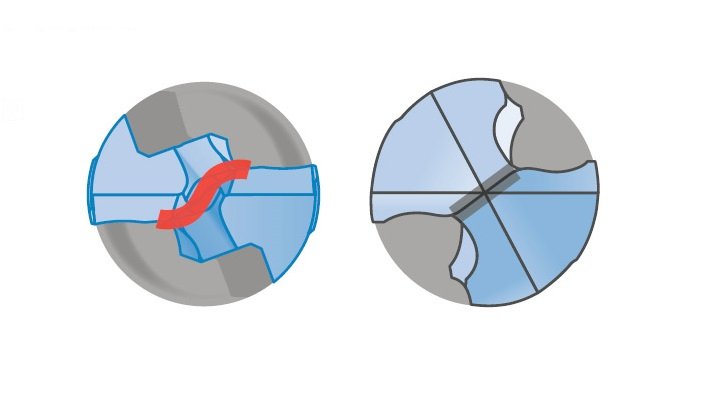

1. Low drag design realizes improved hole machining accuracy

Cutting Edge Schematic

RTD DRILL

Other manufacturer

The special S-curve cutting edge reduces cutting resistance and suppresses vibration during tool insertion.

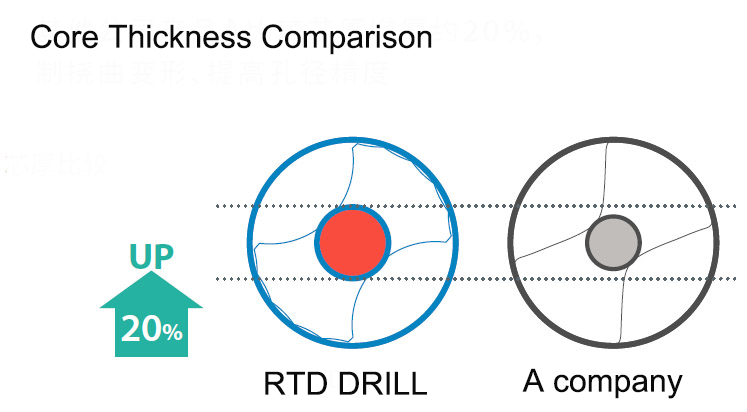

2. Large core thickness of the shank to suppress twisting and deformation

20% increase in core thickness compared to other companies’ A, suppressing torsional deformation and improving hole accuracy

Cutting conditions: Vc=120 m/min, f=0.25 mm/rev machining diameter ø14,/D=5, machining depth 45 mm, Wet Material to be cut: S50C

Cutting conditions: Vc=120 m/min, f=0.3 mm/rev machining diameter ø14,/D=5, machining depth 55 mm, Wet Material to be cut: S50C

