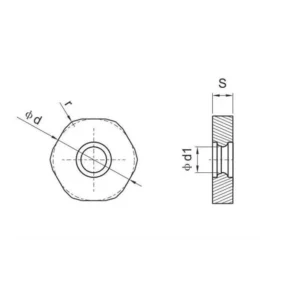

Inserto HNMX

Como proveedor líder de soluciones de fresado de vanguardia, ofrecemos una amplia gama de plaquitas BDMT diseñadas para ofrecer la máxima eficacia y durabilidad en aplicaciones industriales a gran escala. Nuestros productos se dirigen a clientes mayoristas que buscan herramientas de fresado de máxima calidad para sus operaciones.

Guía de especificaciones de la plaquita HNMX

- H: suele referirse a la forma del inserto. En este caso, 'H' suele significar forma "Hexagonal".

- N: A menudo indica un ángulo específico o una característica de holgura de la plaquita.

- M: Comúnmente significa "Medio", que puede referirse a la velocidad de avance, al diseño del rompevirutas o a otras características de corte.

- X: puede indicar una característica particular, una clase de tolerancia o una designación específica del fabricante.

Compatibilidad de la fresa HNMX

- Plaquitas de fresado Son brocas reemplazables que se utilizan para mecanizar algunos de los materiales más duros.

- Algunos de los materiales que moldean o cortan son acero, acero inoxidable, hierro fundido, materiales no ferrosos, titanio, acero templado y plástico.

- El ONMY Inserto de fresado es un inserto de alta calidad diseñado para afilar los filos de corte de las fresas frontales.

- La construcción en metal duro ofrece excelentes velocidades de arranque de material tanto en materiales duros como blandos.

- También es capaz de eliminar el exceso de material más rápidamente que las fresas tradicionales.

- El material de la plaquita de fresado ONMY HNMX es metal duro.

- Las plaquitas de fresado ONMY están diseñadas para el fresado en acero y acero inoxidable.

- Las plaquitas de fresado ONMY están diseñadas para reducir las fuerzas de corte y prolongar la vida útil de la plaquita.

Aplicaciones

Las plaquitas destacan en diversas operaciones de fresado industrial:

- Fresado frontal general

- Fresado de hombros

- Operaciones de desbaste y acabado

- Apto para materiales como acero, acero inoxidable y hierro fundido

Las plaquitas HNMX se utilizan generalmente para operaciones de fresado de alta resistencia. La forma hexagonal proporciona múltiples filos de corte, lo que permite un uso más prolongado antes de que sea necesaria su sustitución. Estas plaquitas suelen ser las preferidas por su estabilidad y capacidad para soportar grandes fuerzas de corte.

Estas plaquitas se utilizan normalmente en operaciones de fresado frontal, fresado de hombros y otras operaciones similares, especialmente cuando se trabaja con materiales duros o en situaciones que requieren altas velocidades de arranque de material.

¿Por qué elegir nuestras plantillas?

Durabilidad superior

Nuestras plaquitas HNMX se fabrican con materiales de metal duro de primera calidad, lo que garantiza una excepcional resistencia al desgaste y una mayor vida útil de la herramienta, incluso en condiciones de corte exigentes.

Rendimiento versátil

Diseñadas para destacar tanto en operaciones de desbaste como de semiacabado, nuestras plaquitas HNMX reducen la necesidad de cambios frecuentes de herramienta, mejorando la productividad global.

Solución rentable

Con seis filos de corte por plaquita, nuestro diseño HNMX ofrece una excelente relación calidad-precio, reduciendo sus costes de herramientas a lo largo del tiempo.

Indexación sencilla

Compatibles con portaherramientas estándar, nuestras plaquitas permiten un indexado rápido y sencillo, minimizando el tiempo de inactividad.

Nuestra capacidad de producción