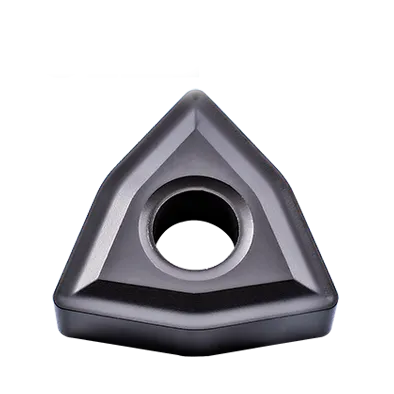

WNMG 刀片

WNMG刀片角度:0°負前角刀片,附雙面斷屑槽;

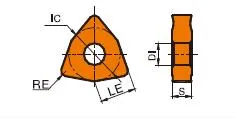

WNMG硬質合金刀片內切圓(IC)為9.525mm/12.7mm,厚度為3.97mm/4.76mm,刀尖(刀尖)半徑為0.2mm/0.4mm/0.8mm/1.2mm;

加工場景:粗加工/半精加工/精加工;

工件材質:碳鋼及合金鋼、不銹鋼及高溫合金、鋼及鑄鐵;

Matching WNMG insert Holder: DWLNR/L, PWLNR/L, PWLNR/L;

WNMG硬質合金刀片尺寸:(ISO)WNMG06t304; WNMG06t308; WNMG060404; WNMG060408; WNMG080404; WNMG080408; WNMG080412;

(ANSI) WNMG331/ WNMG332/ WNMG431/ WNMG432;

產品介紹

WNMG 刀片可以透過組合不同的斷屑槽和材質來處理多種加工。

主要特點

- 形狀: WNMG 刀片呈三角形(等邊三角形),夾角為 80°。這種堅固的形狀提供了三個切割刃,具有成本效益。

- 中性前角: 切削麵既不是正的也不是負的,而是與切削刃成0°角。這提供了適合各種材料和操作的強大優勢。

- 間隙角: 通常在 5-7° 左右,以防止刀片與工件摩擦。

- 先進斷屑槽: WNMG 刀片一側或兩側具有複雜的斷屑槽幾何形狀,顯著影響特定材料和應用的切屑形成。

- 塗料: 通常塗有 TiN、TiCN、AlTiN 等材料,以提高耐磨性和使用壽命。

WNMG 刀片規格

了解 WNMG 代碼

WNMG 名稱中的字母和數字揭示了重要訊息:

- 寬: 夾角為 80° 的三角形

- 紐: 中性 (0°) 前角

- 中號: 公差等級(表示尺寸精度)

- 克: 表示特定的孔和斷屑槽設計(因製造商而異)

數字:

- 通常前兩個數字表示內切圓(三角形的大小),以十六分之一英吋為單位(對於 ISO 代碼,則直接以毫米為單位)。

- 第三個數字代表厚度(以十六分之一英吋為單位)。

- 最後一個數字通常表示刀尖半徑(越小意味著越鋒利)。

WNMG 刀片架

PWLNR/L (KAPR95°)

MWLNR/L (KAPR95°)

硬質合金 VNMG 刀片尺寸(ISO 和 ANSI)

| WNMG 刀片尺寸 | ||||

|---|---|---|---|---|

| ISO 名稱 | ANSI 名稱 | 內切圓 (IC) | 厚度 | 轉角半徑 |

| 西寧MG 060404 | WNMG331 | 6.35mm (0.25") | 3.18mm (0.125") | 0.4mm (0.016") |

| 西寧MG 060408 | WNMG332 | 6.35mm (0.25") | 3.18mm (0.125") | 0.8mm (0.031") |

| WNMG060412 | WNMG333 | 6.35mm (0.25") | 3.18mm (0.125") | 1.2mm(0.047'') |

| 西寧MG 080404 | WNMG431 | 8mm (0.315") | 4.76mm (0.187") | 0.4mm (0.016") |

| 西寧MG 080408 | WNMG432 | 8mm (0.315") | 4.76mm (0.187") | 0.8mm (0.031") |

| WNMG080412 | WNMG433 | 8mm (0.315") | 4.76mm (0.187") | 1.2mm(0.047'') |

經常問的問題

根據以下因素選擇 WNMG 刀片:

- 工件材質: 將刀片牌號與您的材質相符。

- 車削操作類型: 粗加工需要較大的刀尖半徑以獲得強度,精加工需要較小的半徑以獲得更好的表面光潔度。

- 晶片控制: 選擇完美的斷屑槽幾何形狀對於 WNMG 優化切削過程至關重要。

重要考慮因素

- WNMG 刀片的用途極為廣泛,但最大限度提高性能的關鍵在於為您的特定操作和材料選擇合適的斷屑槽。有關詳細信息,請參閱製造商文件。

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

硬質合金刀片是目前最通用、最耐用的切削工具之一。但它們是如何製作的呢?是什麼讓他們如此強大?在本影片中,我們將探索硬質合金刀片背後的科學,從碳化鎢的特性到製造流程。

我們的生產能力

在現代製造業中,高性能硬質合金刀片是不可或缺的工具,為高效、精確的金屬加工奠定了基礎。然而,這些特殊的插入物並不是自行存在的。他們得到了先進機械的堅定支持。