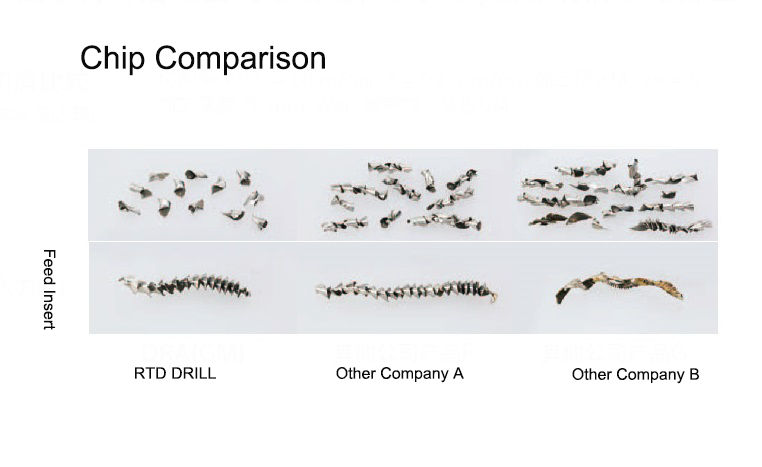

3. Excellent chip evacuation even in deep hole machining due to fine cut-off chips

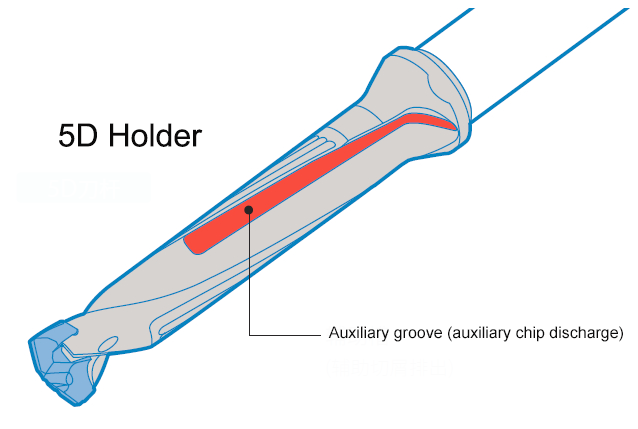

Extended auxiliary slots (5D, 8D) on the rear face of the toolholder ensure smooth chip evacuation.

Cutting conditions: Vc=60 m/min, f=0.2 mm/rev machining diameter ø14,/D=5, machining depth 70 mm, Wet Material to be cut: SUS304

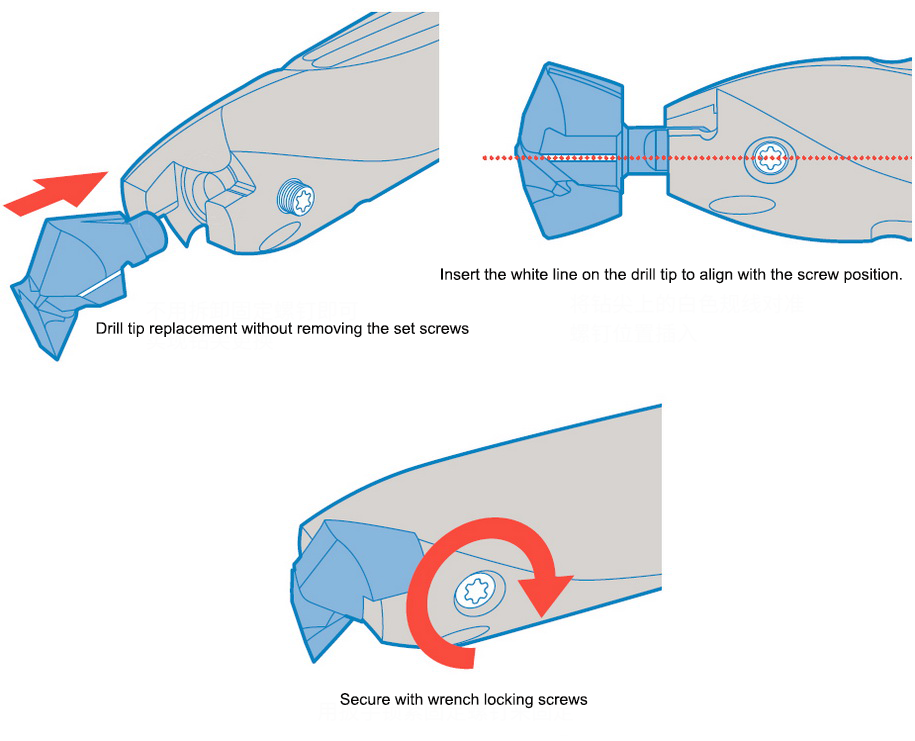

4. simple drill tip replace

Our exchangeable tip drill tool Success Story

- Workpiece: pipe plate

- Material: S31603

- Process: Drill D25.25±0.1 through-hole to size, hole depth 120mm

- Machine: Haitian gantry, spindle BT50

- Cooling method: emulsion, internal cooling

- Collet type: Side-set shank

- Tool: D25.3 stainless steel replaceable tip drill

Product / Condition / Product Description

| replaceable tip drill | other company | onmy RTD |

|---|---|---|

| N (rpm) | S720 | S720 |

| VC (m/min) | 57 | 57 |

| VF (m/min) | F90 | F90 |

| Fz (mm/z) | 0.125 | 0.125 |

| Life (number of holes) | 300 | 432 |

| Tool life (m) | 36 | 52 |

| RESULTS: Life with the ONMY replaceable tip drill was 44% better than the competition. |

Contact ONMY to Start Your Business

Have a look at how some of our clients perceive our goods and services:

Our Advantages

- New raw materials, the first step to control product quality.

- Factory direct sales, refused to middlemen earn price difference.

- 6S management, standardized process, the source to eliminate the problem products out of the factory.

- Professional sales experts solve most of your machining problems.

- After-sales guarantee any product problems 7 * 24 hours service.