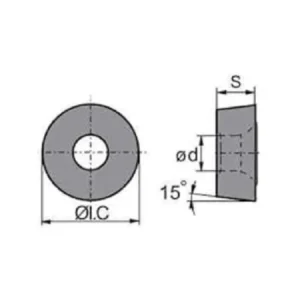

Inserto RDKW

¿Busca mejorar sus procesos de mecanizado con herramientas de corte de alto rendimiento? Las plaquitas RDKW ofrecen una precisión, durabilidad y versatilidad excepcionales para una amplia gama de aplicaciones de mecanizado. Descubra cómo las plaquitas RDWK pueden mejorar sus operaciones de fabricación y ofrecer resultados superiores.

Por qué los insertos RDWK son la mejor opción para su empresa

Precisión y exactitud excepcionales

Las plaquitas están diseñadas para un corte preciso y una gran exactitud, lo que garantiza que se consiguen las especificaciones exactas y las tolerancias estrechas necesarias para obtener resultados de calidad.

Ventajas:

- Consiga cortes precisos y acabados detallados.

- Reducir la necesidad de repeticiones y correcciones.

Durabilidad y longevidad superiores

Fabricado con carburo de alta calidad o cermet Con recubrimientos avanzados, los insertos RDWK están diseñados para soportar condiciones exigentes, lo que prolonga la vida útil y la confiabilidad de la herramienta.

Ventajas:

- Soportan fuerzas de corte y temperaturas elevadas.

- Minimice las sustituciones de herramientas y los tiempos de inactividad asociados.

Aplicaciones versátiles

Las plaquitas son versátiles y adecuadas para una gran variedad de tareas de mecanizado, entre las que se incluyen:

- Operaciones de torneado: Ideal tanto para procesos de desbaste como de acabado.

- Operaciones de fresado: Eficaz para fresado frontal, ranurado y perfilado.

- Ranurado y tronzado: Perfecta para ranurado interior y exterior, así como para operaciones de tronzado.

Ventajas:

- Adaptable a diversos materiales y condiciones de corte.

- Racionalice su inventario de herramientas gestionando múltiples aplicaciones.

Revestimientos y materiales avanzados

Con recubrimientos de alta calidad como PVD (deposición física de vapor) y CVD (deposición química de vapor), las plaquitas RDWK ofrecen una mayor resistencia al desgaste y un mejor rendimiento de corte.

Ventajas:

- Mejorar la longevidad y la eficacia de las herramientas.

- Proporcionan un rendimiento fiable en diversos entornos de mecanizado.

¿Por qué elegir nuestras plantillas?

Precisión y exactitud superiores

Corte de precisión: Las plaquitas RDWK están diseñadas con geometrías avanzadas que garantizan cortes precisos y gran exactitud. Esto es crucial para conseguir especificaciones exactas y tolerancias ajustadas en sus tareas de mecanizado. Resultados consistentes: El rendimiento consistente de las plaquitas RDWK reduce la probabilidad de errores y retrabajos, lo que conduce a resultados de mayor calidad y una mayor eficiencia de producción.

Mayor durabilidad y longevidad

Construcción robusta: Fabricadas con metal duro o cermet de alta calidad, las plaquitas RDWK están construidas para soportar grandes esfuerzos de corte y temperaturas elevadas. Esta robustez se traduce en una mayor vida útil de la herramienta. Reducción de la sustitución de herramientas: El diseño duradero y los recubrimientos avanzados ayudan a minimizar la frecuencia de los cambios de plaquita, lo que reduce el tiempo de inactividad y los costes de mantenimiento.

Versatilidad en todas las aplicaciones

Amplia gama de usos: Las plaquitas RDWK son versátiles y adecuadas para diversas operaciones de mecanizado, como torneado, fresado, ranurado y tronzado. Manejan diferentes materiales, como acero, acero inoxidable y metales no ferrosos. Adaptabilidad: Las plaquitas son eficaces tanto en procesos de desbaste como de acabado, lo que las convierte en una solución flexible para diversas necesidades de mecanizado.

Nuestra capacidad de producción